JeepParts

My Garage

My Account

Cart

OEM 2003 Dodge Neon A/C Clutch

Air Conditioning Clutch- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 A/C Clutches found

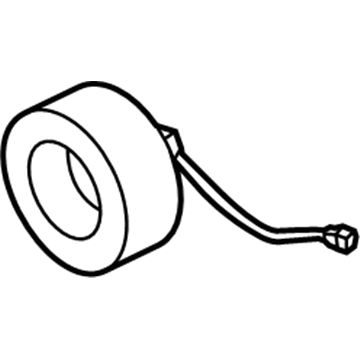

2003 Dodge Neon Clutch Coil Part Number: 5003681AA

$186.95 MSRP: $279.00You Save: $92.05 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil - A/C Clutch; A/C Compressor Clutch Coil; Clutch; Coil; Coil A/C Clutch; A/C Compressor Clutch

- Replaces: 5072863AA

- Item Weight: 2.10 Pounds

- Item Dimensions: 5.1 x 4.7 x 2.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5003681AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

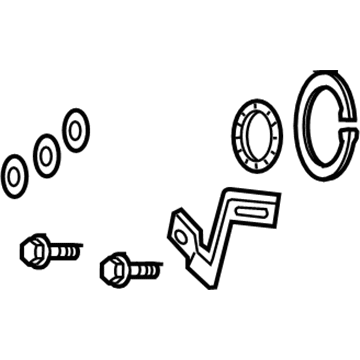

2003 Dodge Neon Repair Kit Part Number: 5014572AA

$18.19 MSRP: $32.95You Save: $14.76 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Clutch - A/C Compressor; Shaft Seals; Overhaul Kit; Clutch Overhaul Kit A/C Compressor

- Item Weight: 1.30 Pounds

- Item Dimensions: 2.9 x 2.6 x 0.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5014572AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

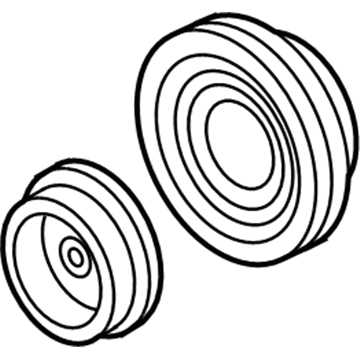

2003 Dodge Neon Clutch & Pulley Part Number: 5014573AA

Product Specifications- Other Name: Pulley Kit - A/C Compressor; A/C Compressor Clutch; Clutch; Pulley; Pulley Hub Kit A/C Compressor

- Item Weight: 3.80 Pounds

- Item Dimensions: 7.7 x 6.6 x 3.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5014573AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

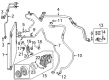

2003 Dodge Neon A/C Clutch Parts and Q&A

- Q: How to Service and Repair an A/C Clutch on 2003 Dodge Neon?A: When servicing the A/C compressor clutch, you should first take out the assembly, without letting the refrigerant release. First, remove the bolt from the compressor shaft by putting the band type oil filter remover on the clutch plate. Hit the clutch plate with a plastic hammer to remove it and any shim(s) you have inserted, but make certain you do not lose them. Don't insert screwdrivers where the clutch plate assembly meets the pulley to prevent from ruining anything. With Snap Ring Pliers, take out the pulley retaining snap ring and pull the pulley assembly off the compressor next. Unscrew the screw holding the coil wire bracket/ground clip and wire harness, then remove the snap ring that is holding the field coil inside the compressor and slide it off. See if the clutch pulley and front plate have worn badly or have any damage. If so, replace them. If you find oil on the friction surfaces, check the nose of the shaft for more oil; when felt is encountered in the front cover, exchange the seal if the felt is soaked. Look for patches of grease on the second bearing and change it as required. When installing, put the pin from the field coil through the small hole in the compressor end housing, secure the coil, route all of the lead wires correctly and fasten the coil wire bracket/screw. With a new snap ring, the bevel should face out, use Snap Ring Pliers to securely fit it and ensure it's in place to stop clutch failure. Assemble the pulley to the compressor, striking it with a bit of wood if necessary, then hold the retaining snap ring (bevel facing out) to ensure it is firmly in place. If you use the old front plate and pulley, it's fine to reuse the shims; otherwise, install a 2.54 mm (0.10 in.) shim stack at the shoulder. When you install a front plate or pulley assembly, measure the movement between these parts after turning on the engine with a dial indicator. You should see a gap of between 0.35 and 0.65 mm (0.014 - 0.026 inches). Afterward, set the compressor shaft bolt and tighten it to 17.5 ± 2 Nm (155 ± 20 in. lbs). Check the air gap in several locations and rotate the pulley by hand to check it rolls freely. After fitting a new clutch, run the A/C clutch 20 times, five seconds on, five seconds off, at A/C mode, 1500 - 2000 rpm engine speed and high blower speed to seat the clutch surface and improve its torque.