JeepParts

My Garage

My Account

Cart

OEM 2004 Dodge Durango Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Crankshafts found

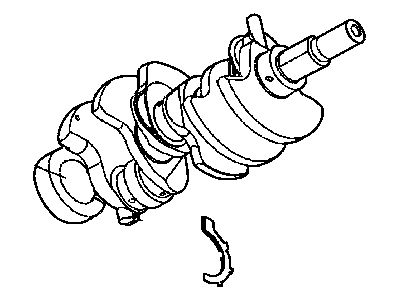

2004 Dodge Durango Crankshaft Part Number: 53020959AB

$629.85 MSRP: $959.00You Save: $329.15 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft; Crankshaft See Note

- Item Weight: 48.20 Pounds

- Item Dimensions: 28.4 x 10.1 x 8.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53020959AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

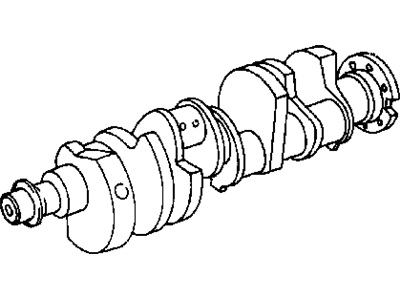

2004 Dodge Durango Crankshaft Part Number: 53021302AD

Product Specifications- Other Name: Crankshft; Crankshaft Includes Tone Ring And Tone Ring Mounting Screws

- Item Weight: 64.00 Pounds

- Item Dimensions: 29.6 x 8.5 x 7.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53021302AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

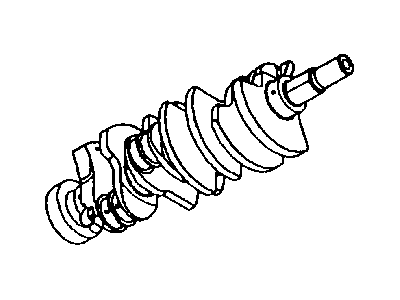

2004 Dodge Durango Crankshaft Part Number: 53021387AA

Product Specifications- Other Name: Crankshft

- Item Weight: 59.60 Pounds

- Item Dimensions: 30.6 x 9.3 x 7.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53021387AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2004 Dodge Durango Crankshaft Parts and Q&A

- Q: How to Safely Extract the Crankshaft from an Engine on 2004 Dodge Durango?A: In order to remove the crankshaft out of the engine, one should initially ensure that the engine is pulled out of the car before the engine oil pump is pulled out. It is important to avoid prying along the oil pan gasket since this gasket is attached to the cylinder block in three positions thus it cannot be removed alongside oil pan. Then the bedplate mounting bolts are removed and the two stud bolts put in a place so they can be reinstalled, and finally the connecting rods could be detached off the crankshaft but care must be taken not to damage the sealing surface of the bedplate to cylinder block. Base plate where the halves of the lower main bearings are even in should be lifted so as not to throw the bearing halves on the ground and care is to be taken it should not be dropped (Mistakes may cause very serious destruction to the crankshaft). Loosen and remove the bedplate by the use of the pry points cast in the bedplate, then the crankshaft and crankshaft tone wheel. Check connecting rod bearing bores and main bearing bores to see whether they are scored, blue or heavily scribed because additional disassembling may be want to pull. When the connecting rods bearing bores are damaged, the piston and rod assemblies should also be serviced; this will require the removal of the cylinder heads; when main bearing bores in bedplate or cylinder block are damaged, replacement of the engine is in order. Should this be necessary the sealing surfaces on the night bearing sides of the cylinder block and bedplate should be carefully cleaned, and main bearing bores wiped clean. Look to see how the crankshaft thrust washers are, and look at oil pan Gasket / windage tray to see that there is not a split or crack, replacing as required. Bearings used in the crankshaft must be select fit when fitting the crankshaft, care of the bearing surfaces should be taken to rule out premature bearing wear. Before installing the tone wheel retaining screws apply sealant to them, lubricate the upper bearing half with clean engine oil and install the crankshaft tone wheel, torquing the mounting screws to 15 Nm (11 ft. lbs.). Install the crankshaft in the cylinder block and add the thrust washers and then cover the bedplate to cylinder block mating surface with Mopar Engine RTV sealant to ooze oil back. Make the sealing surfaces clean and without contamination and put a 2.5 mm (0.100 inch) (clearance) bead of Mopar Engine RTV sealant onto the mating surface, and apply clean engine oil to the crankshaft main bearing journals, and seat the bedplate onto the cylinder block. Clean engine oil all the bedplate retaining bolts beforeinstallation, and then install them, make sure the stud bolts are in the right position, and they are torqued in the order requirements. Tighten bolts 1D, 1G and 1F until the bedplate rises against the block and torque the bolts 1A -1J to 54 Nm (40 ft. lbs.), then the bolts 1 to 8 to 7 Nm (5 ft. lbs.), turning the bolts 1 to 8 another 90 and finally, the bolts A to E to 27 Nm (20 ft. lbs.). Crankshaft end play; install connecting rods side clearance and reinstall oil pump, and engine.