JeepParts

My Garage

My Account

Cart

OEM Jeep Lash Adjuster

Lash Adjuster Lifter- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

23 Lash Adjusters found

Jeep Valve Lifters Part Number: 5184332AA

$12.76 MSRP: $18.40You Save: $5.64 (31%)Product Specifications- Other Name: Tappet - Valve Lash; Engine Valve Lifter; Valve Lifter; Adjuster Valve Lash Exhaust; Adjuster Valve Lash Intake; Adjuster Valve Lash

Jeep Valve Lifters Part Number: 5047883AC

$17.67 MSRP: $26.50You Save: $8.83 (34%)Product Specifications- Other Name: Tappet - Valve Lash; Valve Lifter; Adjuster Valve Lash Intake Valve; Adjuster Valve Lash Intake; Adjuster Valve Lash

- Replaces: 5047883AB

Jeep Valve Seals Part Number: 53021894AA

$42.47 MSRP: $62.10You Save: $19.63 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tappet - Valve Lash; Engine Valve Lifter; Valve Lifter; Valve Lifters; Camshaft; Adjuster Valve Lash 6 Per Cylinder Head; Adjuster Valve Lash

- Replaces: 68045795AA

Jeep Valve Lifters Part Number: 53010574AB

$35.15 MSRP: $51.00You Save: $15.85 (32%)Product Specifications- Other Name: Tappet - Valve; Lifter; Tappet Valve

- Replaces: 53010574AA

Jeep Valve Lifters Part Number: 4777976AA

$29.19 MSRP: $37.90You Save: $8.71 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tappet - Valve Lash; Valve Lifter; Adjuster Valve Lash

Jeep Valve Lifters Part Number: 4884594AB

$4.45 MSRP: $6.70You Save: $2.25 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tappet - Valve; Valve Lifter; Tappet; Tappet Valve Solid Bucket Tappets Thickness Is Stamped On Inside Of Bucket.; Tappet Valve See Note

Jeep Tappet Part Number: 4884594AN

$4.45 MSRP: $6.70You Save: $2.25 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tappet - Valve; Tappet Valve Solid Bucket Tappets Thickness Is Stamped On Inside Of Bucket.; Tappet Valve See Note

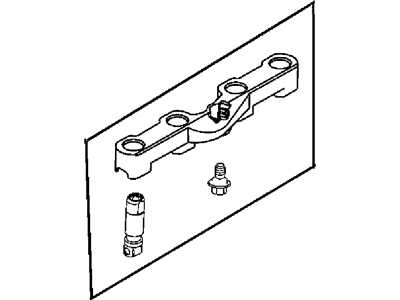

Jeep Valve Lifters Part Number: 5038786AD

$262.30 MSRP: $350.00You Save: $87.70 (26%)Product Specifications- Other Name: Tappet - Hydraulic; Valve Lifter; Yoke; Lifters And Yoke Hydraulic Engine

- Replaces: 5038685AA, 68060715AA, 53021728AE, 53021728AD, 5038786AC, 53021728BC, 53021728BB, 53021728AF, 5038786AA, 5038786AB

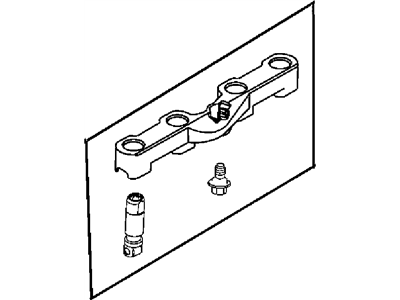

Jeep Valve Lifters Part Number: 5038785AD

$236.80 MSRP: $350.00You Save: $113.20 (33%)Product Specifications- Other Name: Tappet - Hydraulic; Valve Lifter; Yoke; Lifters And Yoke Hydraulic Engine

- Replaces: 53021726AF, 5038684AA, 53021726BB, 53021726BC, 68060714AA, 53021726AE, 5038785AC, 5038785AA, 5038785AB, 53021726AD

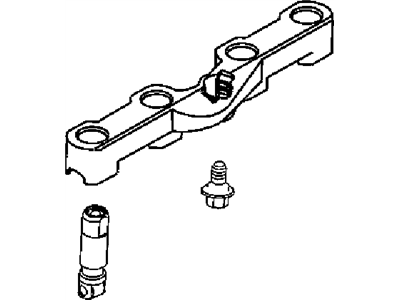

Jeep Valve Lifters Part Number: 5038784AD

$152.73 MSRP: $229.00You Save: $76.27 (34%)Product Specifications- Other Name: Tappet - Hydraulic; Valve Lifter; Yoke; Lifters And Yoke Hydraulic Engine

