JeepParts

My Garage

My Account

Cart

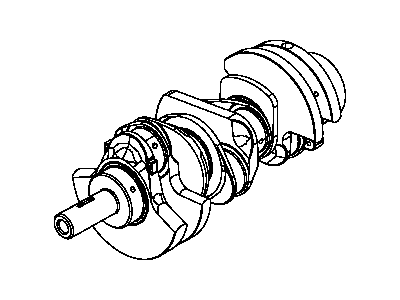

OEM Dodge Avenger Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Crankshafts found

Dodge Avenger Crankshaft Part Number: 5184251AI

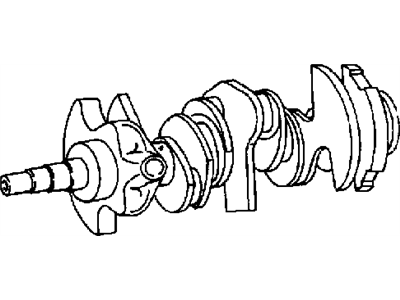

$570.18 MSRP: $860.00You Save: $289.82 (34%)Ships in 1-2 Business DaysDodge Avenger Crankshaft Part Number: 4663638

$1000.64 MSRP: $1485.00You Save: $484.36 (33%)Ships in 1-2 Business DaysDodge Avenger Crankshaft Part Number: 68001694AC

Dodge Avenger Crankshaft Part Number: 4792692AB

Dodge Avenger Crankshaft

Choose OEM Crankshaft that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Crankshaft follows strict manufacturing steps to lock in quality and fit. If your Dodge Avenger matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Avenger parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Avenger Crankshaft Parts and Q&A

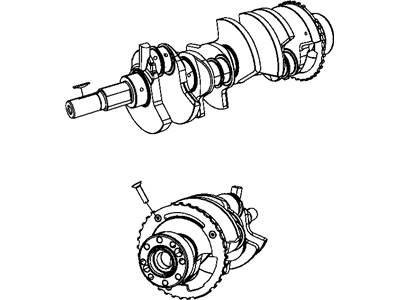

- Q: How to Safely Extract a Crankshaft from an Engine on Dodge Avenger?A:First, take out the engine from the vehicle, then disconnect the transaxle from it before you can remove the crankshaft. After that, the flex plate/flywheel must come off, along with the crankshaft rear oil seal. Then, set the engine on an appropriate repair stand and let the used engine oil drip out. After draining, it is necessary to remove the Oil Filter, the crankshaft vibration damper and the water pump pulley. Remove the engine mount bracket support, the Oil Pan and both the Timing Chain and cover. First, take out the balance shaft module and next remove the crankshaft sprocket. Unbolt the sensor retaining bolt and next unbolt the ladder frame to remove the sensor. Piston or connecting rod replacement requires that the cylinder head is taken off first. No number stamp or punch should be used on the connecting rods; only permanent ink or paint markers should be used to identify the cylinder number on every connecting rod and cap. When you remove all the connecting rod bolts and caps, handle them carefully, so your fracture rod and cap don't get damaged and replace every connecting rod bolt. After that, the top main bearing cap must be taken out and the crankshaft can be easily lifted from the engine block without harming the main bearings or journals.

- Q: What Are the Steps Involved in Installing a Crankshaft on Dodge Avenger?A:Main bearings for the crankshaft make five contacts, with all shells in the upper end of the crankcase having oil grooves and holes, while the lower end's shells are ungrooved. End play in the crankshaft is controlled by a two-piece thrust bearing fitted to the number three main journal. It's important to first clean the main bearing cap hole with the specified brake parts cleaner and blow out the holes with compressed air. Slide the upper bearing shells toward the oiling area in the block so that the oil holes and groove in each piece fit into the engine's oil holes correctly. When a crankshaft is sent for machine work, be sure it is balanced with the target ring attached. Mopar brake parts cleaner should be used to wash down the crankshaft and target ring which should then be dried with compressed air to get rid of oil and dust. Novak recommends swapping the mounting screws of the new ring and starting with the hardest, at location #1, as you tighten the screws to 13 Nm (110 in-lbs). Gently spread trans gel onto the thrust bearings, being careful they are positioned so the notches are facing the crankshaft while being installed. Carefully add the thrust bearings to the block and make sure the oil from your hand does not touch the ladder frame, since this will cause trouble with your RTV seal. Make sure to oil the bearings and journals before you put the crankshaft into the engine. Put the lower main bearings in the cap, so the tabs are seated properly and install the caps onto the engine block, first threading the bolts by hand but not tightening them too much. Line up the thrust bearing by rotating the crankshaft to TDC at number 4, moving it rearward until you reach its limit, moving it to its front limit and wedging a tool between the crankshaft counterweight and the rear of the cylinder block to keep it in the forward spot. Be sure to identify the bolt heads to find out the correct torque level for each set of main bolts, as every set calls for a particular value. When the bolt heads are correct for each machined hole as needed, begin with tightening to 15 Newton meters (11 foot pounds). Then, tighten the head again to 27 Newton meters (20 foot pounds). Finally, rotate the bolts another 45 degrees. If you find that the bolt heads do not join, tighten them up to 15 Nm, then up to 45 Nm and turn them another 45° as well. Take out the wedge tool and measure the crankshaft turning torque which needs to be under 5.6 Nm (50 in. lbs.) and check the crankshaft end play. Add the connecting Rod Bearings and caps and fit new bolts instead of using those that were formerly on the rods, tightening them to 20 Nm + 90° (15 ft. lbs.) + 90°. Assemble the ladder frame assembly, place the balance shaft module and fit the crankshaft position sensor after securing them all with a bolt. Once the cylinder head is off, put it back in and next, put on the front crankshaft sprocket, Timing Chain, timing chain front cover and Oil Pan. Slide in the rear and front crankshaft oil seals, the engine mount support bracket and the crankshaft vibration damper. Put in the water pump pulley, take away the engine from the stand and secure the engine lift chain. Insert the crankshaft rear oil seal and the drive plate/flex plate and install new bolts, tightening all to 95 Nm (70 ft. lbs.). Bolt the transaxle to the engine, using 101 Nm (75 ft. lbs.) of torque on each of the bellhousing bolts and then fit the engine assembly. Then, change the Oil Filter, top up with oil and coolant, check for leaks and place the engine cover.