JeepParts

My Garage

My Account

Cart

OEM Chrysler LHS Intake Valve

Engine Intake Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Intake Valves found

Chrysler LHS Intake Valve Part Number: 4663836

$26.34 MSRP: $38.35You Save: $12.01 (32%)Ships in 1-2 Business DaysChrysler LHS Intake Valve Part Number: 4663345

Chrysler LHS Intake Valve

Choose OEM Intake Valve that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Intake Valve follows strict manufacturing steps to lock in quality and fit. If your Chrysler LHS matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine LHS parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

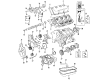

This Chrysler LHS Intake Valve is an important component that greatly contributes to performance and durability of Chrysler LHS automobiles. Measured to an exact tenth of a millimeter, the newly designed AVS intake valve is the most important component in the management of the air/fuel mixture and in combustion efficiency. This reliability is very important since any change in the power output and emissions can lead to high expenses and hence the need to replace them as soon as possible. Chrysler LHS was manufactured between 1994 and 2001 and is famous for its luxurious design and the incorporation of modern qualities; the intake valve contributes to ensuring the said quality. The intake valve is versatile in that it can fit on most LHS models as it has been configured to work in harmony with the engine so as to promote the ideal running of the same. This paper will demonstrate that the function of intake valve cannot be overemphasized in ensuring the safety of vehicles since it plays a significant role in increasing fuel efficiency of the vehicle and thus reducing pollution. Most of the Chrysler LHS Intake Valve have features that make them highly durable especially when used in high performance vehicles and they are manufactured in a way that makes them fit in the vehicles they are meant for without say any challenges. Such attention to details gives the Chrysler LHS Intake Valve a competitive edge in the automotive market thus making it a go to company in ensuring the Chrysler LHS vehicles integrity. In conclusion, the Chrysler LHS Intake Valve is the epitome of Chrysler's quality work, something that sets the brand into the automobile market.

Chrysler LHS Intake Valve Parts and Q&A

- Q: How to Service and Repair Exhaust Valve and Intake Valves on Chrysler LHS?A:Before starting to service valve seats, check how much material is left after you have refaced the valves. Use the proper pilot when refacing seat valves to help stones be seated accurately and completely on the valve seats. Place a dial indicator on the valve seat and confirm that the spin-out does not go above 0.051 mm (0.002 inch). Try staining the seat with Prussian blue, setting the valve on it and turning it with your fingers; when the blue spreads to the middle of the valve face, you know there is proper contact. If the dye appears at the top, raise the valve seat with a small stone; if it's on the bottom, lower the valve seat with a large stone. If the proper width and angle of the valve seat are not maintained, the cylinder head can't be repaired and needs to be changed. Intake seats should measure between 0.75 and 1.25 mm (0.0296 to 0.0493 inch) and exhaust seats should be 1.25 to 1.75 mm (0.049 to 0.069 inch) wide. Cover the valve stems in clean oil and place them into the cylinder head. When you reface valves or seats, the valve tip's height should not exceed 43.65 mm for intake or 45.98 mm for exhaust; if it's higher, grind it down. Place the valve seal/spring seat assembly on every valve stem, making sure the garter spring is still present around the top of the rubber seal. Fit the valve springs, with the marked end up and the valve retainers into place on the spring seat. Work the valve springs in towards the piston using a compressor, slide the locks into place and let go of the tool. If a valve or seat has been refaced, check that the springs are measured at 38.75 mm (1.5256 inch) or less from top to bottom, since exceeding this distance could cause problems; if they are higher, use a 0.762 mm (0.030 inch) spacer found in the head counterbore under the valve spring seat to achieve the correct spring height.