JeepParts

My Garage

My Account

Cart

OEM Chrysler Cirrus Power Steering Pump

Power Steering Pump Unit- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Power Steering Pumps found

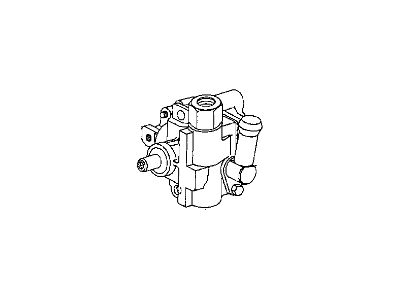

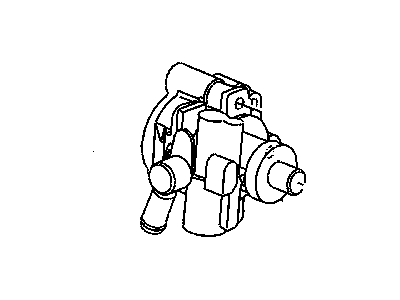

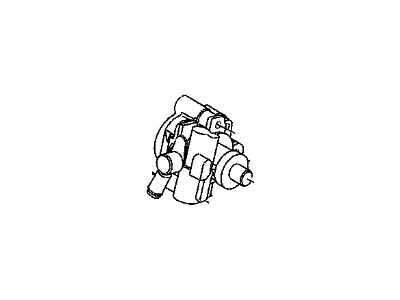

Chrysler Cirrus Power Steering Pump Part Number: R4874243

Chrysler Cirrus Power Steering Pump Part Number: 4656062

Chrysler Cirrus Power Steering Pump Part Number: 4656034

Chrysler Cirrus Power Steering Pump

Choose OEM Power Steering Pump that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Power Steering Pump follows strict manufacturing steps to lock in quality and fit. If your Chrysler Cirrus matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Cirrus parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Power Steering Pump in Chrysler Cirrus deals with hydraulic power steering well understood as the part of the engine that transforms energy to hydraulic power assists in steering operations done by a driver. The pump delivers hydraulic power to the steering system; it makes it easier to turn the steering wheel thus assists the drivers to maneuver their vehicles. The high-performance pump is operated by the engine and coupled to the system of steering through the high-pressure hydraulic hoses; the steering will then be recipient of power assist in the direction of the turn whenever there is a rotation of the steering wheel. Problems arising from the power steering pump include fluid leakage, noise, no power assistance, and sensitivity that should be detected and rectified correctly through assessment. In summary, power steering pump can be seen to contribute significantly for development of the control feel of the Chrysler Cirrus vehicle along with comfort of the driver while steering.

Chrysler Cirrus Power Steering Pump Parts and Q&A

- Q: How to Service and Repair a Power Steering Pump on Chrysler Cirrus?A:Always be sure the engine is not running and check the power steering pump's fluid before you work on it, using Mopar Power Steering Fluid and not automatic transmission fluid. Remove any dirt from the filler cap and review the dipstick to confirm that the level is FULL COLD once the vehicle's fluid temperature is 21 - 27 °C (70 - 80 °F). Bring the pump fluid reservoir to the proper height and let the fluid sit in there for two minutes. Let the engine run for some time and then switch it off. Should it be required, top up the fluids and run the engine until the level doesn't move while it's running. Pump up the front end, start the vehicle and slightly turn the Steering Wheel right and left, briefly reaching the wheel stops, adding power steering fluid as you see fit. Reduce the car's height and steer from one lock position to the other. Turn the engine off, check the level of fluid and replenish it as needed. If the reading is very foamy, wait a while and try again.

- Q: How to Remove and Install a Power Steering Pump on Chrysler Cirrus?A:Power steering pumps on vehicles are designed to be either constant flow rate or variable flow rate, based on their tubes; the standard tube nut is used in the first and the second features a banjo type fitting. To begin, unhook the battery cable from the negative post and set it aside and then drain most of the fluid out of the remote reservoir. Position the vehicle off the ground, take off the right front tire and wheel and detach the accessory drive splash shield. Separate the hose that carries pressure-forced steering fluid from the pump and let the fluid empty while you cap both ends of the hose and pump. Unfasten the clamp on the power steering fluid supply hose and put a cap on the suction fitting. Unscrew the heat shield on the antilock brakes hydraulic control unit, then remove the front attaching bolt of the power steering pump from the accessory drive bracket, before working on the bolt at the pump's back. Pull the wheel speed sensor cable from its connection in the wiring harness and take out the sealing grommet. If your vehicle is missing antilock brakes, you must take out the routing hole's sealing plug. You should reach the front bracket's top bolt by pulling the extension tool through the routing hole for the wheel speed sensor along with a 15 mm flex socket. Take out the Drive Belt and remove the power steering pump and its bracket from the engine, setting them on the antilock brakes hydraulic control unit. If you are using a different pump, remove the bracket from the engine and take any needed parts over to the new pump. To put everything in place for installation, put the power steering pump and mounting bracket onto the antilock brakes hydraulic control unit first, before you position the pump. Secure the mounting bracket on the engine at the rear with bolts that have been tightened to 54 Nm (40 ft. lbs.), then loosely put the bolts into place for the pump and front bracket. Wipe all open ends and connectors of Power Steering Hoses with a lint-free cloth. Should the car lack variable-assist power steering, put a new O-ring around the power steering pressure hose and pump some fresh fluid into it. On vehicles with variable-assist steering, attach a copper washer on each banjo side and install the flow bolt loosely. Fit the power steering pressure hose onto the pump and only tighten the tube nut halfway. Fit the power steering pump drive bolt, next use a 1/2 inch breaker bar to tighten the bottom two adjusting bolt slots and the top bolt to 54 Nm (40 ft. lbs.). Position the pressure hose so that it doesn't contact the pump pulley or drive belt, then fasten the tube nut to 31 Nm (275 inch lbs.) for standard fittings or the banjo fitting bolt to 47 Nm (35 ft. lbs.) for banjo fittings. Following this, add the power steering fluid supply hose and the clamp, set the heat shield in place, route the wheel speed sensor cable and join it to the car's wiring harness. If your car has antilock brakes, install the sealing grommet and retainer. If it doesn't, use the sealing plug. Add the accessory drive splash shield, wheel and tire, then tighten the lug nuts to a torque of 129 Nm (95 ft. lbs.), as recommended. Drive the vehicle down, reattach the negative battery cable, ensure the Power Steering Reservoir is filled correctly, order the Power Steering Pump Initial Operation service and check for leaks. You should only use Mopar Power Steering Fluid instead of automatic transmission fluid.