JeepParts

My Garage

My Account

Cart

OEM 2002 Jeep Liberty Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Crankshafts found

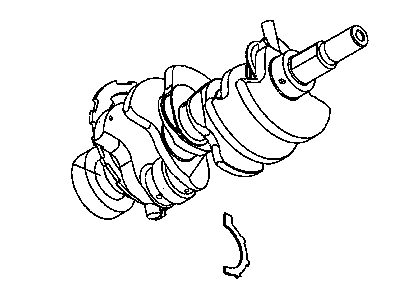

2002 Jeep Liberty Crankshaft Part Number: 53020959

$468.10 MSRP: $593.40You Save: $125.30 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft

- Item Weight: 46.50 Pounds

- Item Dimensions: 28.4 x 10.2 x 8.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53020959

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

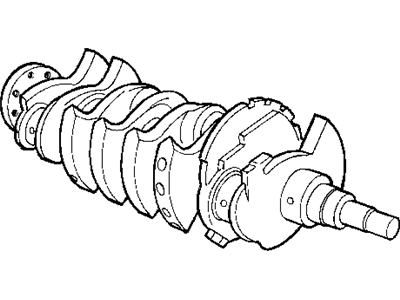

2002 Jeep Liberty Crankshaft Part Number: 4621917

Product Specifications- Other Name: Crankshft; Crankshaft, Machined

- Item Weight: 50.80 Pounds

- Item Dimensions: 23.3 x 8.8 x 8.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4621917

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Jeep Liberty Crankshaft Parts and Q&A

- Q: How to Remove and Replace a Crankshaft on 2002 Jeep Liberty?A: You must remove the engine, the flex plate and the back seal on the crankshaft before you can remove and replace the crankshaft. After that, set up the engine on a repair stand and remove the oil and oil filter. After that, you should remove the oil pan, timing belt covers, timing belt, oil pump and balance shafts with housing assembly. All bolts securing the engine block to the bedplate have to be removed and the bedplate should be yanked loose only after the dowel pins are hit gently with a mallet. As long as care is taken, the crankshaft can be taken out of the block to access the main bearings and journals. It is important to check if the crankshaft journals show excessive wear, taper or scoring and if grinding them doesn't surpass 0.305 mm (0.012 in.) below the standard diameter and the thrust faces of the No. 3 main bearing remain ungrinded. Rough edges from the drilled oil holes should be filed down after grinding and the final polish of nodular cast iron crankshafts should be done in the direction the crankshaft normally turns. The main bearing shells should be placed into the cylinder block and the groove for lubrication should face toward the engine, so oil holes and bearing tabs are properly seated. Precaution should be given to prevent oil on the bedplate mating areas. Oil the bearings and journals before setting the crankshaft and use just the recommended anaerobic sealant on the bedplate. Apply a bead of Mopar Bed Plate Sealant around the cylinder block and afterward install the lower main bearings into the main bearing cap/bedplate so that they are properly seated. The main bedplate bolts should be fastened only by finger pressure before they are tightened. For correct alignment, rotate the crankshaft until the number 4 piston reaches TDC and move it rearward and forward to its limits, then wedge in place before tightening all bolts in sequence to 41 Nm (30 ft. lbs.). Once you've removed the wedge, make sure both pass-through bolts are tightened to 41 Nm (30 ft. lbs.) plus 1/4 turn and each of the other bolts to 28 Nm (20 ft. lbs.). Make sure the turning torque of the crankshaft does not go beyond 5.6 Nm or 50 in. lbs. The engine bolts should be assembled with Mopar Lock & Seal Adhesive. After applying it to the bolt threads, torque the flex plate to 95 Nm (70 ft. lbs.). Next, reinstall the engine.