JeepParts

My Garage

My Account

Cart

OEM 2005 Dodge Dakota Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Crankshafts found

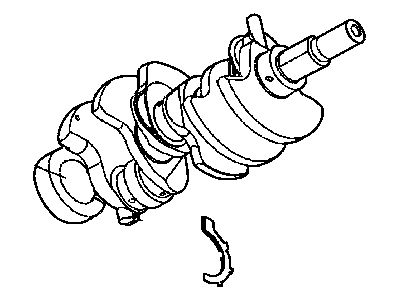

2005 Dodge Dakota Crankshaft Part Number: 53020959AB

$629.85 MSRP: $959.00You Save: $329.15 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft; Crankshaft See Note

- Item Weight: 48.20 Pounds

- Item Dimensions: 28.4 x 10.1 x 8.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53020959AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

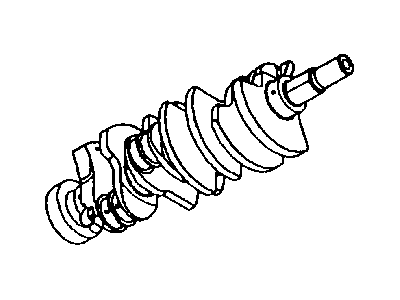

2005 Dodge Dakota Crankshaft Part Number: 53021387AA

Product Specifications- Other Name: Crankshft

- Item Weight: 59.60 Pounds

- Item Dimensions: 30.6 x 9.3 x 7.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53021387AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

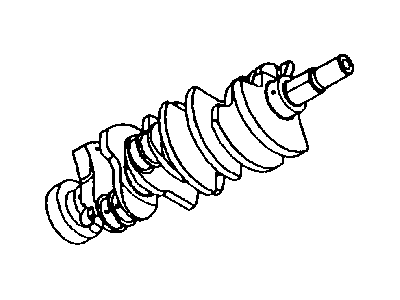

2005 Dodge Dakota Crankshaft Part Number: 53021407AB

Product Specifications- Other Name: Crankshft

- Item Weight: 44.50 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53021407AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Dodge Dakota Crankshaft Parts and Q&A

- Q: How to Remove and Install a Crankshaft in an Engine on 2005 Dodge Dakota?A: Remove the vehicle's engine and, afterward, disconnect the engine oil pump from the engine. Don't try to remove the oil pan gasket, as it is anchored to the cylinder block in a number of spots and will remain attached when you take the oil pan off. After that, unbolt the bedplate, note where the stud bolts go and pull out the connecting rods being careful not to damage the sealing area at the bottom of the engine. Since the lower main bearing halves are in the bedplate, be very careful with it to avoid injuring or dropping the bearings, otherwise the crankshaft can be badly damaged. Apply pressure to the pry points placed in the bedplate to loosen and remove it and next, carefully take out the crankshaft and the crankshaft tone wheel. Check all bearing bores, both for the connecting rod and main, for any damage that might cause the engine to disassemble further. If wear is spotted in the connecting rod bearing bores, the piston and rod assemblies must be serviced with the cylinder heads off; if the bedplate or cylinder block main bearing bores are damaged, the engine needs to be changed. Should this be needed, split the main bearing halves apart from the cylinder block and bedplate, then clean the seal surfaces and main bearing bores and check the bedplate main bearing bores for damage like wide blueing or cracks which require an engine to be replaced. Check for wear or scoring on the crankshaft thrust washers and also pull out and check the oil pan gasket/windage tray for any splits or cracks, replacing as necessary. Don't harm the bearing surfaces as you fit the crankshaft and remember to use sealant on the screws that secure the tone wheel. Lubricate between the two main bearing pieces using clean engine oil, put the crankshaft tone wheel in place and tighten the mounting screws for the upper main bearing to 15 Nm (11 ft. lbs.). Set the crankshaft inside the cylinder block, add the thrust washers, then cover the bedplate to cylinder block seal with Mopar® Engine RTV sealant to stop severe leaks. Remove any dirt from the sealing area, apply a 0.100 inch sealant ring to the mating surface, rub the engine oil onto the main journals and set the bedplate carefully over the cylinder block. Before you install it, smooth some clean oil along the bedplate retaining bolts, put them in place, make sure the stud bolts are lined up properly and torque them in the correct order. Start by hand tightening bolts 1D, 1G and 1F until the bedplate touches the block. Then, tighten all other bolts to 54 Nm (40 ft. lbs.), then bolts 1 - 8 to 7 Nm (5 ft. lbs.). Go further and tighten bolts A - E an additional 90° and to 27 Nm (20 ft. lbs.). Compare crankshaft end play, bolt in the connecting rods and check their side clearance and then fit the oil pump and the engine.