JeepParts

My Garage

My Account

Cart

OEM 2002 Chrysler PT Cruiser Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Brake Calipers found

2002 Chrysler PT Cruiser Caliper, Rear Driver Side Part Number: 5083159AA

$125.17 MSRP: $227.00You Save: $101.83 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Left; Caliper Disc Brake; Brake Caliper

- Position: Rear Driver Side

- Item Weight: 4.00 Pounds

- Item Dimensions: 8.4 x 6.7 x 3.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5083159AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

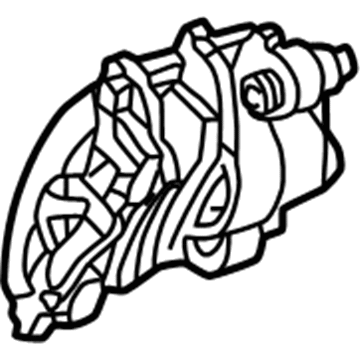

2002 Chrysler PT Cruiser Caliper, Front Driver Side Part Number: 5017833AA

$132.55 MSRP: $211.00You Save: $78.45 (38%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Left; Caliper Disc Brake; Brake Caliper

- Position: Front Driver Side

- Item Weight: 7.90 Pounds

- Item Dimensions: 8.0 x 7.8 x 6.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5017833AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

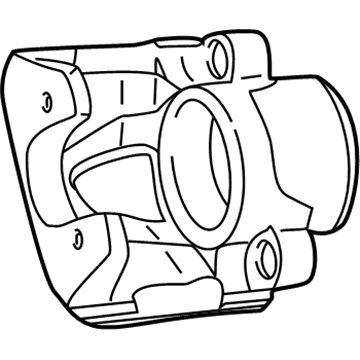

2002 Chrysler PT Cruiser Caliper, Front Passenger Side Part Number: 5017832AA

$154.82 MSRP: $229.00You Save: $74.18 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Right; Caliper Disc Brake; Brake Caliper

- Position: Front Passenger Side

- Item Weight: 7.90 Pounds

- Item Dimensions: 8.8 x 8.3 x 5.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5017832AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

- Product Specifications

- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Right; Caliper Disc Brake; Brake Caliper

- Position: Rear Passenger Side

- Item Weight: 4.10 Pounds

- Item Dimensions: 8.5 x 6.6 x 3.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5083158AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Chrysler PT Cruiser Brake Caliper Parts and Q&A

- Q: How to Maintain and Fix a Brake Caliper on 2002 Chrysler PT Cruiser?A: Begin by attaching a brake pedal holding tool to the vehicle that prevents you from depressing the brake system beyond the first inch of pedal travel. Lift the car and take the front tire and wheel off. Cut the banjo bolt from the brake hose going to the brake caliper and let go of the two washers it holds. Loosen the two guide pin bolts of the brake caliper and take it off the disc brake adapter. Before beginning the disassembly, clean and examine the caliper, making sure not to blow away the piston with a jet of air, since this is risky for your safety. Attach the caliper in a vise with guards set up so there is a wooden block inside. As required, blast short spritzes of low-pressure air into the brake caliper inlet to force the piston out, then be sure to remove the old dust boot. Extract the seal from the groove with a soft tool, discard the old seal, then use alcohol or a suitable solvent to clean the piston bore and drilled passageways and dry the passages with a clean cloth. Look for scratches or pitting on the piston and around the bore; you can clear light damage with crocus cloth. Spray the brake parts with water, using a misting bottle, then clean them with a damp microfiber cloth. Discard the cloth in an appropriately sealed and labeled container as directed by OSHA and EPA. To wash or flush the brake caliper's internal pathways, spray fresh brake fluid or Mopar Non-Chlorinated Brake Parts Cleaner into it. Do not use gasoline, kerosene, alcohol, oil or fluids that contain mineral oil. Look over the caliper to check for brake fluid leaks and any damage to the piston dust boot; if it doesn't pass your inspection, pull it apart and clean it, changing the worn seals and dust boots. During installation, put DOT 3 brake fluid and a new seal in the special reservoir and dip them in fluid before placing the seal in the caliper bore hole. Coat the piston and dust boot with brake fluid and put the boot over the piston so the seal is guided into its groove. Evenly push against the piston as you seat it to meet the cartridge, stopping when the dust boot seal rests in the groove on the cartridge or ammo can. Attach the caliper to the car, checking that the piston is fully retracted using a C-clamp and a wood block to do this safely. Put the caliper over the brake shoes, align the guide pin bolt holes and then tighten the guide pin bolts to 35 Nm (26 ft. lbs.). Replace the banjo bolt with new washers and fasten it to 26 Nm (230 in. lbs. or 19 ft. lbs.), after that, put the tire and wheel back on, tightening the wheel nuts to 135 Nm (100 ft. lbs.). Set the car to its lowest position, remove the tool supporting the brake pedal, bleed any necessary calipers and use a road test to verify if the brake shoes are seated and working correctly.