JeepParts

My Garage

My Account

Cart

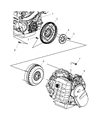

OEM Chrysler Torque Converter

Transmission Torque Converter- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

25 Torque Converters found

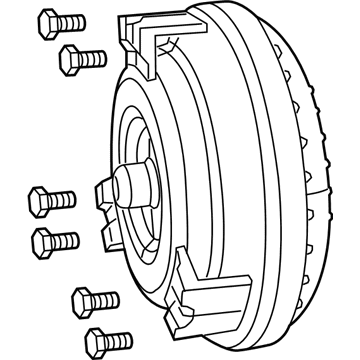

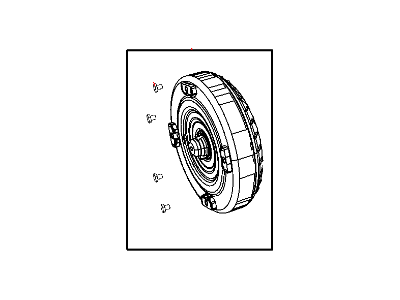

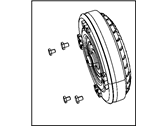

Chrysler Torque Converter Part Number: RL078840AA

$456.48 MSRP: $530.00You Save: $73.52 (14%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Converter - Torque; Converter; Converter Kit Torque

- Replaces: 68078840AA

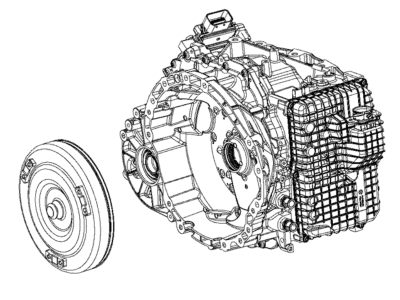

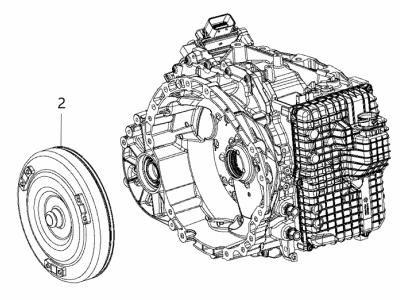

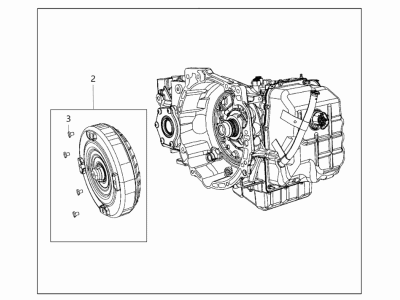

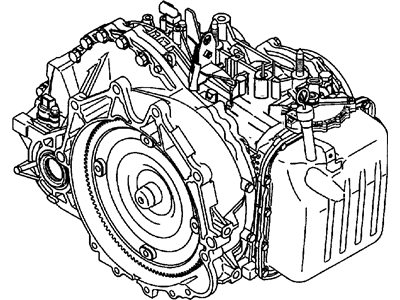

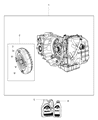

Chrysler Transmission Part Number: 68429317AA

$4583.55 MSRP: $5480.00You Save: $896.45 (17%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Package Part - With Torque Converter; Transmission With Torque Converter

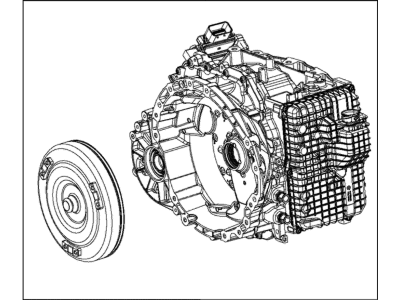

Chrysler Transmission Part Number: 68311996BA

$6163.70 MSRP: $7385.00You Save: $1221.30 (17%)Ships in 1 Business DayProduct Specifications- Other Name: Package Part - With Torque Converter; Transmission With Torque Converter

- Replaces: 68311996AA, RL311996AA, RL311996BA

Chrysler Torque Converter Part Number: RL087442AA

$929.20 MSRP: $1125.00You Save: $195.80 (18%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Converter - Converter Kit; Automatic Transmission Torque Converter; Converter

- Replaces: 68087442AA

Chrysler Transmission Part Number: 68429316AA

$4587.65 MSRP: $5290.00You Save: $702.35 (14%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Package Part - With Torque Converter; Transmission With Torque Converter

