JeepParts

My Garage

My Account

Cart

OEM 2006 Dodge Dakota Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Crankshafts found

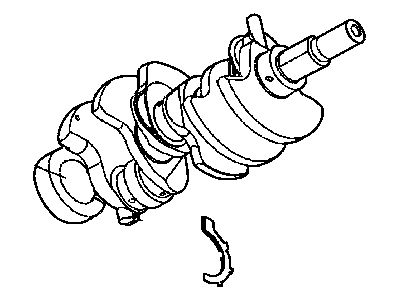

2006 Dodge Dakota Crankshaft Part Number: 53020959AB

$629.85 MSRP: $959.00You Save: $329.15 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Crankshft; Crankshaft See Note

- Item Weight: 48.20 Pounds

- Item Dimensions: 28.4 x 10.1 x 8.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53020959AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

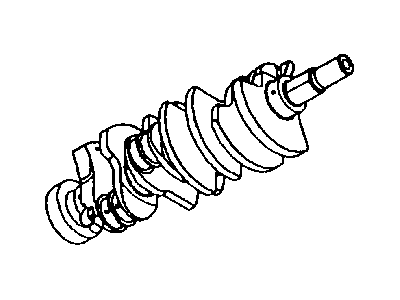

2006 Dodge Dakota Crankshaft Part Number: 53021387AA

Product Specifications- Other Name: Crankshft

- Item Weight: 59.60 Pounds

- Item Dimensions: 30.6 x 9.3 x 7.9 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53021387AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

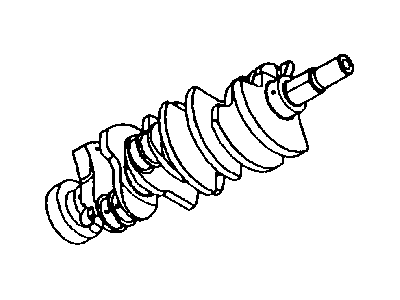

2006 Dodge Dakota Crankshaft Part Number: 53021407AB

Product Specifications- Other Name: Crankshft

- Item Weight: 44.50 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53021407AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2006 Dodge Dakota Crankshaft Parts and Q&A

- Q: How is the Crankshaft Removed from an Engine on 2006 Dodge Dakota?A: Before you remove the crankshaft, remove the engine from the vehicle and also remove the engine's oil pump. Avoid tampering with the oil pan gasket; every time an oil pan is removed, it must be removed from the three locations attached to the block. Next up, take the mounting bolts from the bedplate off and remember the location of the stud bolts to put back later. Next, remove the connecting rods from the crankshaft, keeping care so the critical sealing area on the cylinder block and bedplate is not damaged. The bedplate that supports the lower end of the bearing halves should be treated with care so that you do not drop or damage the bearings inadvertently, because incorrect assembly might seriously harm the crankshaft. Raise the starter motor on its cast pry point to remove the bedplate and use care not to harm the bearing surfaces of the crank while you remove it. If there are deep scratches, signs of blueing or any scoring seen in the rod or main bearing bores, further disassembly might be needed. If corrosion happens in connecting rod bearing bores, it is necessary to remove the cylinder heads to check and repair the pistons and rods; however, if corrosion damages one of the main bearing bores in the bedplate or cylinder block, a whole replacement of the engine is required. If the main bearing halves need to be removed from the block and bedplate, clean the sealing surfaces and bores in the main bearing, plus inspect the bedplate's main bearing bores for damage that will require replacing the engine. If the crankshaft thrust washers are damaged, showing any type of scoring, scratches, signs of wear or blueing on their surface or if the oil pan gasket shows splits, tears or cracks, these parts should be replaced. Make sure to install the crankshaft with main bearings that are a close fit and don't damage the bearings during installation. First, lubricate the tone wheel holdings with sealant, cover the main bearing halves on top with clean oil and then place the crank in the cylinder block. Add the thrust washers and apply Mopar Engine RTV sealant to the bedplate to cylinder block mating surface to keep oil leaks shallow. Clean the areas you are sealing first, then put a 2.5 mm bead of Mopar Engine RTV along the sealing surface. Clean engine oil should be applied to the crankshaft main bearings and to the bedplate's bolt holes before setting the bedplate on the engine block. Place the bolts from the bedplate retainer into each stud location and tighten them up to the specified order: first, snug the bolts that won't contact the block, then set the next bolts to 54 Nm (40 ft. lbs.) and those next to 7 Nm (5 ft. lbs.), turn an additional 90° and then tighten bolts A - E to 27 Nm (20 ft. lbs.). First, measure the end play of the crankshaft, then put in the connecting rods and measure the side clearance, install the oil pump and finally place the engine back into position.