JeepParts

My Garage

My Account

Cart

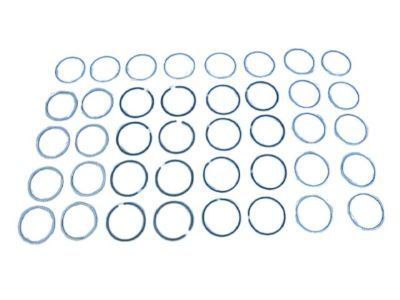

OEM Jeep Commander Piston Ring Set

Piston Ring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Piston Ring Sets found

Jeep Commander Piston Rings Part Number: 68031606AA

$44.45 MSRP: $66.45You Save: $22.00 (34%)Ships in 1-2 Business Days

Jeep Commander Piston Rings Part Number: 5086002AC

$49.89 MSRP: $63.25You Save: $13.36 (22%)Ships in 1-2 Business Days

Jeep Commander Piston Rings Part Number: 5012364AE

Jeep Commander Piston Rings Part Number: 68046210AB

$241.33 MSRP: $359.00You Save: $117.67 (33%)

Jeep Commander Piston Ring Set

Choose OEM Piston Ring Set that meet Jeep factory standards. Jeep designs and tests every component for precision and durability. Each Piston Ring Set follows strict manufacturing steps to lock in quality and fit. If your Jeep Commander matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Commander parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

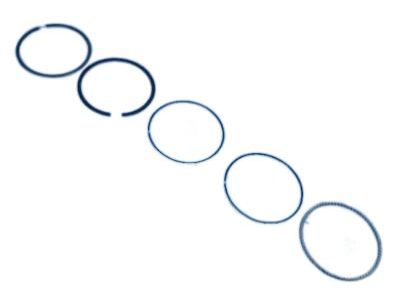

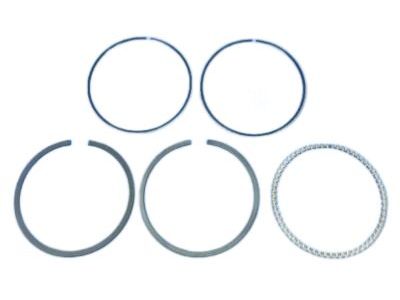

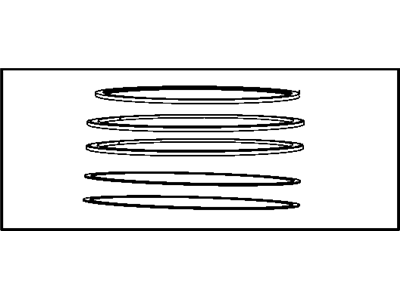

The practical operation of Jeep Commander vehicles depends on the well-known piston ring set from Jeep Commander which demonstrates exceptional reliability and performance. The piston ring set ensures perfect combustion chamber sealing while it burns fuel-air mixtures optimally and blocks gas leakage to promote safety and engine efficiency. The Piston Ring Set works with different Jeep Commander models through advanced technology that uses thinner rings for better oil control and sealing performance. The standard packaging of Jeep Commander pistons includes three ductile iron or steel rings: two compression rings and one oil control ring which frequently receive heat-resistant coatings. The innovative technological development of Jeep Commander Piston Ring Sets produced various shaped components and applied coatings that serve to boost both performance quality and durability thereby establishing the product as an industry-leading solution. Engine efficiency and reduced operational friction work in tandem to enhance both performance and safety of Jeep Commander vehicles through the car Piston Ring Set. The car Piston Ring Set continues to be a fundamental element which ensures the manufacturer car vehicles deliver the expected reliability and power performance to their drivers while the brand develops its model product range. The car Piston Ring Set maintains its perfect reputation in the automaker world through consistent pursuit of quality and performance excellence.

Jeep Commander Piston Ring Set Parts and Q&A

- Q: How to Check Clearances and Install a Piston Ring Set Before Reinstallation on Jeep Commander?A:Always clean the cylinder bore, put in the ring and measure the gap at the part of the ring where it is at least 12 mm (0.50 inches) above the bottom of the bore. Place the ring inside the cylinder by pushing it down with a Piston, checking that it is squared before measuring the end gap with a feeler gauge and changing any ring with a gap that is not right. Always check the grooves for piston rings, making sure they are clean and nicks are removed before measuring, inserting a feeler gauge and replacing the ones that are out of specification. Turn the ring as it sits on the piston to check it does not jam and remember that the manufacturer's Dot should face the top of the piston when installing the No. 2 ring. Place the oil ring expander on top, followed by the upper oil ring side rail by sliding one end into the expander ring and the piston's groove, squeezing it down into position. Then, do the same for the lower side rail as well. Install the No. 2 intermediate piston ring and the No. 1 upper piston ring using a piston ring installer, with all end gaps in correct position, the expander ring gap at least 45° from the side rail gaps and not in the thrust direction or on the piston pin center.