JeepParts

My Garage

My Account

Cart

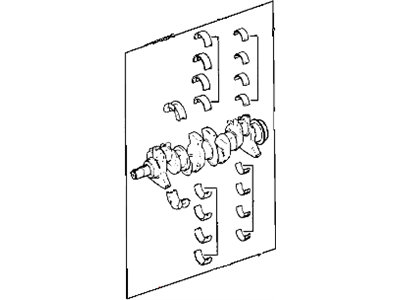

OEM Dodge Dakota Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Crankshafts found

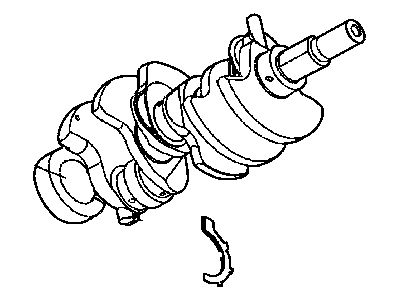

Dodge Dakota Crankshaft Part Number: 53020959AB

$629.85 MSRP: $959.00You Save: $329.15 (35%)Ships in 1-2 Business Days

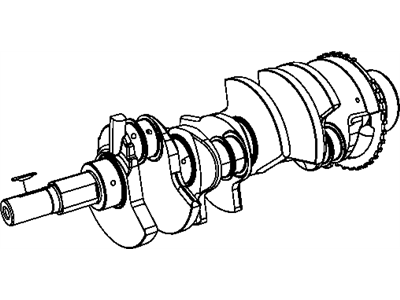

Dodge Dakota Crankshaft Part Number: 53022286AA

Dodge Dakota Crankshaft Part Number: R4790759AB

Dodge Dakota Crankshaft Part Number: 53021407AB

Dodge Dakota Crankshaft Part Number: 53021387AA

Dodge Dakota Crankshaft Part Number: 53020603

Dodge Dakota Crankshaft Part Number: 53020601

Dodge Dakota Crankshaft Part Number: 4713051AB

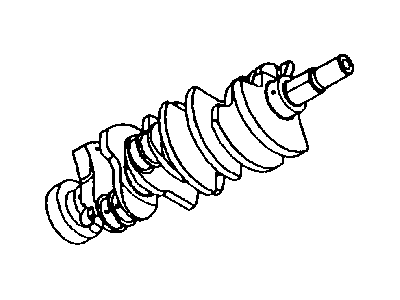

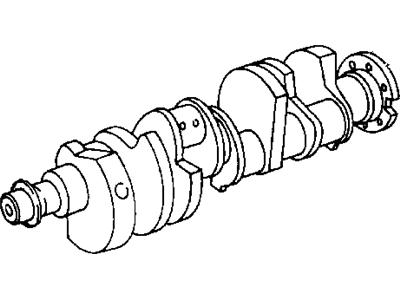

Dodge Dakota Crankshaft

Choose OEM Crankshaft that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Crankshaft follows strict manufacturing steps to lock in quality and fit. If your Dodge Dakota matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Dakota parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Dakota Crankshaft Parts and Q&A

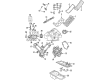

- Q: How is the Crankshaft Removed from an Engine on Dodge Dakota?A:An engine must be pulled out first before the crankshaft can be taken out. The first thing to do is remove the engine and then get the engine oil pump out. When taking off the Oil Pan, avoid putting too much pressure on the gasket, as it won't separate from the block when the oil pan is removed. Following this, take out the bedplate mounting bolts and remember where the two stud bolts are. Remove the connecting rods from the crankshaft to avoid destroying the key sealing area between the bedplate and the cylinder block. Take care when holding the bedplate because it holds the lower main bearing parts and if you misplace or damage them, the crankshaft may be badly damaged. Use the special edges in the bedplate to gently pry it off. Lastly, take out the crankshaft without harming the bearings on which it sits.

- Q: How is the Crankshaft Installed in an Engine on Dodge Dakota?A:Install the crankshaft and be certain that the main bearings are press fit. Then, before going on, grease the tone wheel screws and any other gaskets. Add clean engine oil to the upper main bearing halves, fit the crankshaft into the cylinder block and set in the thrust washers. Please cover the bedplate to cylinder block mating surface with Mopar® Engine RTV sealant so that clean sealing surfaces can protect against severe oil leaks. Cover the Mopar® Engine RTV sealant along the mating surface between the cylinder block and the bedplate. Then, oil the crankshaft main bearings by hand and put the bedplate on the cylinder block. Apply clean engine oil to the bedplate bolts before putting them back, to confirm the stud bolts are all in their appropriate holes. Start by hand tightening bolts 1D, 1G and 1F, so the bedplate rests against the block, then tighten bolts 1A - 1J to 54 Nm (40 ft. lbs.) and after that all bolts 1 - 8 to 7 Nm (62 in. lbs.), extending bolts 1 - 8 by 90° and finally tightening bolts A - E to 27 Nm (20 ft. lbs.). Do a crankshaft end play test, match the connecting rods' side clearance, set up the oil pump and finish with the engine install.