JeepParts

My Garage

My Account

Cart

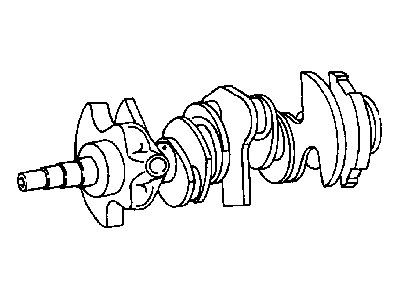

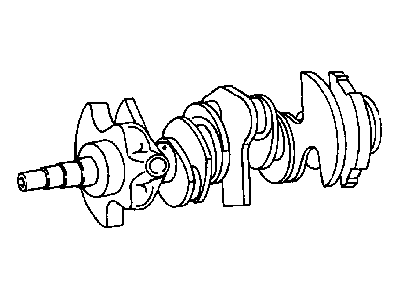

OEM Chrysler LHS Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Crankshafts found

Chrysler LHS Crankshaft Part Number: 4792333

$121.61 MSRP: $154.16You Save: $32.55 (22%)Ships in 1-2 Business DaysChrysler LHS Crankshaft Part Number: 4792692AB

Chrysler LHS Crankshaft

Choose OEM Crankshaft that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Crankshaft follows strict manufacturing steps to lock in quality and fit. If your Chrysler LHS matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine LHS parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Chrysler LHS crankshaft serves as the main reliable component for the Chrysler LHS vehicles produced between 1994 and 2001. This machined crankshaft performs a dual role by transforming piston back-and-forth motion into rotational force which powers the transmission and vehicle wheels accurately. Manufactured from cast iron materials for lower output engines yet high horsepower applications use forged steel to create the Chrysler LHS crankshaft which resists diverse driving conditions. The LHS model compatibility enables every vehicle to obtain better efficiency alongside safety enhancements which makes this component fundamental in maintaining peak engine operation. The Chrysler LHS crankshaft endures vehicle lifetime exposure only when owners follow maintenance routines yet poor care will generate scored journals accompanied by engine knock. The prevention of mechanical breakdown requires both frequent inspections of the crankshaft as well as prompt replacement schedule. The Chrysler model crankshaft shows exceptional market presence through its engineered excellence and sturdy design leading to enhanced driving quality. The car crankshaft builds performance and solidity while confirming the automaker's commitment to innovation and reliable vehicle production within the automotive field.

Chrysler LHS Crankshaft Parts and Q&A

- Q: How to Remove and Install a Crankshaft in an Engine on Chrysler LHS?A:First, pull out the engine from your vehicle and then get rid of the Oil Pan and pickup tube. Afterward, separate the crankshaft vibration damper, the idler pulley used on the accessory Drive Belt and the front lower, main and left side Timing Belt covers. Remove the tensioner of the timing belt, the belt itself and then the crankshaft sprocket. Get the dowel pin out of the crankshaft, then back out the oil pump assembly and the crankshaft rear oil seal retainer. Remove all the bearing caps from the connecting rod and the main bearings and remember to mark them so you reassemble them properly. The last step is to remove the crankshaft from the cylinder block. Check the crankshaft journals for scratches, wedging and excessive wear and keep limits of taper or out-of-round below 0.015 mm (0.0006 inch), making sure that journal grinding is within 0.305 mm (0.012 inch) of the standard journal diameter without damaging the thrust faces of the Number 2 main bearing or crankpin or its bearing fillets. Following grinding, wash and polish the crankshaft oil holes and passages in the same way the engine naturally rotates. To install, place the main bearings, put them into place and then put the crankshaft into the cylinder block. Move the crankshaft about halfway forward, apply special sealant to the thrust washers, install the front one, then move it all the way forward to install the rear washer. Before installing the main bearing cap bolts, slip them into engine oil and dry them with a cloth. For every main cap, put it on and turn the bolts only as tight as needed by hand. After that, tighten the main cap bolts in the proper order to 20 Nm and turn them 1/4 turn extra. Check crankshaft end play, install the connecting rods and measure clearance on the sides. Put in the windage tray, apply oil to its bolts and tighten them to 27 Nm + 1/4 turn. Tighten the main cap tie bolts to 28 Nm (250 in. lbs.), place the rear crankshaft oil seal retainer on top and set the oil seal in the retainer. Then, fit the oil pump assembly and fill the pump cavity with oil. Reenter the dowel pin into the crankshaft, set in the crankshaft sprocket and next install the camshaft sprockets and timing belt. Replace the timing belt cover, crankshaft vibration damper and idler pulley for the accessory drive belt. After the oil pump is up, fit the oil pickup tube and bolt it tight to 28 Nm (250 in. lbs.). Put in the oil pan, remount all the engine parts and oil the crankcase properly.