JeepParts

My Garage

My Account

Cart

OEM 2004 Jeep Wrangler Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

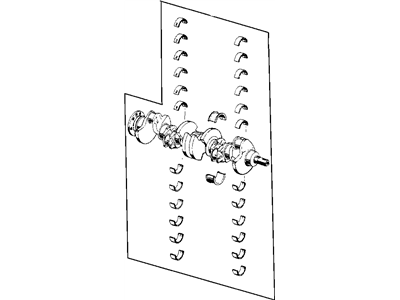

2 Crankshafts found

2004 Jeep Wrangler Crankshaft Part Number: 4864726AD

Product Specifications- Other Name: Crankshft

- Replaces: 4864726AB, 4864726AC

- Item Weight: 64.80 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4864726AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2004 Jeep Wrangler Crankshaft Part Number: 4621917

Product Specifications- Other Name: Crankshft; Crankshaft, Machined

- Item Weight: 50.80 Pounds

- Item Dimensions: 23.3 x 8.8 x 8.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 4621917

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

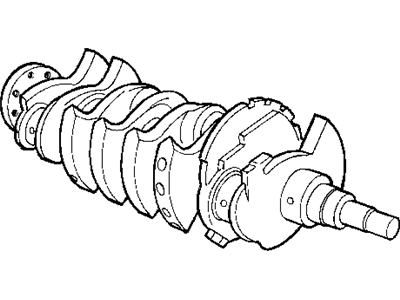

2004 Jeep Wrangler Crankshaft Parts and Q&A

- Q: How to Remove and Replace a Crankshaft in an Engine on 2004 Jeep Wrangler?A: The first step is to take out the engine, then you should get rid of the flex plate and the crankshaft rear oil seal ahead of installing the new crankshaft. After that, the engine should be put on a repair stand and both the engine oil and its filter should be drained. After that, the oil pan, timing belt covers, timing belt, oil pump and balance shafts with housing assembly must be taken apart. Make sure to remove every bedplate bolt where the engine rests on the bedplate and gently tap the bedplate so it lifts evenly from the dowel pins. The crankshaft may be lifted from the cylinder block without touching or damaging the main bearings or journals. Special care must be taken to avoid over-working the crankshaft journals, especially by inspecting for excessive wear, taper and scoring and grinding no more than 0.305 mm (0.012 inch) below the standard diameter. Following the grinding process, remove any rough edges around the oil holes and continue by finishing the nodular cast iron crankshaft to match the turning motion it follows. When fitting main bearing shells, the lubrication groove should be on the cylinder side to allow proper alignment of the oil holes and their tabs. Oil should not be on the bedplate mating surface and the crankshaft bearings and journals should be oiled before the crankshaft is mounted. The only recommended sealer for the bedplate should be used, with 1.5 to 2.0 mm of Mopar Bed Plate Sealant placed around the cylinder block. Place lower main bearings into the main bearing cap/bedplate with bearing tabs in place and then fit the main bearing/bedplate into the engine block. Before installing them, grease the threads on all bolts and hold bolts 11, 17 and 20 together, tightening them until they contact the cylinder block. To properly align the thrust bearing, align the number 4 piston to TDC, then move the crankshaft to each limit, making sure a tool is put between the rear of the cylinder and the crankshaft's rear counterweight to ensure it stays forward. First, put together and tighten bolts 1 through 10 to a torque of 41 Nm (30 ft. lbs.) and finish by tightening them again, just adding one-fourth of a turn. Before assembly, torque main bearing bedplate to engine block bolts (11 - 20) to 28 Nm (20 ft. lbs.) and ensure that the crankshaft turning torque is no more than 5.6 Nm (50 inch lbs.). All final steps, including the balance shafts and housing assembly, oil pump and pickup tube, the timing belt rear cover, timing belt front covers, engine support bracket, oil pan, oil filter, crankshaft rear oil seal and flex plate, should be fitted with Mopar Lock & Seal Adhesive applied to the bolt threads of the flex plate and carefully tightened to 95 Nm (70 ft. lbs.).