JeepParts

My Garage

My Account

Cart

OEM Jeep Cherokee Speed Sensor

Speed Control Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Speed Sensors found

Jeep Cherokee Vehicle Speed Sensor Part Number: T0739789

$60.29 MSRP: $76.43You Save: $16.14 (22%)Ships in 1-2 Business DaysJeep Cherokee ABS Sensor Part Number: 68141898AD

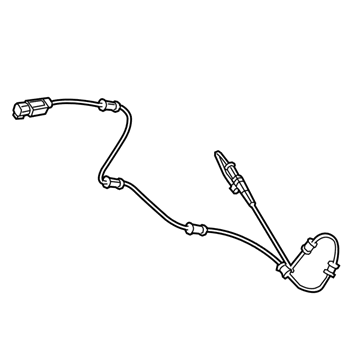

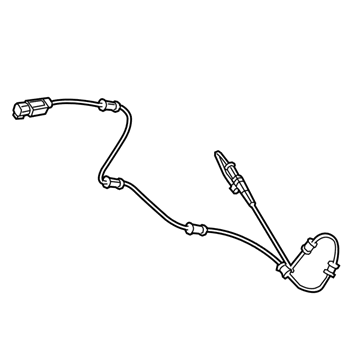

$21.76 MSRP: $37.60You Save: $15.84 (43%)Jeep Cherokee ABS Sensor, Front Part Number: 68141887AF

$55.86 MSRP: $83.50You Save: $27.64 (34%)Jeep Cherokee ABS Sensor, Rear Part Number: 4779897AC

$28.41 MSRP: $42.40You Save: $13.99 (33%)Ships in 1-2 Business DaysJeep Cherokee ABS Sensor, Rear Part Number: 68291947AC

$19.18 MSRP: $28.45You Save: $9.27 (33%)Ships in 1-2 Business DaysJeep Cherokee ABS Sensor, Rear Part Number: 68291949AC

$18.78 MSRP: $27.75You Save: $8.97 (33%)Ships in 1-2 Business DaysJeep Cherokee ABS Sensor, Front Part Number: 68570196AB

$21.03 MSRP: $28.50You Save: $7.47 (27%)Ships in 1-2 Business Days

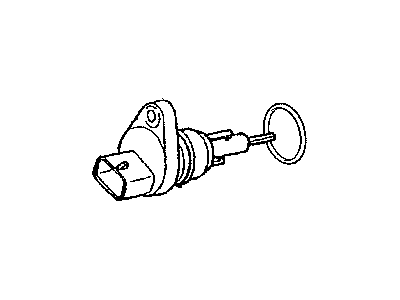

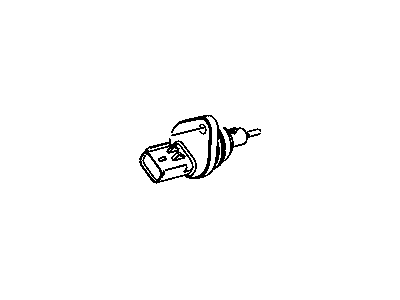

Jeep Cherokee Vehicle Speed Sensor Part Number: 56028183

Jeep Cherokee Vehicle Speed Sensor Part Number: 56027905

Jeep Cherokee Vehicle Speed Sensor Part Number: 33004761

Jeep Cherokee Rear Speed Sensor Part Number: 68141898AC

$28.83 MSRP: $41.70You Save: $12.87 (31%)

Jeep Cherokee ABS Sensor, Rear Part Number: 4779897AB

$29.29 MSRP: $42.40You Save: $13.11 (31%)Jeep Cherokee ABS Sensor Part Number: 56005217AB

Jeep Cherokee ABS Sensor Part Number: 52005933AB

Jeep Cherokee ABS Sensor Part Number: 52005932AB

Jeep Cherokee Speed Sensor

Choose OEM Speed Sensor that meet Jeep factory standards. Jeep designs and tests every component for precision and durability. Each Speed Sensor follows strict manufacturing steps to lock in quality and fit. If your Jeep Cherokee matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Cherokee parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