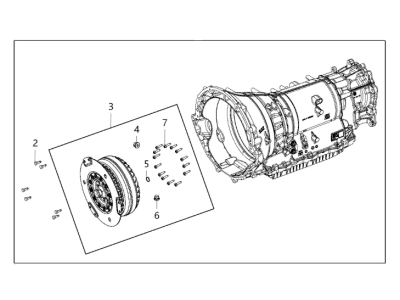

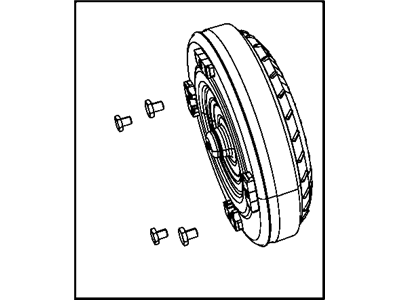

Chrysler Torque Converter Part Number: RL404379AA

$810.80 MSRP: $974.00You Save: $163.20 (17%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Converter - Torque; Automatic Transmission Torque Converter; Converter; Converter Kit Torque Includes Bolt Item #3; Converter Kit Torque

- Replaces: 68404379AA

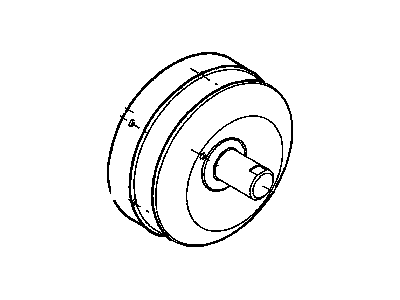

Chrysler Torque Converter Part Number: R4778031AC

$319.74 MSRP: $377.00You Save: $57.26 (16%)Ships in 1 Business DayProduct Specifications- Other Name: Converter - Torque; Converter Kit Torque; Converter Torque

- Replaces: 4797544AB, 5018956AB, RL018956AC, 5018956AC, 4778031AB, R4797544AC, RX018956AC, R4778031AB, R4797544AB

Chrysler Torque Converter Part Number: RL147484AD

$2602.98 MSRP: $3010.00You Save: $407.02 (14%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Transmission Kit - With Torque Converter; Transmission

Chrysler Transmission Part Number: 68166504AD

$6859.20 MSRP: $7360.00You Save: $500.80 (7%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Package Part - With Torque Converter; Transmission With Torque Converter

- Replaces: RL166504AD, RL166504AC, 68166504AC

Chrysler Torque Converter Part Number: RL261258AA

$960.47 MSRP: $1120.00You Save: $159.53 (15%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Converter - Torque; Automatic Transmission Torque Converter; Converter; Converter Kit Torque

Chrysler Converter Part Number: RL087445AA

$971.71 MSRP: $980.00You Save: $8.29 (1%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Converter - Torque; Automatic Transmission Torque Converter; Converter Kit Torque

- Replaces: 68087445AA

Chrysler Torque Converter Part Number: R8036990AD

$171.32 MSRP: $202.00You Save: $30.68 (16%)Product Specifications- Other Name: Converter Kit - Torque; Converter Kit Torque

- Replaces: R8036990AC

Chrysler Torque Converter Part Number: RL070538AB

$212.84 MSRP: $310.00You Save: $97.16 (32%)Product Specifications- Other Name: Converter Kit - Torque; Converter Kit Torque

- Replaces: 68070538AB

Chrysler Torque Converter Part Number: RL234051AA

$342.97 MSRP: $483.00You Save: $140.03 (29%)Product Specifications- Other Name: Converter - Torque; Automatic Transmission Torque Converter; Converter; Converter Kit Torque Includes Item #3; Converter Kit Torque

- Replaces: 68234051AA, 68234039AA

Chrysler Transaxle Part Number: RL090720AD

$5362.43 MSRP: $6225.00You Save: $862.57 (14%)Product Specifications- Other Name: Transmission - With Torque Converter; Transmission Kit With Torque Converter

Chrysler Transmission Part Number: RL367522AA

$4078.13 MSRP: $4700.00You Save: $621.87 (14%)Product Specifications- Other Name: Package Part - With Torque Converter; Transmission With Torque Converter

- Replaces: 68367522AA

Chrysler Torque Converter Part Number: R5093926AE

$586.46 MSRP: $684.00You Save: $97.54 (15%)Product Specifications- Other Name: Converter - Torque; Converter Kit Torque

- Replaces: RL093926AE, 5093926AE, 5093926AC, R5093926AC, 5093926AD, 68006834AA

Chrysler Torque Converter Part Number: R5093888AE

$346.53 MSRP: $407.00You Save: $60.47 (15%)Product Specifications- Other Name: Converter - Converter Kit

