JeepParts

My Garage

My Account

Cart

OEM Dodge Ram 3500 Intake Valve

Engine Intake Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Intake Valves found

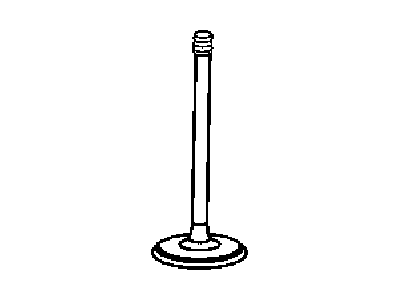

Dodge Ram 3500 Intake Valve Part Number: 53022087AC

$25.03 MSRP: $37.15You Save: $12.12 (33%)Ships in 1-2 Business Days

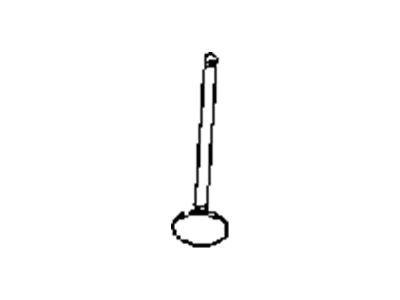

Dodge Ram 3500 Intake Valve Part Number: 5011879AA

$57.01 MSRP: $117.00You Save: $59.99 (52%)Ships in 1-2 Business DaysDodge Ram 3500 Intake Valve Part Number: 53006723

$19.33 MSRP: $24.50You Save: $5.17 (22%)Ships in 1-2 Business Days

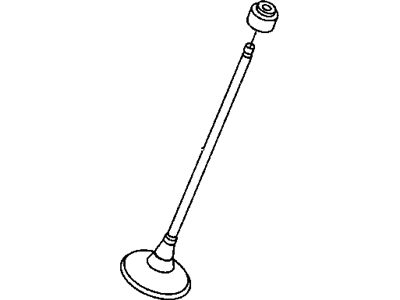

Dodge Ram 3500 Intake Valve Part Number: 53021550AA

Dodge Ram 3500 Intake Valve Part Number: 53005863

Dodge Ram 3500 Intake Valve Part Number: 4713216

Dodge Ram 3500 Intake Valve

Choose OEM Intake Valve that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Intake Valve follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 3500 matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 3500 parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Ram 3500 Intake Valve is one of the important parts that increase the performance and durability of Dodge Ram 3500 series. As a chief control mechanism of the air and fuel supply, Intake Valve has garnered significant importance in determining the engine power and effectiveness of combustion. The proper flowing of Intake Valve is important for the smooth running of the Dodge Ram 3500 to avoid problems that might cause failure of the engines and thus the need for repair. It is crucial to have this Intake Valve in the Dodge Ram 3500 because it is compatible with different models, thus sustaining the vehicle quality and performance. The Dodge Ram 3500 model contains the most sophisticated engine technologies, such as Direct Fuel Injection, which attracts the attention to the Intake Valve unique role in increasing productivity and minimizing risks. Special features of the Dodge Ram 3500 Intake Valve include the fact it is precision made to fit and be correctly seated when installed to enhance the efficient functioning of the vehicle's engine. Thus, owing to the position of Dodge Ram 3500 as a vehicle with heavy-duty construction coupled with the optimal performance of Intake Valve, it reinforces a proper reputation in the automotive industry. Owners increasing the priority of changing the damaged Intake Valves will guarantee the Dodge Ram 3500 stays a quality automobile in its full-size pickup truck market segment.

Dodge Ram 3500 Intake Valve Parts and Q&A

- Q: How to Remove and Replace Exhaust Valve and Intake Valves on Dodge Ram 3500?A:To change or repair the valves, first thoroughly clean valves 4 and 5 and get rid of those that look burned, warped or cracked. Stick a flexible cable hose into the guide to blast away buildup with a valve guide cleaner spray. Take the valve stem measurement; if it shows more than 0.051 mm (0.002 inch) of wear, get a new valve. Apply a little engine oil to the valve stems and put them into the cylinder head. If valve seats have been reground, you should also examine the valve stem height; if it's too long, the cylinder head should be changed. Change the valve seals, the valve springs and the retainers. Compress the valve springs using the C-3422 Compressor and 8464 adapter and afterward install the valve keepers. Spring measurement is done if the valves or seats are ground. Measure the height between the spring base in the cylinder head and the base of the spring retainer from the bottom. Afterward, assemble and install the cylinder head.

- Q: How to Service and Repair Exhaust Valve and Intake Valves on Dodge Ram 3500?A:To provide maintenance to the valve, first remove the cylinder head. To compress the valve springs, use the Valve Spring Compressor Tool MD-998772A with adapter 6716A and after compressing, pull out the valve retaining lock, valve spring retainer, Valve Stem Seal and valve spring. Before taking out the valves, clean any small pieces of metal from the valve stem grooves and note to which cylinder each valve came from. Wash every valve and toss out any that have been burned, damaged or cracked. Clean the interior of the valve guides by spraying them with a desirable guide cleaner. Measure the valve stems for signs of wear; if wear exceeds 0.051 mm (0.002 inch), you should replace it. Rub the valve stems with an oil and put them into the openings in the cylinder head. When the valves or seats have been reground, check the valve stem's height and change the cylinder head if the valve is too long. Start by updating the valve guides and after that put in the valve springs and their retainers. Use the adapter 6716A and the Valve Spring Compressor Tool MD-998772A to hold the valve springs, install the locks and then release the tool. Should the valves or seats be ground, find the spring height using a vernier caliper from where the springs rest in the cylinder head to the bottom of the retainer. If the spring height is higher than 42.86 mm (1-11/16 inches), insert a 1.587 mm (1/16 inch) spacer in the head counterbore and the spring should drop back to 41.27 to 42.86 mm (1-5/8 to 1-11/16 inch). After that, install the cylinder head.