JeepParts

My Garage

My Account

Cart

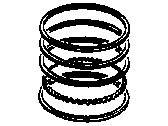

OEM Jeep Cherokee Piston Ring Set

Piston Ring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Piston Ring Sets found

Jeep Cherokee Piston Rings Part Number: 4762462

$183.09 MSRP: $232.10You Save: $49.01 (22%)Ships in 1-2 Business DaysJeep Cherokee Piston Rings Part Number: 4762461

$7.15 MSRP: $9.07You Save: $1.92 (22%)Ships in 1-2 Business Days

Jeep Cherokee Piston Ring Set Part Number: 68231951AB

Jeep Cherokee Piston Ring Set Part Number: 68214841AA

Jeep Cherokee Piston Rings, Lower Part Number: J1467681

Jeep Cherokee Piston Rings Part Number: 4798878

Jeep Cherokee Piston Rings Part Number: 4798324

Jeep Cherokee Piston Ring Set Part Number: 68400553AA

$179.01 MSRP: $267.00You Save: $87.99 (33%)Jeep Cherokee Piston Ring Set Part Number: 68450984AA

$117.92 MSRP: $177.00You Save: $59.08 (34%)Ships in 1-2 Business Days

Jeep Cherokee Piston Ring Set

Choose OEM Piston Ring Set that meet Jeep factory standards. Jeep designs and tests every component for precision and durability. Each Piston Ring Set follows strict manufacturing steps to lock in quality and fit. If your Jeep Cherokee matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Cherokee parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Jeep Cherokee Piston Ring Set Parts and Q&A

- Q: How to Service and Repair a Piston Ring Set on Jeep Cherokee?A:Start servicing the Piston ring by cleaning carbon out of the ring grooves to avoid removing too much metal which might modify ring-to-groove clearances and destroy the ring-to-land seating. It is important that the grooves where the piston rings sit are smooth and undamaged. To measure ring side clearance, place a feeler gauge tightly between the ring land and ring, making sure the ring rotates easily within the groove. For both top and second compression rings, acceptability ranges from 0.042 - 0.084 mm (0.0017 - 0.0033 inch) side clearance and for the oil control ring, it is between 0.06 - 0.21 mm (0.0024 - 0.0083 inch). Then put the ring into the cylinder and push it down with the inverted piston to the lower part of the ring travel. Check the gap between the ring ends using a feeler gauge. Ring gaps within the range of 0.229 - 0.610 mm (0.0090 - 0.0240 inch) are acceptable for the top compression ring, 0.483 - 0.965 mm (0.0190 - 0.0380 inch) for the second compression ring and 0.254 - 1.500 mm (0.010 - 0.060 inch) for the oil control ring. You can align the oil control rings so either side is up; first use the rail spacer, then place the side rails. The top compression ring is smooth and shiny; you can install it front or back. The second ring has a little cavity at its base, plus a dot above, for accurate installation. With the dot facing up, put the second compression ring in place using a ring installer, then add the top compression ring. Arrange the gaps on the piston so that: the oil spacer gap is on the centerline of the piston skirt, the two oil rail gaps are 180 degrees opposite on the piston pin bore's centerline, No. 2 compression ring is 180° from the top oil rail and No. 1 compression ring is 180° from No. 2.