JeepParts

My Garage

My Account

Cart

OEM 2007 Dodge Ram 1500 Timing Chain

Engine Timing Chain- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Timing Chain found

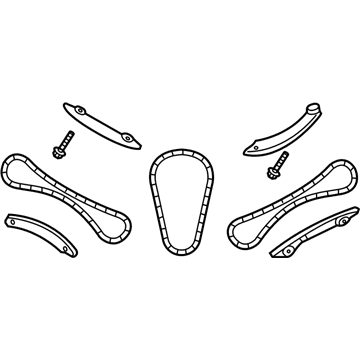

2007 Dodge Ram 1500 Timing Chain Part Number: 5019423AD

Product Specifications- Other Name: Chain - Engine Timing; Engine Timing Chain Kit; Drive Assembly; Timing Drive Package; Chain & Gear Kit Engine Timing; Timing Drive Package Engine

- Replaces: 5019423AC

- Item Weight: 5.80 Pounds

- Item Dimensions: 10.1 x 8.8 x 3.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5019423AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2007 Dodge Ram 1500 Timing Chain Parts and Q&A

- Q: How to Remove and Replace a Timing Chain on 2007 Dodge Ram 1500?A: Slightly compress the secondary chain tensioner piston (5) until it is tight against the tensioner body, then use your hand to pull back the ratchet pawl held in place by its spring through the side of the tensioner. As you press on the pawl, place Special Tool 8514 lock pin (3) in the front hole of the tensioner, just after removing the ratchet device from the tensioner body by about 2 mm. Open the vise (1) gradually so that the piston spring pushes on the lock pin. Mount the chain tensioner where the oil pump is, insert bolts into the lower two holes of the tensioner bracket and tighten to 28 Nm (250 in. lbs.). Insert the right side chain tensioner arm by using a Torx(R) bolt and tighten it at 28 Nm (250 in. lbs.), then install the left side chain guide and tighten both bolts to the same value, 28 Nm (250 in. lbs.). After that, fit the left side chain tensioner arm and bolt, tightening them to 28 Nm (250 in. lbs.), then fit the right side chain guide with bolts tightened to 28 Nm (250 in. lbs.). Slide the primary chains on the lower jaw, guided by Special Tool 8429 (1), so that the incisor (top of the chain) meets the front plate of the transmitter gear. Place the two strong links on the double plated side against the timing point at 12 o'clock on the idler sprocket. Put the weaker single-plated link against the timing mark at 6 o'clock on the crankshaft sprocket. Use clean engine oil to grease the idler shaft and bushings and time the idler sprocket to the counterbalance shaft drive gear before fully fitting it. First, put in all the chains together with the crankshaft and idler sprockets and then guide both secondary chains through the block and cylinder head openings, attaching them with an elastic strap to stop them from being loose. Fit (2) on (3) together and seat (3) all the way down while fitting the upper and lower bolt. Wipe oil over the washer before tightening the idler sprocket assembly retaining bolt to 34 Nm (25 ft. lbs.) and gently rotate the camshafts to install the sprockets. Match the marks "L" and "R" on both the camshaft sprocket to the plated links on the chain and remember to remove all extra oil before tightening the bolts. After removing Special Tool 8429, hold both sprockets against the twin cams and eyelet and attach the sprocket bolts by hand. Ensure all plated links line up with the marks on all sprockets, including the "V6" mark near the top of every camshaft sprocket and make sure the plate between the left secondary chain tensioner and block is correctly set. Attach both set tensioners to the secondary chain, tighten the mount bolts to 28 Nm (250 in. lbs.) and take out all locking pins from them so you don't accidentally extend the tensioner ratchet. Set the sprocket bolts using Special Tool 6958 and Spanner with Adaptor Pins 8346 to a torque of 122 Nm (90 ft. lbs.). Rotate the engine two full revolutions and check that the timing marks are lined up: the primary chain idler sprocket dot is at 12 o'clock, the primary chain crankshaft sprocket dot is at 6 o'clock, the secondary chain camshaft sprockets "V6" marks are at 12 o'clock and the counterbalancer shaft drive gear is with the idler sprocket gear dot. Put engine oil on the chains, check that the idler gear's backend play is between 0.10 and 0.25 mm (0.004 and 0.010 in.) and replace it if needed. Place the timing chain cover and the crankshaft damper next, adding the cylinder head covers after that, but first coat the threaded plug with sealant if it's in the right cylinder head to avoid leaks. Use Mopar(R) Thread Sealant with Teflon on the large threaded access plug, set it into the right cylinder head (1) and tighten it to 81 Nm (60 ft. lbs.). Install the oil fill housing, access plug in the left cylinder head (2), fit the power steering pump and fill the cooling system with water. Then, connect the negative battery cable.