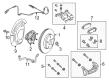

Jeep Cherokee car assembly has a component called the Speed Sensor which is essential in reading speed of the car as well as the rotational speed of the wheels. These figures are crucial to the vehicular's computer circuits of controlling and reconfiguring several parts of the vehicle such as the engine and the Anti-locking Brake System (ABS). Jeep Cherokee models are equipped with both, a vehicle speed sensor (VSS) and a wheel speed sensor (WSS) and the latter is essential to superior systems such as the ABS. The Speed Sensors used in Jeep Cherokee over the years have been classified into two depending on how they operate and these are, passive and active sensors. Passive sensors themselves create signal from magnetic interferences produced by rotating components of the machine while active sensors add signal conditioning to the output from the passive sensors. Innovations concerning these sensors have improved, in regard to reliability and especially as far as accuracy is concerned, therefore the Jeep Cherokee can perform better regardless of changing driving conditions.

Jeep Cherokee Speed Sensor Parts and Q&A

- Q: How to Service and Repair a Speed Sensor on the Rear Wheel on Jeep Cherokee?A:Start by lifting and moving the rear seat forward and at the end of its panel, unplug the speed sensor by disconnecting it. Move the sensor grommets and their wiring under the floorpan and raise the vehicle off the ground. Remove the sensor wires from the rear axle connectors, unbolt and remove the wheel and tire assembly and take away the Brake Drum. With clip pliers, release the clips binding the sensor wires to the Brake Lines, rear axle and brake hose and pull the support plate grommet. Remove the bolt holding the sensor to the bracket and then remove the sensor. When using an original sensor, first remove any cardboard spacer bits left on the sensor pickup face with a dry shop towel. Push the sensor cable through the hole in the plate and seat the grommet for the sensor in that plate. If the original bolt appears worn or damaged, use Mopar Lock N' Seal or Loctite 242 and a new bolt. After that, position and install the sensor bolt finger tight. If the previous rear sensor is installed, place a feeler gauge between the sensor and housing to measure an air gap of 0.92 - 1.275 mm (0.036 - 0.05 inch) and tighten the sensor bolt to 13 Nm (115 inch lbs.). If you connect a new sensor, hold the cardboard spacer to the sensor face and tighten the bolt to 13 Nm (115 inch lbs.). This will let the correct gap form as the tone ring spins and removes the spacer from the sensor's face. Move the wires to the back of the car, send them through the hole in the floorpan and seal them with the sensor grommets. Clip the wires for the rear sensor to the brake hose and axle and confirm that the wire is not in contact with any rotating part. After that, mount the brake drum and wheel and tire, set the car down, link the sensor wire to the harness connector and lay out the carpet before collapsing the rear seat.

- Q: How to Maintain a Speed Sensor on Jeep Cherokee?A:You should start by placing the Wheel Speed Sensor, by jacking up the vehicle and moving the steering wheel sideways. Take out the sensor wire from the mounting brackets, wipe the sensor with a shop towel and then proceed. Pull the bolt that holds the sensor to the Steering Knuckle and extract the sensor. Then, disconnect the sensor wire from the mountings on the body and steering knuckle and pop the grommet covering the sensor wire free from the wheel house panel. Within the engine compartment, cut off the attachment where the sensor is found on the harness plug and pull off the sensor and the wire. Reusing the previous sensor. First, take away any spacer material left on the sensor's face by wiping it dry with a shop towel. Secure the sensor in the steering knuckle by adding special fluid such as Mopar Lock N' Seal or Loctite - 242 onto the bolt and using a new sensor bolt if the original is not in good condition. Placement of the sensor should be at the steering knuckle with the locating tab fitting into the hole and install the sensor attaching bolt finger tight before tightening it to 4.7 Nm (42 in-lbs). Each time you reuse an original sensor, check the air gap which should measure from 0.36 to 1.5 mm (0.014 to 0.059 inch). Attach the wire's end to the spring seat bracket and cover the connection with grommets, then pull the wire forward and beneath the Shock Absorber and secure its other end to the steering knuckle and body bracket. Direct the sensor wire toward the outer sill bracket and check for no twists as you secure it there with the grommet. Check that the sensor wire goes forward above the sill bracket, loops below the bracket towards the Brake Line and that the loose end is pointed down. After that, push the sensor wire grommet into the body panel and hold the wire to the brake line at its location before connecting the sensor wire to the harness found in the engine compartment.