JeepParts

My Garage

My Account

Cart

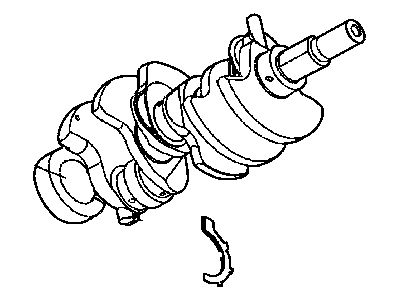

OEM 2004 Dodge Dakota Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Crankshaft found

2004 Dodge Dakota Crankshaft Part Number: 53020959AB

$629.85 MSRP: $959.00You Save: $329.15 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft; Crankshaft See Note

- Item Weight: 48.20 Pounds

- Item Dimensions: 28.4 x 10.1 x 8.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53020959AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2004 Dodge Dakota Crankshaft Parts and Q&A

- Q: How to Remove and Reinstall a Crankshaft from an Engine on 2004 Dodge Dakota?A: Before you can remove the crankshaft, you have to take out the engine from the vehicle and the engine oil pump. Do not force the oil pan gasket since it is attached to the block in three places and will stay in place when the pan is taken off. Remove next the bolts that hold the bedplate in place by noting the stud bolt positions for later installation. After that, remove the connecting rods, careful not to hurt the sealing area between the bedplate and cylinder block while doing so. Since the lower main bearing halves are part of the bedplate, be careful not to drop or damage them, as installing them incorrectly can badly damage the crankshaft. Following the instructions for using the pry points, carefully remove the bedplate, crankshaft and crankshaft tone wheel. Look at the bearing bores on the connecting rod and the main to see if there is any evidence of scoring, blue marks or major scratches. If present, some disassembly might be needed. Should there be cracks in the connecting rod bearing, the cylinder head is removed to examine and replace the piston and rod, but an engine replacement is required when there is damage to the bedplate or cylinder block main bearing bores. Should it be required, remove the main bearing halves from the cylinder block and bedplate, clean both sealing areas and the main bores and make sure the bedplate bearings are free from cracks or scoring. Examine the thrust washers for any signs of wear and split or crack the oil pan gasket/windage tray. Be sure to install the main bearings loosely when putting in the crankshaft and avoid damage to their surfaces. Place sealant on the tone wheel retaining screws first, coat the inner halves of the upper main bearing with clean oil before inserting them and finally screw the crankshaft tone wheel into place, tightening the screws to the approved torque of 15 Nm (11 ft. lbs.) Place the crankshaft in its area within the cylinder block, insert the thrust washing and apply leopard Engine RTV sealant around the bedplate to cylinder block area to stop oil leaks. Confirm the surfaces you're joining are clean and visible of any flaws and then install a 2.5 mm (0.100 inch) bead of Mopar Engine RTV sealant around the mating area. Lightly oil the crankshaft main bearing journals and the bedplate and then secure the bedplate in place, lubricating the bedplate retaining bolts with clean oil first. Put in the bedplate retaining bolts with the stud bolts in the proper locations and apply the recommended sequence of torque to them, including hand tightening some and using 54 Nm (40 ft. lbs.), 7 Nm (5 ft. lbs.) and another 90° on others before tightening to 27 Nm (20 ft. lbs.). First check the crankshaft's end play, reach the right side clearance for the connecting rods, add and test the oil pump and finally, secure the engine back into place.