JeepParts

My Garage

My Account

Cart

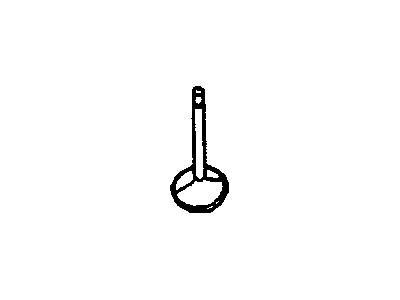

OEM 2007 Dodge Dakota Intake Valve

Engine Intake Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Intake Valve found

2007 Dodge Dakota Intake Valve Part Number: 53020747AB

$46.65 MSRP: $94.55You Save: $47.90 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Valve - Intake; Valves; Valve Intake Standard 3 Per Cylinder Head; Valve Intake Standard

- Item Weight: 0.60 Pounds

- Item Dimensions: 4.8 x 2.2 x 2.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 53020747AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2007 Dodge Dakota Intake Valve Parts and Q&A

- Q: How to Service and Repair Exhaust Valve and Intake Valves on 2007 Dodge Dakota?A: Before working on the valve, first take off the cylinder heads, then the rocker arms and lash adjusters, next the camshaft bearing caps and then the camshaft. Although the procedure is shown for just one valve and valve spring, the same is done to all six valves and springs. Squeeze the valve spring using the Tool C-3422-B or C-3422-C Valve Spring Compressor and Tool 8519 adapter and tap on the valve spring from above to remove the spring retainer locks. Take care when removing the two spring retainer lock halves so that the valve spring doesn't snap up from the compression. After inserting the spring compressor and pulling the old spring, unscrew and remove the spring retainer, then check the keeper grooves below the spring for sharp edges and smooth them with a light file before removing the old valve. As the valve stem seals are the same for intake and exhaust, you need to take them out and carefully mark the valve stem where you plan to reinstall them. In most cases, inspection and testing for reuse should be carried out when the valves are being removed. Test the valve springs by bringing the odd surface of Tool C-647 against the 40.12 mm marker on the threaded stud and the zero marker on the front. Spring the bottom load of the system onto the stud, raise the setting handle and pull on the torque wrench until it pings, keeping note of the reading at that point. Multiply the reading by two to find the spring load that will be present at test length, then see if all the spring height and allowable forces match the guidelines, changing out any parts that do not meet the standard.