JeepParts

My Garage

My Account

Cart

OEM Dodge Challenger Coil Springs

Strut Spring- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

78 Coil Springs found

Dodge Challenger Coil Spring, Front Part Number: 5181609AB

$95.39 MSRP: $146.00You Save: $50.61 (35%)Ships in 1-2 Business Days

Dodge Challenger Coil Spring, Front Part Number: 5168880AC

$92.49 MSRP: $141.00You Save: $48.51 (35%)Ships in 1-2 Business Days

Dodge Challenger Coil Spring, Rear Part Number: 5168888AC

$102.36 MSRP: $156.00You Save: $53.64 (35%)

Dodge Challenger Coil Spring, Front Part Number: 5168882AB

$64.45 MSRP: $141.00You Save: $76.55 (55%)Ships in 1-2 Business Days

Dodge Challenger Coil Spring, Rear Part Number: 5168953AB

$81.51 MSRP: $126.00You Save: $44.49 (36%)Dodge Challenger Spring, Rear Part Number: 68531419AA

$58.26 MSRP: $87.30You Save: $29.04 (34%)Ships in 1-2 Business DaysDodge Challenger Coil Spring, Front Part Number: 5168881AC

$92.49 MSRP: $141.00You Save: $48.51 (35%)Ships in 1-2 Business DaysDodge Challenger Coil Spring, Rear Part Number: 5181904AC

$96.45 MSRP: $147.00You Save: $50.55 (35%)Ships in 1-2 Business DaysDodge Challenger Coil Spring, Rear Part Number: 5168957AB

$106.59 MSRP: $162.00You Save: $55.41 (35%)Ships in 1-2 Business DaysDodge Challenger Coil Spring, Front Part Number: 68031642AC

$81.95 MSRP: $125.00You Save: $43.05 (35%)Ships in 1-2 Business DaysDodge Challenger Coil Spring, Rear Part Number: 68227199AA

$98.34 MSRP: $150.00You Save: $51.66 (35%)Ships in 1-2 Business DaysDodge Challenger Coil Spring, Rear Part Number: 5168891AB

$103.14 MSRP: $157.00You Save: $53.86 (35%)Ships in 1-2 Business DaysDodge Challenger Coil Spring, Front Part Number: 5168886AB

$99.63 MSRP: $152.00You Save: $52.37 (35%)Ships in 1-2 Business DaysDodge Challenger Coil Spring, Front Part Number: 68240392AA

$86.02 MSRP: $131.00You Save: $44.98 (35%)Ships in 1-2 Business DaysDodge Challenger Coil Spring, Front Part Number: 5168879AC

$92.49 MSRP: $141.00You Save: $48.51 (35%)Ships in 1-2 Business DaysDodge Challenger Coil Spring, Front Part Number: 5168883AC

$99.63 MSRP: $152.00You Save: $52.37 (35%)Ships in 1-2 Business DaysDodge Challenger Coil Spring, Rear Part Number: 5168899AC

$223.20 MSRP: $332.00You Save: $108.80 (33%)Ships in 1-2 Business DaysDodge Challenger Coil Spring, Front Part Number: 5181903AC

$85.91 MSRP: $130.00You Save: $44.09 (34%)Ships in 1-2 Business DaysDodge Challenger Coil Spring, Rear Part Number: 5168954AB

$76.71 MSRP: $116.00You Save: $39.29 (34%)Ships in 1-2 Business DaysDodge Challenger Coil Spring, Front Part Number: 68211291AA

$92.91 MSRP: $140.00You Save: $47.09 (34%)

| Page 1 of 4 |Next >

1-20 of 78 Results

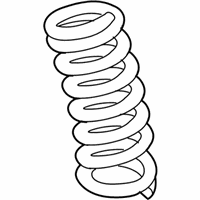

Dodge Challenger Coil Springs

Choose OEM Coil Springs that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Coil Springs follows strict manufacturing steps to lock in quality and fit. If your Dodge Challenger matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Challenger parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

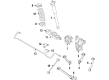

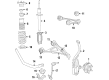

Coil springs which are suspension parts are used in Dodge challenger vehicles to support its weight and to cater for any shocks resulting from an uneven surface. This function assist in reducing passengers from feeling say impacts on the body as to make the vehicle produces less roll. There are two primary types of coil springs used in Dodge Challengers: We noted it elaborative and progressive and at the same constant. In constant coil features, the coils are evenly distributed while in the progressive features the coils are equally distributed at one end while larger at the other end is suitable for vehicles that will be carrying much load. If there is drooping of a Dodge Challenger or such features as uneven tire tread, it is time for a change of coils springs at least one of them. Failure in coil springs can in most cases be spotted through a simple visual inspection of the vehicle and this makes it easy to service it and make the necessary adjustments.

