JeepParts

My Garage

My Account

Cart

OEM 2007 Dodge Caliber Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Crankshafts found

2007 Dodge Caliber Crankshaft Part Number: 68001692AC

Product Specifications- Other Name: Crankshaft - Engine

- Replaces: 4884742AB, 68001692AA

- Item Weight: 50.00 Pounds

- Item Dimensions: 28.6 x 8.2 x 8.4 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68001692AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2007 Dodge Caliber Crankshaft Part Number: 68001694AC

Product Specifications- Other Name: Crankshaft - Engine; Crankshaft Kit Engine See Note; Crankshaft Package Engine; Crankshaft Kit Engine

- Replaces: 68001694AA, 4884563AC

- Item Weight: 44.60 Pounds

- Item Dimensions: 21.9 x 8.4 x 7.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68001694AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

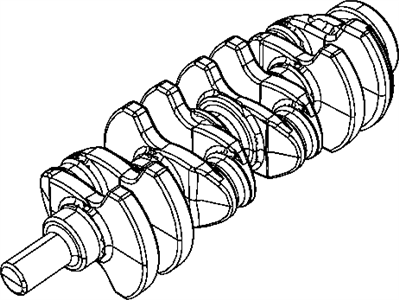

2007 Dodge Caliber Crankshaft Part Number: 68001693AC

Product Specifications- Other Name: Crankshaft - Engine; Crankshaft Package Engine; Crankshaft Kit Engine

- Replaces: 4884561AC, 68001693AA

- Item Weight: 42.70 Pounds

- Item Dimensions: 22.3 x 8.4 x 7.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 68001693AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2007 Dodge Caliber Crankshaft Parts and Q&A

- Q: What Are the Steps Involved in Installing a Crankshaft on 2007 Dodge Caliber?A: Five bearings hold up the crankshaft and the holes in the crankcase above the bearings have oil, but the holes below are plain. Two-piece thrust bearings control crankshaft end play on the number three main bearing journal. Use Mopar brake cleaner on the holes of the main bearing cap bolt, then blow them out with compressed air. Set the upper bearing shells in the engine block with their lubrication grooves and oil holes lined up so that the oil holes are aligned and the tabs fit properly. If the crankshaft has had machine work done, it should be balanced with its target ring in place. Spray the Mopar brake parts cleaner onto the crankshaft and target ring and wipe with compressed air to get rid of oil and dirt. When using new mounting screws for the target ring, go in the order from #1 to #7 and tighten them to 13 Nm with a T30 torx bit. Apply just a small amount of trans gel to the thrust bearings and have the notches face the crankshaft before installing. Install the thrust bearings into the block and be sure not to get oil on the area that will mate with the ladder frame. Spray some oil inside the bearings and journals before you place the crankshaft in the engine block. Fit the lower main bearings into the main bearing cap, with the bearing tabs in place, then mount the bearing caps to the engine block with clean and dry threads. When aligning the bearings, operate the crankshaft until the number 4 piston stops at TDC, then push the crankshaft back and forth to its limits. After that, wedge something between the last part of the cylinder block and the rear crankshaft counterweight to grip it firmly. Apply 27 Nm plus 45° of tightening to the bolts in the proper order, then take away the wedge tool. The crankshaft turning torque should be under 5.6 Nm and you also need to check the crankshaft end play. After that, install the connecting rod bearings and caps, using new bolts and hand-tighten them up to 20 Nm plus 90°. Use the installation manual to install the ladder frame assembly, balance shaft module, crankshaft position sensor and cylinder head that has been removed. Put in the front crankshaft sprocket, timing chain, timing chain front cover, oil pan, both crankshaft oil seals, engine mount support bracket, crankshaft vibration damper and water pump pulley. Following these instructions, move the engine from the repair stand to dolly 6135 and engine support cradle 6710. Safely strap the engine into place. Fit the crankshaft rear oil seal, bolt the drive plate/flex plate in with new screws tightened to 95 Nm, add the transaxle with bellhousing bolts tightened to 101 Nm and install the entire engine unit. After this, change the oil filter, put oil and coolant into the radiator, start the car, watch for leaks and install the cover for the engine.