JeepParts

My Garage

My Account

Cart

OEM Dodge Ram 2500 Van Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Brake Lines found

Dodge Ram 2500 Van Flex Hose Part Number: 52008296AB

$34.57 MSRP: $49.70You Save: $15.13 (31%)Ships in 1-3 Business DaysDodge Ram 2500 Van Flex Hose, Rear Part Number: 52009458AD

$63.16 MSRP: $92.95You Save: $29.79 (33%)Ships in 1-2 Business DaysDodge Ram 2500 Van Flex Hose, Rear Part Number: 52009458AF

Dodge Ram 2500 Van Flex Hose Part Number: 52009451AG

Dodge Ram 2500 Van Flex Hose Part Number: 52009450AG

Dodge Ram 2500 Van Flex Hose Part Number: 52009449AG

Dodge Ram 2500 Van Flex Hose Part Number: 52008509AC

Dodge Ram 2500 Van Brake Line

Choose OEM Brake Line that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Brake Line follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 2500 Van matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 2500 Van parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Ram 2500 Van Brake Line Parts and Q&A

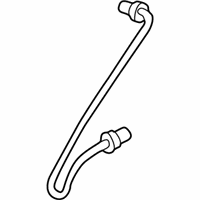

- Q: What are the recommended procedures and tools for Brake Line and hose service and repair on Dodge Ram 2500 Van?A:For brake tubes and lines, using a reformed metal tube is preferable and if factory items can't be found and emergency repair is needed, double-wall steel is acceptable. Bending brake tubes must be done with special equipment to stop twisting or kinking and an ISO flare or double inverted flare must be created with specialized flaring tools. The first step of double inverted flaring is to use a Tubing Cutter to cut the damaged part off and then gently ream the frayed area to secure a good flare. Slip a replacement tube nut on the tube, put the tube in the flaring tool and place the gauge form on the other end of the tube. Pass the tubing through the flaring tool jaws until it rests against the indentation in the gauge that fits your tube. Once positioned, tighten the tool with the bar until it is secure. Place the small end of the gauge into the long part of the tube, swing the compression disc towards the driver side over the gauge and put the tapered flaring screw into the center of the recessed area in the compression disc. Bring the tool handle to high tension, so the plug gauge is securely on the tool jaws for beginning the inverted flare. Remove the gauge and finish the inverted flare before releasing any tension. An ISO flare needs to be made with the Snap-On Flaring Tool TFM-428 or with an equivalent device. Take off the bad tube, fix any kinks inside the tube with a Tubing Cutter and put the tube nut in place. Place the tube in the flaring tool up against the top of the machine and tighten the tool bar around it. Insert and tighten the correct size adaptor onto the flaring tool yoke screw, rub a little lubricant on the adaptor, align it with the yoke screw, then turn the yoke screw until the adaptor is seated on the tool bar.