- Replaces: 53021720AD, 5038784AA, 5038784AC, 53021720AE, 5038784AB, 53021720AB, 53021720AC, 5038686AA

Jeep Valve Spring Retainers Part Number: 68440259AA

$5.47 MSRP: $8.15You Save: $2.68 (33%)Product Specifications- Other Name: Retainer - Valve Spring; Retainer Valve Spring

Jeep Valve Lifters Part Number: 5175440AA

$17.94 MSRP: $23.10You Save: $5.16 (23%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve Lash; Engine Camshaft Follower; Engine Valve Lifter; Rocker/ Tappet; Valve Lifter; Adjuster Valve Lash

Jeep Valve Lifters Part Number: 4621938AB

$41.37 MSRP: $58.60You Save: $17.23 (30%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tappet - Valve; Valve Lifter

- Replaces: 4621938

Jeep Valve Lifters Part Number: 68440310AA

$20.69 MSRP: $30.60You Save: $9.91 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tappet - Valve; Tappet Valve

Jeep Valve Spring Retainers Part Number: 68439892AA

$1.54 MSRP: $2.30You Save: $0.76 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Retainer - Valve Spring; Retainer Valve Spring

Jeep Valve Spring Retainers Part Number: 5093892AA

$2.51 MSRP: $3.75You Save: $1.24 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tappet - Valve Spring; Valve Spring Retainer; Retainer Valve Spring Lower; Retainer Valve Spring Upper; Retainer Valve Spring

Jeep Valve Lifters Part Number: 68249809AA

$43.95 MSRP: $64.70You Save: $20.75 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tappet - Valve; Tappet Valve

- Replaces: 4892686AA

Jeep Valve Lifters Part Number: 4713439

Product Specifications- Other Name: Tappet Package - Valve; Engine Valve Lifter; Valve Lifter; Tappet, Valve - Standard; Tappet Package Valve; Tappet, Valve Lifter; Tappet, Valve

Jeep Valve Lifters Part Number: 5047979AA

Product Specifications- Other Name: Tappet - Valve Lash

Jeep Valve Lifters Part Number: 4892465AB

Product Specifications- Other Name: Tappet - Valve

- Replaces: 4892465AA

| Page 1 of 2 |Next >

1-20 of 23 Results

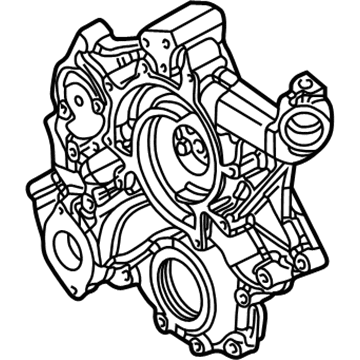

Jeep Lash Adjuster

OEM parts sourced directly from Jeep deliver superior quality, long lasting strength, and a precise fit you can trust. Each item goes through strict quality checks to ensure safety, toughness, and performance that matches your factory equipment. At JeepPartsDeal online shop, you'll get top-quality, budget-friendly OEM Jeep Lash Adjuster for your vehicle. We focus on giving you a high standard without pushing up the price. Our full selection of genuine factory products comes backed by the original manufacturer's warranty. You'll love our fast delivery, seamless shopping experience, and convenient return policy, saving you all the hassle.

Jeep Lash Adjuster ensures valve lash tight and eliminates the sound of ticks and maintains the power on any trail. The history of Jeep has been battlefield to mall parking lots but the brand still values honest steel, short overhangs, a seven slot grin, and matches that go anywhere attitude with selectable drive modes, skid plates, smart diffs, and dashboards answering spoken instructions. Jeep owners are all popping doors and folding windshields and then heading down the ruts, eating the lesser rigs, and exchanging advice on tire pressure and placing their confidence in big axles, high ride and a fraternity that waves at every passing convoy. The voice assistants switch playlists without leaving the wheel, the air updates drop new trail maps overnight, Selec-Terrain dials offer newcomers the ability to switch snow to sand faster than the coffee cools, and the mix of legacy grit and modern-day technology is found in the fact that inside every modern cylinder head, there is a Lash Adjuster where pressurized oil can clean the complete wheel, and erase clearance so that cam lobes can strike against a valve without marking it. Gaps trimmed in milliseconds, and horsepower leakage that difficult washboard roads or heavy cargo would expose, are prevented as revs increase the Lash Adjuster pumps faster. Jeep engines depend on this Lash Adjuster to protect longevity because constant self tuning prevents and eliminates the hammering of metals and the inconvenience of checking the shims periodically. When oil turns frosty as at sunrise to steamy noon the Lash Adjuster changes immediately, using less fuel and allowing Jeep drivers to pursue longer routes without fear of valve chatter.

