JeepParts

My Garage

My Account

Cart

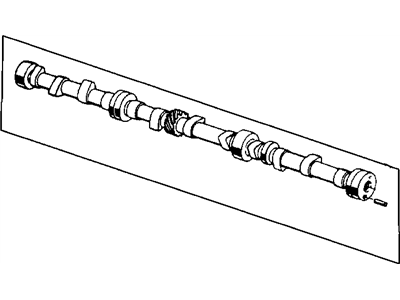

OEM 2002 Jeep Wrangler Camshaft

Cam- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Camshaft found

2002 Jeep Wrangler Camshaft Part Number: 53010448AA

Product Specifications- Item Weight: 13.30 Pounds

- Item Dimensions: 33.1 x 12.7 x 2.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53010448AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2002 Jeep Wrangler Camshaft Parts and Q&A

- Q: What Tools Are Needed to Replace a Camshaft on 2002 Jeep Wrangler?A: This camshaft is driven through four pressed-in, bearings in the cylinder block (babbitt-lined and steel-sleeved) and line reamed bearing bores and diameters are stepped down 0.254 mm (0.010 inch) at a time towards the rearmost bearing, to provide easier removal and assembly. The camshaft bearings are pressure lubed, and they should not be replaced without special removing and installing equipment e.g. tool 8544 Camshaft Bushing Remover Installer. Engine replacement demands stripping the engine, mainly removal. Start off by taking out the camshaft and then take out the camshaft bearings by the use of special tool 8544 or anything similar to this. After deflating the hot and pressurized coolant, then remove the drain cock, cap and the drain plugs. Remove the negative cable of the battery and pour the contents of the cooling system into a relative clean container and reuse in case the solution is clear. Take off the radiator or radiator, condenser on A/C equipped cars and cut marks into the distributor housing and cylinder block to line them up later. Take out the distributor and ignition leads, air inlet hose and resonator, engine cylinder head cover, the rocker arms, bridges, pivots, push rods, hydraulic valve tappets, vibration damper and timing case cover, the timing chain and sprockets before taking out the camshaft. Look at the journals of the camshaft bearing, lobes, distributor gear and also thrust plate, wear should be checked, the outside diameter of the number 1 bearing should be clean and needs to be well installed with aligning the oil hole to that of the oil gallery. Install new camshaft bearings and lubricate the camshaft with Mopar engine oil supplement or equivalent and then install carefully so as not to damage the bearings using tool 8544 or equivalent. Apply a lock on the tensioner block by turning the tensioner lever into the unlocked position and then compressing the spring with it by use of a pull. Installing the timing chain and sprockets, tensioner of the timing chain is released and a timing case cover with a new oil seal is installed. Refit vibration damper, hydraulic valve tappets, push rods, rocker arms, bridges, pivots and engine cylinder head cover. Connect the distributor and ignition wires, resonator assembly and the air inlet hose, tighten clamps to 4 Nm (35 inch lbs.), the radiator or radiator and condenser in case of installing an A/C connection.