JeepParts

My Garage

My Account

Cart

OEM Dodge Magnum Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

12 Brake Calipers found

Dodge Magnum Caliper Assembly, Red, Front Driver Side Part Number: 5175107AB

$636.90 MSRP: $960.00You Save: $323.10 (34%)Ships in 1-2 Business Days

Dodge Magnum Caliper Assembly, Red, Front Passenger Side Part Number: 5175106AB

$636.90 MSRP: $960.00You Save: $323.10 (34%)Ships in 1-2 Business DaysDodge Magnum Caliper, Rear Driver Side Part Number: 68548611AA

$67.75 MSRP: $148.00You Save: $80.25 (55%)Ships in 1-2 Business DaysDodge Magnum Caliper Assembly, Front Driver Side Part Number: 68548603AA

$132.16 MSRP: $194.00You Save: $61.84 (32%)Ships in 1-2 Business DaysDodge Magnum Caliper Assembly, Front Passenger Side Part Number: 68548602AA

$141.23 MSRP: $207.00You Save: $65.77 (32%)Ships in 1-2 Business DaysDodge Magnum Caliper, Rear Passenger Side Part Number: 68548610AA

$115.17 MSRP: $169.00You Save: $53.83 (32%)Ships in 1-3 Business DaysDodge Magnum Caliper, Rear Driver Side Part Number: 68548609AA

$135.56 MSRP: $200.00You Save: $64.44 (33%)Ships in 1-2 Business DaysDodge Magnum Caliper Assembly, Front Passenger Side Part Number: 68548604AA

$168.42 MSRP: $250.00You Save: $81.58 (33%)Ships in 1-3 Business DaysDodge Magnum Caliper, Rear Passenger Side Part Number: 68548608AA

$134.43 MSRP: $199.00You Save: $64.57 (33%)Ships in 1-2 Business DaysDodge Magnum Caliper Assembly, Front Passenger Side Part Number: 68548605AA

$168.42 MSRP: $250.00You Save: $81.58 (33%)Dodge Magnum Caliper Assembly, Black/Red, Rear Passenger Side Part Number: 5175108AA

$651.58 MSRP: $982.00You Save: $330.42 (34%)Ships in 1-2 Business DaysDodge Magnum Caliper Assembly, Black/Red, Rear Driver Side Part Number: 5175109AA

$440.72 MSRP: $982.00You Save: $541.28 (56%)Ships in 1-2 Business Days

Dodge Magnum Brake Caliper

Choose OEM Brake Caliper that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Brake Caliper follows strict manufacturing steps to lock in quality and fit. If your Dodge Magnum matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Magnum parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

