JeepParts

My Garage

My Account

Cart

OEM 2003 Dodge Dakota Fuel Rail

Engine Fuel Rail- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Fuel Rails found

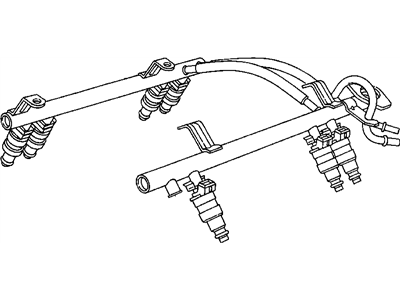

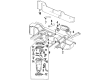

2003 Dodge Dakota Fuel Rail Part Number: 53030848AC

Product Specifications- Other Name: Rail - Fuel; Rail Fuel

- Replaces: 53030848AB

- Item Weight: 5.60 Pounds

- Item Dimensions: 21.7 x 21.1 x 8.6 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53030848AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

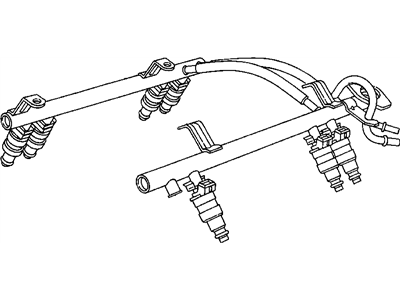

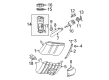

2003 Dodge Dakota Fuel Rail Part Number: 53030598AC

Product Specifications- Other Name: Rail - Fuel

- Replaces: 53030598AB

- Item Weight: 0.60 Pounds

- Item Dimensions: 23.1 x 6.6 x 6.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53030598AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

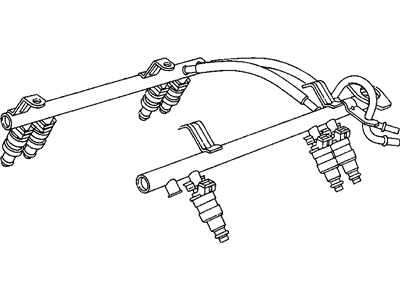

2003 Dodge Dakota Fuel Rail Part Number: 53030593AB

Product Specifications- Other Name: Rail - Fuel; Rail Fuel

- Item Weight: 1.70 Pounds

- Item Dimensions: 11.7 x 11.6 x 3.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53030593AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2003 Dodge Dakota Fuel Rail Parts and Q&A

- Q: How to Service the Fuel Rail and Ensure Proper Fuel System Pressure Release on 2003 Dodge Dakota?A: Fuel damper servicing is not needed and be sure to release the pressure on the fuel system before servicing the fuel rail, as it is always pressurized. First, open the unlocked fuel tank filler tube cap and complete the Fuel System Pressure Release Procedure. Break the negative battery cable connection and take out the air tube on top of the throttle body, as some models require you to also take out the air cleaner ducts too. Remove the connectors from the injector harness at every injector and tag them all for identification. Undo the fastener that holds the fuel supply line and connects it to the fuel rail, disconnect the throttle linkage, speed control linkage and automatic transmission cable from the throttle body if the car has these. After removing the routing bracket and securing nut, wipe away any dirt from each fuel injector close to the fuel rail assembly. Loosen the screws in the fuel rail mount and gently shake the rail to free all of the fuel injectors from the intake manifold. Before removing the fuel rail on these engines, make sure you release the fuel pressure and don't bend or kink the connecting hose during the process. Take out the plugs from the eight fuel injectors and copy the wire labels at each connector. Disconnect the sensor's electrical connector at the intake manifold air temperature sensor on the 3.9L engine without taking it out. Remove the throttle body and A/C compressor support bracket if it is there and then clean the injector holes at the intake manifold. After that, add a little clean engine oil to each injector O-ring to assist fitting during reinstallation. Put the tips of all fuel injectors in the matching injector bores and make sure they are secure. Apply a nut and bolt torque of 11 ± 3 N.m (100 ± 25 in.lbs.) to the fuel rail mounting bolts and attach the crankshaft sensor wiring harness to the fuel rail mounting stud. Link the tagged injector harness cables, fuel line and latch clip with the fuel rail and if a protective cap is there, install it over the test port fitting. After installing the cable routing bracket, throttle cable, speed control cable and automatic transmission cable at the throttle body, add the air tube to the top of the throttle body. Once you're done, close the fuel tank, attach the negative battery cable, start the engine and watch out for fuel leaking.