Dodge Challenger Coil Springs Parts and Q&A

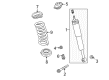

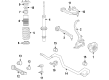

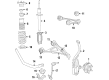

- Q: How to Remove and Replace Rear Suspension Coil Springs on Dodge Challenger?A:You should raise and support the vehicle before replacing the rear suspension coil spring(s). After taking out the wheel mounting nuts, also take off the rear tire and wheel assembly. During servicing of the left Shock Absorber, take out the fuel filler tube. It helps keep the engine strong if you use more jack stands under the engine cradle during the removal and installation of the rear suspension. If dealing with a dual exhaust or if you have access beneath the exhaust on a single side, place a jack or stand below the exhaust end, free the Muffler and resonator hangers and drop the exhaust on top of the jack or stand. After that, put an under-hoist utility jack or transmission jack below the center of the rear axle differential, lift the jack head against the differential and make sure it's secure but not attached to the stabilizer bar. Detach the screws in the shock absorber upper mount and the lower nut and bolt. Do not remove or loosen the crossmember bolts on the other side when you remove the bolts surrounding the transaxle, to ensure that wheel alignment is not necessary. Remove both the front and rear bolts that attach the crossmember on the repair side, but never take out the bolts so far that the crossmember comes in contact with other components. Lower the jack till the repair side's crossmember rests just below the body flange and lift and tilt the shock absorber top downward, so the bottom end comes out of the spring link pocket. Carefully disconnect the brake hose at the bracket that's fastened to the body so as not to overstretch and ruin it. Lower the jack gradually, stopping when the coil spring and isolators are right near the surface, so you won't be lowering the vehicle too much.

- Q: How Are Coil Springs Installed in Rear Suspensions on Dodge Challenger?A:You should start by putting the upper isolator (1) and lower isolator (5) on the ram spring (2) to ensure they fit all the way. After that, slide the coil spring with isolators into the spring link's spring pocket (1), placing the bottom most isolator (2) into the pocket and making sure the top of the spring touches the body mount. Put the lower part of the Shock Absorber into the spring link pocket and tilt the top in to fit into the upper mounting holes. Mount the lower shock to the vehicle and tighten the lower shock bolt and nut at the end; do not secure them at this time. For those with AWD, remember to place the spacers (1) right on top of the crossmember mount bushings (2). Guiding the coil spring and upper part of the shock absorber (4), raise the jack and position them into place, then fix the tops with the upper screws (2) and tighten to 38 ft. lbs. You should not use the shorter mounting bolts from the front in the rear, as the longer rear bolts are needed at that point. Restore the mounting bolts for the crossmembers (2 and 3), but for now, simply snug them so you don't tighten them completely yet. Take a measurement (1) from the tension link (2) to the body welding flange (3) to avoid any interference with suspension movement; make sure it is greater than 12 mm. When the gap is less than 12 mm, shift that rear crossmember bracket to the rear until it meets the required distance, allowing three bolts to loosen and keeping one snugger than the rest, then snug up all the bolts again and check the other side is fine. Turn the crossmember bolts (2 and 3) to a tightness of 180 Nm (133 ft. lbs.) and take the jack away from under the rear axle. When the rear exhaust was lowered before, reposition it to sit as it should and attach the isolators at the Muffler and resonators brackets while lifting the jack holding up the muffler. When everything is in place, install the fuel filler tube and wheel/tire assembly (1). Turn bolts (3) to 150 Nm or 190 Nm (110-140 ft. lbs.) for police officers. Place the car on an alignment rack or drive-on lift and make sure the lift is high enough to reach the lower mounting bolt's position. After that, clamp the lower shock absorber nut (4) using 72 Nm (53 ft. lbs.) of torque.