- Replaces: 5093888AC, 68006802AA, 5093888AB, RL093888AE, 5093888AD, 5093888AE

Chrysler Transmission Part Number: R8283310AA

$3723.18 MSRP: $4290.00You Save: $566.82 (14%)Product Specifications- Other Name: Package Part - With Torque Converter; Transmission With Torque Converter

- Replaces: 68267521AC, 68267521AD, RL267521AC, RL267521AD

Chrysler Transaxle Part Number: MD978460

Product Specifications- Other Name: Converter - With Torque Converter; Transaxle Packing W/Torque Converter; Transmission With Torque Converter

| Page 1 of 2 |Next >

1-20 of 25 Results

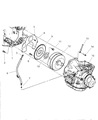

Chrysler Torque Converter

OEM parts sourced directly from Chrysler deliver superior quality, long lasting strength, and a precise fit you can trust. Each item goes through strict quality checks to ensure safety, toughness, and performance that matches your factory equipment. At JeepPartsDeal online shop, you'll get top-quality, budget-friendly OEM Chrysler Torque Converter for your vehicle. We focus on giving you a high standard without pushing up the price. Our full selection of genuine factory products comes backed by the original manufacturer's warranty. You'll love our fast delivery, seamless shopping experience, and convenient return policy, saving you all the hassle.

Chrysler Torque Converter pumps engine muscle into action, providing it with swift starts and fuel-friendly cruising. Chrysler vehicles changed in solidness to the current cabins that suppress sound and absorb shocks. The breakthrough minivan, which was a family hauler, demonstrated that spacious seating and easy access can be done with smart pricing. The swept body lines, inspired by the Airflow experiment, cut along the wind so the occupants will feel stable and save pump money. The brand continues to be fascinated by Floating Power mounts, which break shake and then hit the steering wheel through the mounting. Chrysler has managed to maintain a balance between fashion, interior size, and utility such that a driver can slip in, hit the start button, and just enjoy the ride. Within each automatic gearbox, there is a Torque Converter that rotates a pump and turbine in a fluid bath to boost the torque during takeoff and ensure the engines are pleased when the car comes to a halt. As the cruising speed approaches constant, the Torque Converter engages the halves of the converter, eliminating loss and forcing additional mileage out of each gallon. The rugged build of the Torque Converter, which shrugs off heat, shudder, and operates on four-cylinder and V6 drives without subjective adjustments, further proves that the device is well-nourished. Drivers have confidence in the Chrysler hardware as the Torque Converter adjusts output based on the load so it can provide assured pulls on hilly headings and easy revolutions on flat roads.

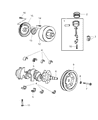

Chrysler Torque Converter Parts and Q&A

- Q: How to Install a Torque Converter on Chrysler Town & Country?A:Before adding the torque converter, check the converter hub and the notches in the drive for sharp or rough areas and if any exist, smooth them out gently with 320/400 grit paper or crocus cloth. Add transmission fluid to the converter hub and oil pump seal lip and put the torque converter on top of the transmission. Try to not harm the oil pump seal or bushing when you are inserting the torque converter into the transmission at the front. Put the torque converter against the opening of the oil pump seal and then insert the hub into the pump. While you keep pushing, turn the converter until you hear it lock into the gears of the oil pump. Weigh the oil pump bolts on a scale with the converter lugs fully installed and check so that the surface of the converter lugs is 1/2 inch further back than the straightedge when fully seated. As an option, hold the converter in place with a C-clamp on the housing. Set the transmission properly in the car and place the suitable fluid inside it.

- Q: How to Service and Repair a Torque Converter on Chrysler Pacifica?A:The first step in servicing and repairing the torque converter is to remove the transmission and housing from the car, putting a suitable drain pan under the housie's end. Always check that the lifting device or work surface is safe before you remove the torque converter, because once it's removed, the unbalanced load can cause the workpiece to move. When you separate the heavy torque converter from the transmission, only remove it once the center hub clears the oil pump seal and moves in front of the plate. Before fitting anything, make sure all edges and scratches on the converter hub and drive notches are polished by sanding with 320/400 grit or crocus cloth if needed to avoid damaging the pump seal. Add transmission fluid to the converter hub and the lip of the oil pump seal. Slide the torque converter into place without harming either seal or bushing. Position the torque converter above the oil pump seal opening, slide the hub into the oil pump and while you push the converter deep into the pump, turn it until it is seated with the gears. Ensure that, when installed, the converter lugs are 1/2 inch behind the straightedge as seen on a scale. Should you need to support the converter at all, first attach a C-clamp to the housing and secure it, then set the transmission into the car and fill it with the correct fluid.