JeepParts

My Garage

My Account

Cart

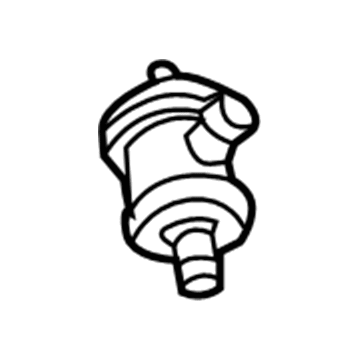

OEM Jeep Wrangler Fuel Tank Vent Valve

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Fuel Tank Vent Valve found

Jeep Wrangler Fuel Tank Vent Valve Part Number: J5360058

Jeep Wrangler Fuel Tank Vent Valve

Choose OEM Fuel Tank Vent Valve that meet Jeep factory standards. Jeep designs and tests every component for precision and durability. Each Fuel Tank Vent Valve follows strict manufacturing steps to lock in quality and fit. If your Jeep Wrangler matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Wrangler parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Jeep Wrangler Fuel Tank Vent Valve is what is required to keep one of the most difficult off road angels running lean and clean. The Jeep Wrangler features have a body on frame construction, coil spring suspension to bring about smooth articulation, solid axles to ensure unbeatable traction, and 8 speed automatic that gives a steady torque as it ascends the rocky mountains or highway. The owners have confidence in the Jeep to be reliable with the bad Wrangler featuring removable doors and roof panels making every journey an open air adventure. Fording seals, skid plates and wide ground clearance allow the Wrangler to crawl across mud and snow and new hybrid 4xe technology indicates that Jeep is committed to being greener without forfeiting trail capabilities. The Wrangler Fuel Tank Vent Valve is in the EVAP system and regulates the vapor flow out of the tank to charcoal canister. The Fuel Tank Vent Valve saves seals, prevents the odor of raw fuel and ensures that the emissions are not high enough to make the Jeep illegal in any road. There is also rugged housing and OE grade seals that allow the Fuel Tank Vent Valve to withstand the harsh temperatures, dust, and vibration, which destroys lesser quality parts. Installation of a new Fuel Tank Vent Valve: this involves parking in a safe place, disconnecting the battery, releasing vapor out of the tank, unclipping the lines, replacing the valve, installing the fasteners, wiring, clearing the codes, ensuring the valve is firmly seated and the area does not hiss.