JeepParts

My Garage

My Account

Cart

OEM Dodge Challenger Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Oil Pans found

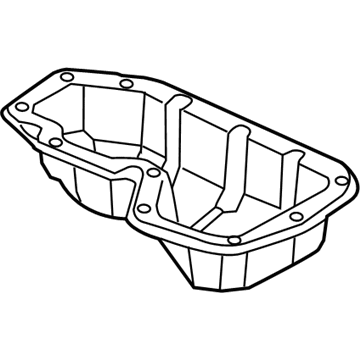

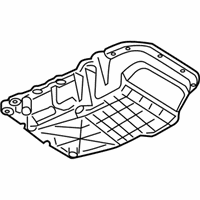

Dodge Challenger Oil Pan Part Number: 68166425AD

$443.11 MSRP: $674.00You Save: $230.89 (35%)

Dodge Challenger Oil Pan Part Number: 5184513AC

$208.47 MSRP: $311.00You Save: $102.53 (33%)

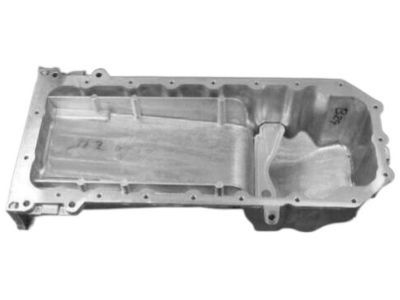

Dodge Challenger Oil Pan Part Number: 53010814AA

$358.39 MSRP: $528.00You Save: $169.61 (33%)Ships in 1-2 Business Days

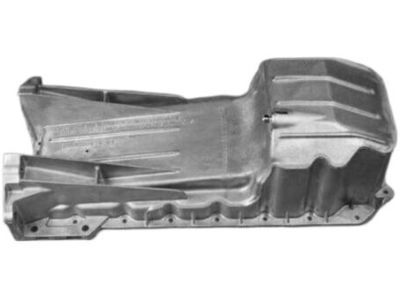

Dodge Challenger Oil Pan Part Number: 5037634AC

$425.94 MSRP: $623.00You Save: $197.06 (32%)Ships in 1-2 Business DaysDodge Challenger Oil Pan Part Number: 4792865AD

$370.98 MSRP: $546.00You Save: $175.02 (33%)Ships in 1-2 Business DaysDodge Challenger Oil Pan, Upper Part Number: 68051599AE

$201.67 MSRP: $301.00You Save: $99.33 (33%)Ships in 1-2 Business DaysDodge Challenger Oil Pan, Lower Part Number: 5184546AD

$159.47 MSRP: $240.00You Save: $80.53 (34%)

Dodge Challenger Oil Pan

Choose OEM Oil Pan that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Oil Pan follows strict manufacturing steps to lock in quality and fit. If your Dodge Challenger matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Challenger parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Oil Pan in Dodge Challenger vehicles On the Dodge Challenger auto are used in the engine oil system because it is used to retain the motor oil that is used to lubricate the different parts of the car's engine to avoid friction. Located right below the engine, the Oil Pan holds oil in reserve once the engine is turned off this helps avoid leakage that may cause huge losses on the engine. During the subsequent years the Dodge Challenger models might have adopted various sort of Oil Pan including wet sump style. These designs may experience problems such as the effect of oil movement particularly during high speed maneuvering which hampers lubrication. On the other hand, some high-performance applications may require specific type, for instance, implementing the dry sump system in which extra pumps supply the necessary constant oil circulation particularly under certain conditions. Altogether, the Oil Pan plays a crucial role in ensuring the efficiency of the car's engine and the general condition of the Dodge Challenger model.

Dodge Challenger Oil Pan Parts and Q&A

- Q: How to Install an Oil Pan on Dodge Challenger?A:It helps to start by cleaning the oil pan and both the oil pump housing and rear seal retainer. Then apply a 1/8 inch line of Mopar(R) Engine RTV GEN II along the parting line between the oil pump housing and the rear seal retainer. After that, place the oil pan gasket (4) inside the block (5), fit the oil pan (1) with both attaching fasteners (2) and (3) firmly by hand and make sure the rear side of the oil pan is perpendicular to the transmission bell housing. Prior to doing other work, pre-check four M10 horizontal rear oil pan to transmission bolts (1) to 1.4 Nm (12 in. lbs.), followed by oil pan alignment bolt (1) to 28 Nm (250 in. lbs.) and bolt (2) to 28 Nm (250 in. lbs.). Screw in the remaining M8 bolts and M8 nuts until they reach 28 Nm (250 in. lbs.) and tighten the three M6 bolts to 12 Nm (105 in. lbs.). Finally, tighten the oil pan to transmission bolts below the engine to 55 Nm (40 ft. lbs.). After that, set the steering gear to cradle bolts by tightening the fasteners to 95 Nm (70 ft. lbs.) Center the gear assembly in its travel before bringing the steering coupling (2) into contact with the input shaft (3). Second, install a new pinch bolt (1) and torque it to 54 Nm (40 ft. lbs.) when fitting the coupling. If an Oil Cooler has been acquired, attach it and tighten the attaching bolt to 61 Nm (45 ft. lbs.). After that, put in the Oil Filter and tighten it to 12 Nm (106 in. lbs.). Lower the vehicle and add the engine oil level indicator tube (2). Place the retaining bolt (1) and tighten it to 12 Nm (105 in. lbs.). After that, fit the generator bracket (4) and bolts (3) and tighten the generator mounting bolt (2) to 65 Nm (48 ft. lbs.) and the generator bracket bolt (3) to 54 Nm (40 ft. lbs.). Pour the proper oil into the engine crankcase, making sure you do not overfill it and attach the negative Battery Cable.

- Q: How to remove an oil pan on Dodge Challenger?A:The first part of replacing the engine oil pan is to disconnect and separate the negative Battery Cable. After that, take out the Intake Manifold and increase the car's height by supporting it. Once you remove the belly pan, drain the engine oil and after that remove the Oil Filter. You should not unhook the Power Steering Hoses, tie rod ends or separate the steering column coupler. After that, remove the bolts from the steering gear mounting bracket and then place the steering gear away from the car. Loosen the nuts under the engine mounts and remove both the engine oil dipstick and the tube from the oil pan. Lift the vehicle lower and install Engine Lift Fixture 8984A, Engine Lift Adapter 8984-UPD and Engine Support Fixture 8534B. Lift the engine up a little so you have space to take out the oil pan and do not pry on the oil pan or its gasket because they can't be separated from the engine. M10 horizontal screws are 5 mm longer and must be put back into their previous positions. Take out the M10 fasteners connecting the rear of the oil pan to the transmission and then use the outlined order to remove the oil pan bolts and drop the oil pan. Because you cannot reuse the old gasket, the gasket/windage tray assembly needs to be replaced and the windage tray and gasket that come together should be disposed of.