JeepParts

My Garage

My Account

Cart

OEM 2001 Dodge Dakota A/C Clutch

Air Conditioning Clutch- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 A/C Clutches found

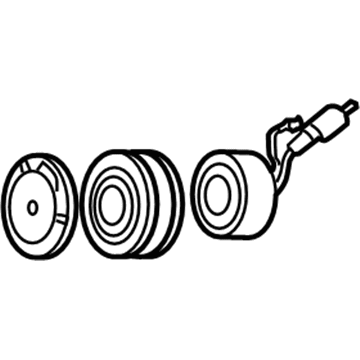

2001 Dodge Dakota Clutch & Pulley Part Number: 5015314AA

Product Specifications- Other Name: Clutch - A/C Compressor; A/C Compressor Clutch; Clutch; Clutch A/C Compressor

- Item Weight: 4.90 Pounds

- Item Dimensions: 6.6 x 6.6 x 2.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5015314AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2001 Dodge Dakota Clutch & Pulley Part Number: 4882008

Product Specifications- Other Name: Clutch - A/C Compressor; A/C Compressor Clutch; Clutch Coil; Clutch; Clutch A/C Compressor

- Item Weight: 6.00 Pounds

- Item Dimensions: 6.8 x 6.6 x 2.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4882008

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2001 Dodge Dakota Clutch & Pulley Part Number: 5016126AA

Product Specifications- Other Name: Clutch - A/C Compressor; A/C Compressor Clutch; Clutch; Compressor; Clutch A/C Compressor

- Item Weight: 6.50 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5016126AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2001 Dodge Dakota A/C Clutch Parts and Q&A

- Q: How to Replace the A/C Clutch on 2001 Dodge Dakota?A: Before handling the A/C compressor clutch, first disconnect the car battery's negative terminal and then remove the serpentine drive belt. Disconnect the compressor clutch coil wire harness from your car. Apply Special Tool 6462 from Kit 6460, push its two pins into the clutch plate holes and then turn that tool while holding the plate for support until the hex nut can be removed. Then, pull out the clutch plate and shims and use snap ring pliers to remove the outside housing snap ring. Insert the end of the rotor puller (C-6141-1 Special Tool) into the tool holder and place the shaft protector (C-6141-2 Special Tool in the holder.) Use Special Tool C-6461 to tighten the through-bolts on the puller flange into the rotor puller jaws and then turn the puller center bolt clockwise until the rotor pulley comes loose. Pull the screw and the retainer out of the clutch coil lead wire harness by the compressor front housing, then open the clutch field coil snap ring and take it off. First, put in the clutch field coil and snap ring, then clip the clutch coil lead wire harness retaining clip to the compressor front housing and tighten the screw. With the rotor assembly square on the front compressor housing hub, thread the Special Tool 6464 into Special Tool 6143 from Kit 6460 and place the driver assembly into the rotor's bearing cavity so outer edge of the driver tool sits firmly on the inner race of the rotor bearing. While guiding the rotor, gently hit the end of the driver as it makes contact with the compressor front housing hub to be sure it is installed properly and you hear the sound shift. Place the front rotor snap ring so that the bevel is oriented outward and makes sure it is lodged correctly so as not to cause clutch failure. Next, attach the original clutch shims to the compressor shaft, put down the clutch plate using Special Tool 6141-2 and tap until it hits the shims, listening for a difference in sound. Insert the compressor shaft hex nut and tighten it to a torque of 14.4 Nm (10.5 ft. lbs.). Next, measure the clutch air gap with a feeler gauge; if it is outside the range of 0.41 to 0.79 millimeters (0.016 to 0.031 inches), add or remove shims to equalize it around the clutch by lightly prying or tapping. When putting in a new clutch, add the thinest (0.13 millimeter/0.005 inch) shim plus a 0.50 millimeter (0.020 inch) shim from the clutch pack, since the former clutch was not installed.