JeepParts

My Garage

My Account

Cart

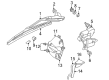

OEM 2000 Dodge Durango Wiper Motor

Windshield Wiper Motor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Wiper Motors found

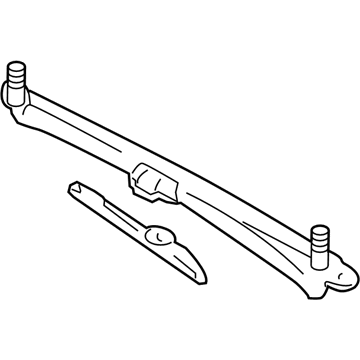

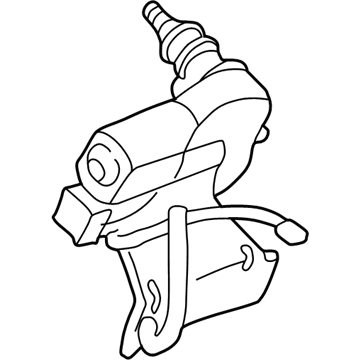

2000 Dodge Durango Wiper Motor Part Number: 55154863AI

Product Specifications- Other Name: Pivot - Windshield Wiper; Windshield Wiper Motor; Motor & Linkage; Front Motor; Motor And Linkage Windshield Wiper

- Replaces: 55154863AC, 55154863AE, 55154863AH, 55154863AG, 55154863AF, 55154863AD

- Item Weight: 7.50 Pounds

- Item Dimensions: 30.2 x 6.2 x 5.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 55154863AI

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

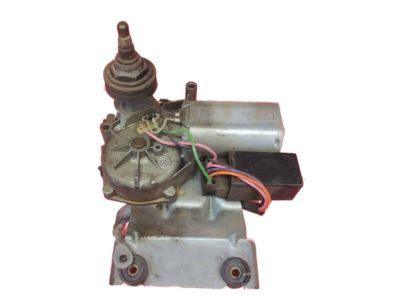

2000 Dodge Durango Wiper Motor Part Number: 55076648

Product Specifications- Other Name: Motor - Windshield Wiper; Back Glass Wiper Motor; Rear Motor; Motor Windshield Wiper

- Item Weight: 4.00 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 55076648

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Dodge Durango Wiper Motor Parts and Q&A

- Q: How to Maintain a Wiper Motor on 2000 Dodge Durango?A: Start the wiper motor service by isolating the battery's negative cable. The front wiper motor can be accessed after you take the wiper arms off the wiper pivots and carefully take out the weather strip along the front of the cowl plenum cover/grille panel and the panel itself. Then, remove all four plastic nuts between the top cowl plenum panel and the grille cover, together with the plastic rivets and two push-in retainers at the front and rear corners. Release the slotted center holes from the adhesive fasteners on both sides, separate the cowl plenum cover/grille panel enough to get to the washer nozzle and vacuum plumbing and unhook the washer supply hose. Yank the vacuum supply hose from the reservoir on the cowl plenum cover/grille panel fastened to the right end and then get rid of the cowl from the vehicle. To work on the wiper module, first loosen the four screws holding it to the cowl plenum panel, so you can reach the wire harness connector, unplug it and remove the module. Once again, follow the installation steps, connecting the nozzle hoses and tightening them to 8 Nm (72 in. lbs.) Rear wiper motor work requires you to disconnect and remove the negative battery cable and then take out the rear wiper arm from the rear wiper motor shaft. Pry at the base of the nut cover with a special removal tool, wait for it to come unglued and slot the output shaft nut out of the outer liftgate. Martin, BMW G90 Trim, 2016 F10, rear wiper motor Rear, Martini, BMW G90, F10, C-Paintcode, Frost4, Frost4. Pull out the rear wiper motor and its bracket, then at reinstallation, line up the motor and bracket on the inside of the liftgate and insert only the loose mounting screws. Place the wiper motor output shaft through the mounting hole in the liftgate panel and hold it with the retaining nut (torque is 4.8 Nm or 43 in. lbs.). After this, reverse all the removal steps, secure the bracket to the motor using the screws and tighten them to 8.1 Nm (72 in. lbs.).