JeepParts

My Garage

My Account

Cart

OEM 2008 Chrysler Aspen Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Rod Bearings found

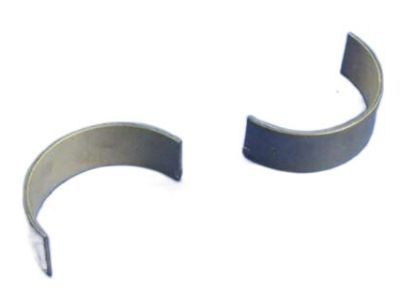

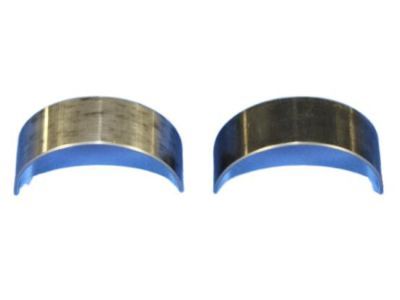

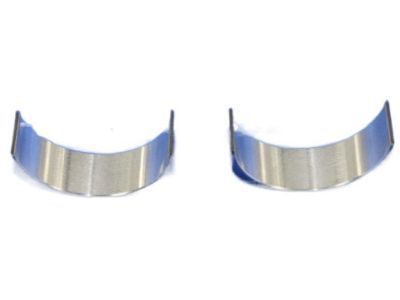

2008 Chrysler Aspen Connecting Rod Bearing Part Number: 68207790AA

$6.32 MSRP: $7.70You Save: $1.38 (18%)Product Specifications- Other Name: Bearing Package - Connecting Rod; Rod Bearing; Bearing; Bearings; Bearing Kit Connecting Rod Standard

- Replaces: 5086003AB

- Item Weight: 0.50 Pounds

- Item Dimensions: 3.8 x 2.6 x 1.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 10

- SKU: 68207790AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

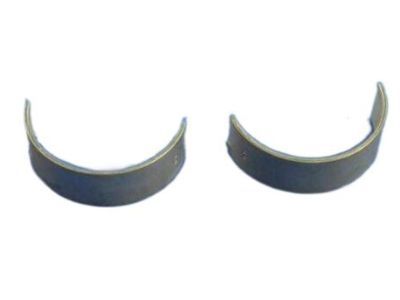

2008 Chrysler Aspen Bearings Part Number: 5012363AE

$16.87 MSRP: $25.00You Save: $8.13 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing - Connecting Rod; Rod Bearing; Bearing Kit Connecting Rod Standard See Note; Bearing Kit Connecting Rod Standard

- Replaces: 5012363AC, 5012363AD, 5018584AB, 5012363AB

- Item Weight: 0.50 Pounds

- Item Dimensions: 4.0 x 2.7 x 2.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5012363AE

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2008 Chrysler Aspen Rod Bearing Parts and Q&A

- Q: How to Inspect and Replace Rod Bearings While Ensuring Proper Alignment and Clearance on 2008 Chrysler Aspen?A: Look at the connecting rod bearings to check for scratches, normal signs of wear, grooves, tired areas and pitting. If a bearing shows more damage than usual, replace it. Review the connecting rod journals for any scoring, nicks or burrs because unaligned or bent connecting rods may cause uneven wear to pistons, piston rings, cylinder walls, bearing part and crankshaft journals. Damaged or misshapen gear teeth might indicate an alignment problem; check the connecting rods and change any bent or twisted rods. Oil the connecting rod journal and then, after cleaning, slide 2 into the connecting rod, putting it into a central position. Position piston ring compressor 3 and Guide Pins Special Tool 8507 4 together to put in the rod and piston assemblies, checking that the oil slinger slots in the rods are facing the front of the engine and the "F" on the piston points forward to the threshold of the crankshaft. Place the lower insert into the bearing cap while keeping it dry, put a strip of Plastigage over the entire center of the insert and secure it so it doesn't deteriorate. Place the bearing cap and connecting rod onto the journal, tightening bolts by hand until they reach 27 Nm (20 ft. lbs.) and refusing to turn the crankshaft while tightening, to prevent Plastigage smearing. Take off the bearing cap to check the distance between the two lines of compressed Plastigage 2 and ensure that the bearing to journal clearance is proper, following the engine specifications. After assessing that it is a fitting clearance, remove the Plastigage from the crankshaft journal and insert to move on to installation. If the clearance is greater than allowed, choose the right service bearing set. Remember to replace the connecting rod bolts, because they are Torque to Yield Bolts and should not be put back in place. Measure the Plastigage again to make certain the bearings are the right choice prior to assembly. Place the insert and the cap, then tighten the connected rod bolts to 27 Nm and turn them 90 degrees more. Try to measure the gap between the connecting rod and crankshaft journal flange using a snug-fitting feeler gauge and comparing it to what the manual says. If the measurement is too high or too low, replace the connecting rod.