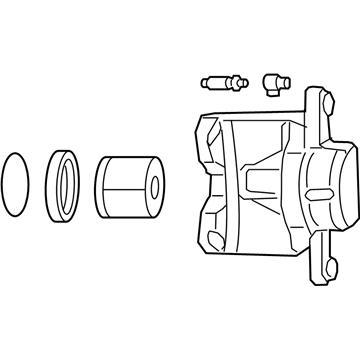

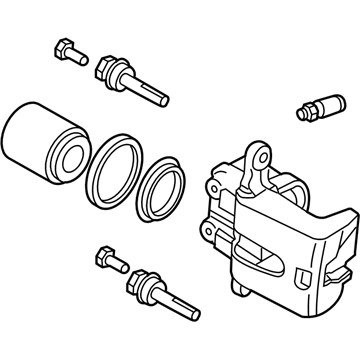

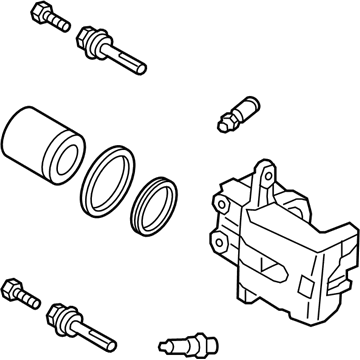

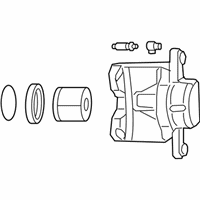

On Dodge Magnum vehicles, the Brake Caliper has a significant function in braking mechanism because it uses hydraulic pressure from the master cylinder to mechanical force. This force exerted on the brake pad pressed it against the rotors to slow or stop the car, as the case may be. Dodge Magnums utilize two primary types of brake calipers: Those in the fixed group are Those who were laid off from their jobs and the floating involves Those who are periodically out of work. This type usually has several pistons on both sides of the rotor as opposed to the floating type which has pistons only on one side that slides to exert pressure; due to the manner at which the floating calipers apply pressure on the rotor they are prone to wear if not well maintained. Decades of manufacturing Dodge Magnum brake calipers have used cast iron for the body and steel or phenolic material for the pistons. Additional types of calipers are performance parts' versions, which are more powerful and attractive compared to standard equipment. These performance calipers could hence vary from more economic to better and light ones, with differences in the drive of the respective users. As with any other part of a vehicle's braking system, it is critical to have the brake caliper checked periodically for such problems as leaks or uneven wear of pads.

Dodge Magnum Brake Caliper Parts and Q&A

- Q: How to Remove and Replace a Brake Caliper on an SRT8 on Dodge Magnum?A:It is important to inspect the Brake Pads before you replace the front brake caliper on an SRT8. Remove the complete slack from the pistons and have a block of wood or an aged brake pad, covering the end of the piston to prevent harm. Change the brake pads in the caliper if they need replacing, then go on to the next step. Slide the calipers with their pads against the brake rotor and place them up against the knuckle. Place the caliper mounting bolts and tighten them until you reach a torque of 190 Nm or 140 ft. lbs. Fit the brake hose onto the caliper bolted by two new washers and a new banjo bolt, with the bolt tightened to 33 Nm (24 ft. lbs.) torque. Slide the assembly onto the bolts and tighten them securely to 150 Nm (110 ft. lbs.). Drop the vehicle so it is at the ground level, take out the brake pedal and hook the negative cable to the car's battery post. Bleed the brake fluid system in the car as often as is required. When you get new brake pads, you should be careful because the first couple of brake uses might be a little less effective. To finish, take the car for a test drive and make a couple of stops to clean off anything extra on the brakes and shine up the new brake pads.

- Q: How to Service and Repair a Brake Caliper on a Front Single Piston Disc on Dodge Magnum?A:Before starting to service the single Piston disc brake caliper in front, disconnect the battery's negative cable from its post. Press the brake pedal past its first inch with a brake pedal holding tool to separate the master cylinder from the hydraulic brakes. Lift the vehicle up, remove the wheel from the mounting bolts and then take off the tire and wheel assembly. To disconnect the brake hose from the caliper, take out the banjo bolt, throw away the old washers and install new ones when you reassemble it. With the guide pins in place, take out the caliper guide pin bolts and pull the caliper off the brake adapter and its pads. Don't use high-pressure air to take out the piston from the caliper, since it can be dangerous. It's important to check and clean the caliper before taking it apart. Let the brake fluid drain, clamp the caliper in a vise on the jaws and cover the piston with a padded wooden block. Gently use low-pressure compressed air to move the piston out of the bore and remove it by hand. Be sure to avoid using metal tools while removing your seals to prevent harm. Clean the chamber and the drilled piston channels with alcohol or a good solvent, checking them for signs of damage. Wet the parts you're cleaning with water, then wipe them away, making sure any asbestos-contaminated cloths end up in an air-tight bin. You should clean and dry the area, well-oil the caliper piston, piston seal and bore with new brake fluid and fit a new piston seal and dust boot. Work the piston into the bore completely and then sit the dust boot in place using Special Tool 9315 and Special Tool C-4171. In the proper threaded hole, use the bleeder screw and tighten it to 15 Nm. Before fitting the caliper, pulling back the piston will let you examine the Brake Pads. Put the caliper on the adapter without crossing the guide pin bolts and then tighten them up to 60 Nm. Screw the banjo bolt back into place using new washers and tighten to 43 Nm. Put the tire and wheel assembly back on, tighten the nuts on the wheel mounts to 150 Nm, drive the vehicle down, release the brake tool, secure the cable from the battery negative terminal, flush the brake hydraulic system as required and check that everything works well on the road test.