JeepParts

My Garage

My Account

Cart

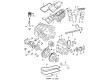

OEM Chrysler Concorde Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Rod Bearings found

Chrysler Concorde Connecting Rod Bearing Part Number: 4626657AD

$16.53 MSRP: $24.35You Save: $7.82 (33%)Ships in 1-2 Business Days

Chrysler Concorde Bearings Part Number: 5161294AA

$18.30 MSRP: $27.05You Save: $8.75 (33%)Ships in 1-2 Business DaysChrysler Concorde Bearings Part Number: 68000512AB

$41.06 MSRP: $61.30You Save: $20.24 (34%)Ships in 1-2 Business Days

Chrysler Concorde Rod Bearing

Choose OEM Rod Bearing that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Rod Bearing follows strict manufacturing steps to lock in quality and fit. If your Chrysler Concorde matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Concorde parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Chrysler Concorde Rod Bearing is a critical part that contributes to the boosting of its reliability and performance of Chrysler's full-sized sedan the Concorde. Being a very robust part due to the high load acting on it the Rod Bearing is responsible for holding the crankshaft and connecting rods and helping in rotation while bearing very less friction which is crucial for engine optimization. Chrysler Concorde series of cars manufactured between 1993 and 2004 can use these Rod Bearings that come in bi-metal and tri-metal variants as a result of the car's enhanced engineering. The bi-metal construction design has an aluminium alloy liner and the tri-metal version has a strong copper amalgam layer for enhanced durability as a result of the continuous usage on the roads and for high performance. Although it may not seem a glamorous part of a car, the Chrysler Concorde Rod Bearing is vital as it bear essential responsibility of ensuring that the communication between the engine's journals is smooth and the oil clearance is standard for efficient safety and lowered levels of wear. This is especially so in view of other enhancements that have been made with regards to the Concorde specific to a stiffer body shell and improved suspension. Also, the sectoration specific to the automotive market comprises unique features, including patent dry film coatings that make the Rod Bearing resilient not only to normal but also to overwhelming driving conditions. Because it could fit several Chrysler Concorde models, the Rod Bearing exemplifies Chrysler's constant drive for quality and performance, hence, should remain an integral aspect of the Chrysler Concorde engineering.

Chrysler Concorde Rod Bearing Parts and Q&A

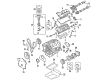

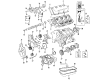

- Q: How Are Rod Bearings Properly Serviced and Repaired on Chrysler Concorde?A:For bearing service and repair, use the usual routine that covers machining and fitting needed for an engine overhaul, involving the cylinder block, cylinder bore, connecting rod and bearings, Crankshaft and bearings, valve train elements, changing the oil and fitting Pistons and rings. Assembling and disassembling the unit's subassemblies involves service for the cylinder head, the cylinder block, hydraulic tappets if present, oil pump and valves. Procedures focused on cleaning and inspection include the cylinder head, the cylinder block, the Camshaft and its journals, the crankshaft and its journals, intake and Exhaust Manifolds and components of the valve train. If no separate procedure is listed for a particular internal engine part, it means the manufacturer did not supply one.

- Q: What Precautions Are Essential for Proper Rod Bearing Installation to Prevent Engine Damage on Chrysler Concorde?A:Work on one bank at a time, putting all the connecting rods in place and make sure to notice how the bearing caps are labeled when removing them so you can assemble everything right. You should avoid any damage to the fractured rod and cap joint face so that the engine remains unharmed. Slide the bearing rings up on both rods, so that the tangs are fitted into the holes in the ends of all the rods and caps. Position the cap on the same side as the rod so that the hole in the upper bearing half is aligned with the oil squirt hole. To keep the engine safe, it's important that the hole in the upper half of the bearing matches the hole in the connecting rod. It is best to observe a maximum layer thickness of 0.015 mm or less on any crankshaft journal. Suitable bearings for this include those in 0.250 mm, 0.025 mm and 0.0006 inch undersize. When putting in the bearings, set one pair at a time, never use a fresh half with an old one and don't change or file anything. When checking Main Bearing Clearance and Connecting Rod Bearing Clearance, follow the instructions in Engine Specifications and use plastigage. Before you re-use a bolt, look for signs of stretching; if the threads are damaged, then replace it. Connecting rod bolts sit in the rod cap with a slight press fit, so use a hammer and punch to drive them out when removal is needed and avoid disturbing the screwed cap. If the scale or straight edge holds away from some of the threads, you should replace the connecting rod bolt. First, grease the threads of the screws with engine oil, put the bolts together by hand and then tighten each nut alternately until everything is in place. Put a dial indicator on a still point on the engine, so that its probe is resting against and perpendicular to the connecting rod cap being inspected. Shift the connecting rod to its furthest backstop, put the dial indicator at zero and then bring the connecting rod to its front stop and measure the dial indicator. Make sure the connecting rod's measurement matches the literature value by repeating the process on every connecting rod, as you rotate the crankshaft for accessibility.