Jeep Lash Adjuster Parts and Q&A

- Q: What Role Does the Lash Adjuster Play in Fixing a Noisy Valve Lifter in a Four-Cylinder Engine on Jeep Cherokee?A:A noisy valve lash adjuster can be isolated when the engine is idling. Place a length of hose or tubing on the rocker arm cover near the position of each valve while listening at the other end. Or remove the rocker arm cover and, with the engine idling, place a finger on each of the valve spring retainers, one at a time. If a valve lash adjuster is defective, it'll be evident from the shock felt at the retainer as the valve opens. The most likely cause of a noisy valve lash adjuster is a piece of dirt trapped between the plunger and the adjuster body. Remove the rocker arm cover. Remove both rocker arms and both pushrods at the cylinder with the noisy lash adjuster. Remove the adjusters through the pushrod openings in the cylinder head. A special removal tool is available, but isn't always necessary. On newer engines without a lot of varnish buildup, adjusters can often be removed with a magnet attached to a long handle. Store the adjusters in a clearly labeled box to insure their reinstallation in the same adjuster bores. Clean the adjusters with solvent and dry them thoroughly. Do this one adjuster at a time to avoid mixing them up. Check each adjuster wall, pushrod seat and foot for scuffing, score marks and uneven wear. Each adjuster foot must be slightly convex, although this can be difficult to determine by eye. If the base of the adjuster is concave or rough, the adjusters and camshaft must be replaced. If the adjuster walls are damaged or worn, inspect the adjuster bore in the engine block as well. If the pushrod seats are worn, check the pushrod ends. If new adjusters are being installed, a new camshaft must also be installed. If a new camshaft is installed, then use new adjusters as well. Never install used adjusters unless the original camshaft is used and the adjusters can be installed in their original locations! The used adjusters must be installed in their original bores. Coat them with moly-base grease or engine assembly lube. Lubricate the bearing surfaces of the adjuster bores with engine oil. Install the adjuster(s) in the adjuster bore(s). Install the pushrods and rocker arms. Tighten the rocker arm capscrews to the specified torque. Install the rocker arm cover.

- Q: What Role Does the Lash Adjuster Play in Isolating and Addressing Noisy Valve Lifters in a 2.5L Four Cylinder Engine on Jeep Wrangler?A:A noisy valve lash adjuster can be isolated when the engine is idling by placing a length of hose or tubing on the valve cover near each valve while listening at the other end, or by removing the valve cover and placing a finger on each valve spring retainer one at a time; a defective valve lash adjuster will be evident from the shock felt at the retainer as the valve opens. The most likely cause of a noisy valve lash adjuster is dirt trapped between the plunger and the lash adjuster body. To address this, remove the valve cover, then take out both rocker arms and pushrods at the cylinder with the noisy lash adjuster, followed by removing the lash adjusters through the pushrod openings in the cylinder head; a special removal tool is available but may not always be necessary, as lash adjusters on newer engines without significant varnish buildup can often be removed with a magnet attached to a long handle. Store the lash adjusters in a clearly labeled box to ensure their reinstallation in the same bores, keeping them in order if more than one is removed. Clean the lash adjusters with solvent and dry them thoroughly, checking each lash adjuster wall, pushrod seat, and foot for scuffing, score marks, and uneven wear; the foot of each lash adjuster should be slightly convex, and if any lash adjuster is worn concave, scratched, or galled, replace the entire set. If new lash adjusters are being installed, a new camshaft must also be installed, and used lash adjusters should only be installed with the original camshaft in their original locations. When reinstalling, the used lash adjusters must go back into their original bores, coated with moly-base grease or engine assembly lube, and the bearing surfaces of the lash adjuster bores should be lubricated with engine oil before installing the lash adjusters, followed by the pushrods and rocker arms, tightening the rocker arm cap screws to the specified torque, and finally reinstalling the valve cover.