JeepParts

My Garage

My Account

Cart

OEM 2009 Chrysler Aspen Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Rod Bearings found

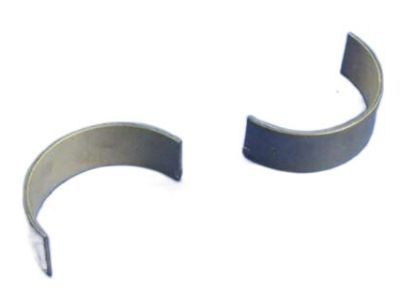

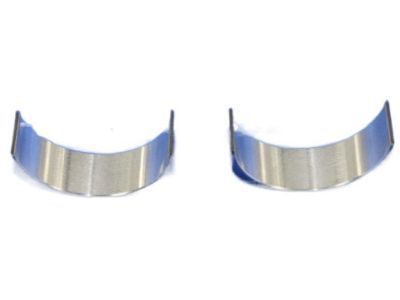

2009 Chrysler Aspen Connecting Rod Bearing Part Number: 68207790AA

$6.32 MSRP: $7.70You Save: $1.38 (18%)Product Specifications- Other Name: Bearing Package - Connecting Rod; Rod Bearing; Bearing; Bearings; Bearing Kit Connecting Rod Standard

- Replaces: 5086003AB

- Item Weight: 0.50 Pounds

- Item Dimensions: 3.8 x 2.6 x 1.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 10

- SKU: 68207790AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

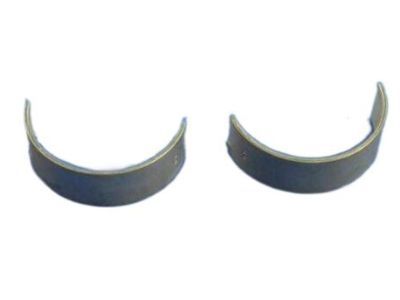

2009 Chrysler Aspen Bearings Part Number: 5012363AE

$16.87 MSRP: $25.00You Save: $8.13 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing - Connecting Rod; Rod Bearing; Bearing Kit Connecting Rod Standard See Note; Bearing Kit Connecting Rod Standard

- Replaces: 5012363AC, 5012363AD, 5018584AB, 5012363AB

- Item Weight: 0.50 Pounds

- Item Dimensions: 4.0 x 2.7 x 2.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5012363AE

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2009 Chrysler Aspen Rod Bearing Parts and Q&A

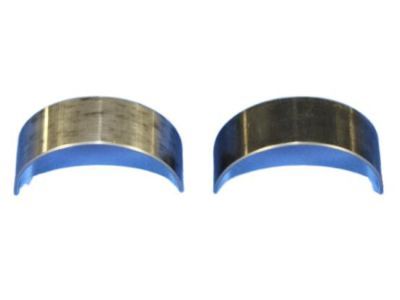

- Q: How to Ensure Proper Alignment and Clearance When Inspecting and Installing Rod Bearings on 2009 Chrysler Aspen?A: Check the connecting rod bearings for scoring, normal wear, trails made by wear, damage from fatigue and small holes caused by pitting and replace those that have unusual signs of wear. Make sure the journals on the connecting rod do not have any scoring or burrs, because misaligned connecting rods may cause the pistons, piston rings, cylinder walls, connecting rod bearings and crankshaft connecting rod journals to wear out abnormally. Should the positions of the dents or marks point to a misalignment, check the connecting rod for alignment problems and replace any that are off, bent or twisted. Clean the connecting rod journal with oil, wipe it off and add grease to bearing insert 2, placing it inside connecting rod 1. Install the rod and piston assemblies using piston ring compressor 3 and Connecting Rod Guides 8507 4, making certain that the oil slinger slots are at the front of the engine and the "F"s in the piston point forward. Dry the inserts, install the lower part in the bearing cap and then put a strip of Plastigage in the middle of the cap, making certain it doesn't crumble. Set the bearing cap and connecting rod in place on the journal, using sufficient torque of 27 Nm (20 ft. lbs.) and a 90° turn before tightening, so the crank does not try to spin. Take off the bearing cap and check the height of the compressed Plastigage to see if the bearing-to-journal clearance is approved by the Engine Specifications. If it passed, you can now take the Plastigage from the journal and insert and finish the installation process. If the clearance is more than allowed, pick out the fitting service bearing set from our database. Replace the Torque to Yield Rod Bolts whenever you take them out or they start to turn loose. Calculate Plastigage reading again to ensure the bearing is the right fit prior to putting everything together. After you have the insert chosen, put it and the cap in place, tightening the connecting rod bolts to 27 Nm (20 ft. lbs.) plus 90° of rotation. Fit a measuring gauge as tight as possible between the connecting rod and crankshaft journal flange, checking against the manual for clearance. Change the connecting rod if the gap is not according to specification.