JeepParts

My Garage

My Account

Cart

OEM 2002 Dodge Dakota Intake Manifold

Engine Intake Manifold- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Intake Manifolds found

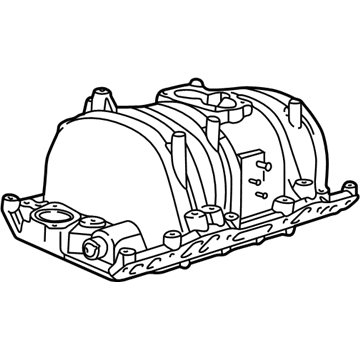

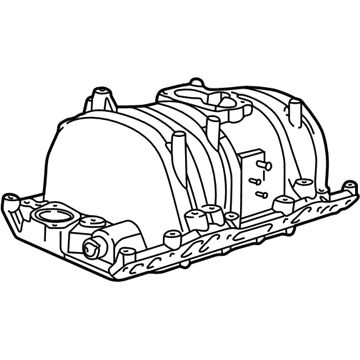

2002 Dodge Dakota Intake Manifold Part Number: 53010315AG

Product Specifications- Other Name: Manifold - Intake; Engine Intake Manifold; Manifold Intake

- Item Weight: 12.40 Pounds

- Item Dimensions: 20.5 x 13.2 x 12.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53010315AG

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Dodge Dakota Intake Manifold Part Number: 4897489AB

Product Specifications- Other Name: Manifold - Intake; Engine Intake Manifold; Manifold Intake

- Item Weight: 3.20 Pounds

- Item Dimensions: 18.2 x 18.2 x 10.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4897489AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

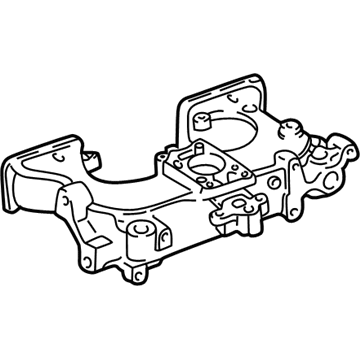

2002 Dodge Dakota Intake Manifold Part Number: 53010245

Product Specifications- Other Name: Manifold - Intake; Engine Intake Manifold; Manifold, Intake; Manifold Intake

- Item Weight: 7.50 Pounds

- Item Dimensions: 14.2 x 11.1 x 7.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53010245

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Dodge Dakota Intake Manifold Part Number: 4897490AC

Product Specifications- Other Name: Manifold - Intake; Engine Intake Manifold; Manifold Intake

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4897490AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Dodge Dakota Intake Manifold Parts and Q&A

- Q: How to Remove and Reinstall an Intake Manifold on 2002 Dodge Dakota?A: Before removing the intake manifold, take the negative cable from the battery and drain the cooling liquid. After that, get rid of the A/C compressor, generator, accessory drive bracket and air cleaner. Pull the fuel pump relay, hold the key in the key position for at least six seconds, then disconnect the fuel lines. If the car is equipped, take out the accelerator linkage, speed control and transmission kickdown cables and afterward, take out the return spring. Take the distributor cap and all the wires from it, then unplug the coil wires, heat indicator sending unit wire and both heater hoses. Take off the closed crankcase ventilation and evaporation control systems and after that remove the intake manifold bolts. Lift everything out at once: the intake manifold and throttle body, get rid of the side intake manifold gaskets and the front and rear cross-over gaskets. If these parts are dirty, you may need to remove the throttle body and plenum pan and get rid of the gasket. Rinse the manifold with solvent and dry it with compressed air, making certain the front and rear gasket surfaces on the cylinder block are cleaned and dry. Look over the manifold for breaks and use a straightedge to see if the mating surfaces are flat. If the plenum pan is taken off, slot a fresh gasket in, attach the pan and fasten each bolt to 5.4 Nm, then to 9.5 Nm, then make sure they are tightened to 9.5 Nm again. Fit the flange gaskets correctly so they match the cylinder head tabs and add Mopar GEN II Silicone Rubber Adhesive Sealant on each corner joint. Place the front and rear cross-over gaskets and then add a brand new gasket to join the intake manifold with the throttle body. Slowly place the intake manifold into position on the cylinder block, then make sure all seals are in place as you move it. After installing the intake manifold bolts, tighten bolts 1 and 2 to 8 Nm and bolts 3 through 12 to the same. Check all bolts are secure to 8 Nm before going on to tighten all of the bolts simultaneously to 16 Nm and checking again. Connect the ventilation and evaporation control systems, join the coil wires, hook up the heat indicator sending unit wire, heat hoses and bypass hose. You should install the distributor cap and wires, hook up the return spring, then attach the accelerator linkage, speed control and transmission kickdown cables, before installing the fuel lines. Once you have finished, mount the accessory drive bracket, A/C compressor, put in the generator, fit the drive belt, add air cleaner, top off the cooling system and link back the negative cable to the battery.