JeepParts

My Garage

My Account

Cart

OEM Dodge Challenger Seat Belt

Seat Safety Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

43 Seat Belts found

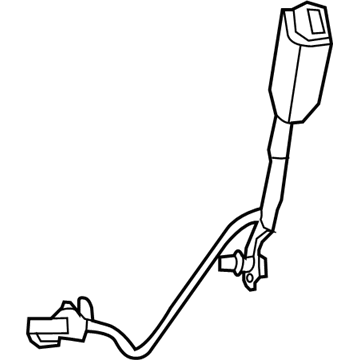

Dodge Challenger Buckle End, Black, Front Driver Side Part Number: 6MS011X9AA

$215.27 MSRP: $317.00You Save: $101.73 (33%)Ships in 1-3 Business Days

Dodge Challenger Buckle End, Black, Front Passenger Side Part Number: 6MS001X9AA

$226.60 MSRP: $334.00You Save: $107.40 (33%)Ships in 1-3 Business Days

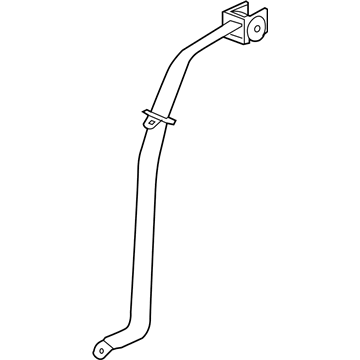

Dodge Challenger Lap & Shoulder Belt, Black, Rear Outer Part Number: 5UZ23DX9AC

$140.49 MSRP: $208.00You Save: $67.51 (33%)

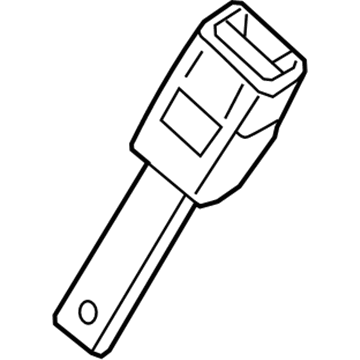

Dodge Challenger Buckle End, Front Inner Driver Side Part Number: 1HZ171DVAF

$348.08 MSRP: $508.00You Save: $159.92 (32%)Ships in 1-3 Business Days

Dodge Challenger Buckle End, Black, Front Inner Passenger Side Part Number: 1HZ101X9AF

$337.63 MSRP: $498.00You Save: $160.37 (33%)Ships in 1-3 Business Days

Dodge Challenger Buckle End, Black, Front Inner Driver Side Part Number: 1HZ171X9AF

$360.68 MSRP: $526.00You Save: $165.32 (32%)Ships in 1-3 Business Days

Dodge Challenger Buckle End, Gray, Front Inner Driver Side Part Number: 1BX251DVAB

$87.69 MSRP: $130.00You Save: $42.31 (33%)Ships in 1-3 Business DaysDodge Challenger Lap & Shoulder Belt, Black, Rear Part Number: 6KE10DX9AC

$98.57 MSRP: $146.00You Save: $47.43 (33%)Ships in 1-3 Business DaysDodge Challenger Lap & Shoulder Belt, Rear Center Part Number: 6KE741X9AB

$138.23 MSRP: $204.00You Save: $65.77 (33%)Ships in 1-3 Business DaysDodge Challenger Lap & Shoulder Belt, Front Part Number: 1SG57DX9AK

$362.97 MSRP: $529.00You Save: $166.03 (32%)Ships in 1-2 Business DaysDodge Challenger Lap & Shoulder Belt, Front Part Number: 1SG581R9AK

$181.28 MSRP: $268.00You Save: $86.72 (33%)Dodge Challenger Lap & Shoulder Belt, Rear Outer Part Number: 1HU13XDVAD

$230.00 MSRP: $339.00You Save: $109.00 (33%)Ships in 1-3 Business DaysDodge Challenger Lap & Shoulder Belt, Rear Outer Part Number: 6KE101R9AC

$85.43 MSRP: $127.00You Save: $41.57 (33%)Ships in 1-3 Business DaysDodge Challenger Seat Belt - Front Part Number: 1SG57XDVAK

$317.24 MSRP: $467.00You Save: $149.76 (33%)Ships in 1-2 Business DaysDodge Challenger Lap & Shoulder Belt, Front Part Number: 1SG581R5AK

$357.24 MSRP: $521.00You Save: $163.76 (32%)Ships in 1-2 Business DaysDodge Challenger Buckle End, Rear Inner Part Number: 1BY491X9AC

$85.60 MSRP: $127.00You Save: $41.40 (33%)Ships in 1-3 Business DaysDodge Challenger Lap & Shoulder Belt, Front Part Number: 1SG571R5AK

$368.69 MSRP: $538.00You Save: $169.31 (32%)Ships in 1-2 Business Days

Dodge Challenger Lap & Shoulder Belt, Front Driver Side Part Number: 1SG57XDVAD

$381.29 MSRP: $555.00You Save: $173.71 (32%)Dodge Challenger Buckle End, Front Inner Passenger Side Part Number: 1HZ101DVAF

$333.10 MSRP: $491.00You Save: $157.90 (33%)Dodge Challenger Lap & Shoulder Belt, Rear Outer Part Number: 5UZ231R5AC

$130.30 MSRP: $192.00You Save: $61.70 (33%)

| Page 1 of 3 |Next >

1-20 of 43 Results

Dodge Challenger Seat Belt

Choose OEM Seat Belt that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Seat Belt follows strict manufacturing steps to lock in quality and fit. If your Dodge Challenger matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Challenger parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Challenger Seat Belt Parts and Q&A

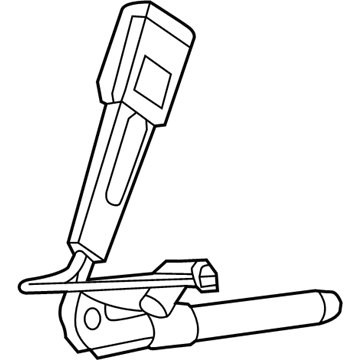

- Q: How to Replace a Damaged or Separated Seat Belt Molded Plastic Web Stop Button on Dodge Challenger?A:The latch plate will not move to the lower belt anchor when the seat belt is not in use, thanks to a molded plastic web stop button on the tip half of the seat belt. A damaged button or one that's no longer connected can be fixed using a special kit made up of two molded plastic button halves: one plastic spike and one with a hole. Buttons are only sold as full pairs. Using KD Tools #3358 or Snap-on #WWPR13A wheel weight pliers and Mopar Bond-All Gel #04467709 glue is necessary to do a wheel weights replacement. Check all seat belts, buckles, seats, straps and their mounting hardware for proper fixing and any damage, changing any with cuts or tears and make certain the latch plate and anchor plate are in good condition. If the previous button area cannot be located, position your new button 4 inches from the webbing's lower anchor point, then measure. Stuck the seat belt latch plate in its proper spot, above the web stop button, prior to fitting the new button. To the side closest to the center of the steering wheel, poke through the webbing with the male button spike so that the male button head points toward the inside of the vehicle. Place a little dab of adhesive around the middle of the back on the female button, then press it over the sticking-out spike coming from the webbing. Lower the flat jaw of the pliers onto the webbing spike, then press it into the webbing with the curved jaw, making sure the flattened area is now below the female button's edge. Don't forget to see if the web stop button has security protection as well.