JeepParts

My Garage

My Account

Cart

OEM Dodge Challenger Timing Belt

Engine Timing Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Timing Belt found

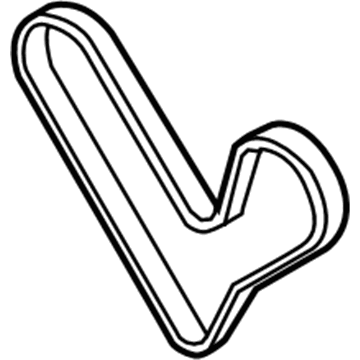

Dodge Challenger Timing Belt Part Number: 4792353

$90.37 MSRP: $127.00You Save: $36.63 (29%)

Dodge Challenger Timing Belt

Choose OEM Timing Belt that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Timing Belt follows strict manufacturing steps to lock in quality and fit. If your Dodge Challenger matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Challenger parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Timing Belt can be found in Dodge Challenger automobiles and it is responsible for maintaining a correct operation of the engine crankshaft and the camshaft, while controlling the intervals of the intake as well as the exhaust valves. This act of synchronization is very important since it puts the engine in a position whereby it is capable of giving account of every stroke of the engine. The timing belt is usually produced from rubber with fiber reinforcement and is built to offer tension resistance but has a relatively small life cycle that makes it vulnerable to failure which when happens means costly damage to the engine. Dodge Challenger models have more often than not incorporated timing belts in their models while others may include timing chains or gears, especially in older models of engines. New improvements have been made on the Timing Belts whereby they have been designed with curved teeth that enable them to last longer and are also a bit quieter. Sustaining this engine entails that general upkeep is practiced in addition to observing the appropriate time for replacements of different parts.

Dodge Challenger Timing Belt Parts and Q&A

- Q: How to Change the Timing Belt on a 3.5L Engine on Dodge Challenger?A:It's necessary to secure the 3.5L engine against independent rotation because this is not a freewheeling motor; make sure the valve train rocker assemblies are removed before attempting any Crankshaft or Camshaft rotation. Rotate the camshafts according to their timing marks and go no further than half a revolution so you do not harm the valves or pistons. Line up the crankshaft sprocket (10) with the TDC mark (9) on the oil pump cover and bring the camshaft sprocket (2) timing reference mark (1) into contact with the mark on the rear cover. Put the timing belt around the crankshaft sprocket (10) in the opposite of clockwise motion as you begin, stretching the belt as it is positioned above the tensioner pulley (11). Compress the companion plunger within the tensioner and add a locking pin before returning it to the installation site. While holding the pulley with one hand, attach the reset (pinned) Timing Belt Tensioner (2) to the housing with both hands using the 28 Nm (250 in. lbs.) torque wrench, then install them with the attaching bolts. As soon as the tensioner (12) is in position, take out the retaining pin to extend it toward the pulley bracket. Turn the crankshaft sprocket (10) two revolutions and look at the timing marks on both the camshafts and the crankshaft; if the marks do not match, start again. Set the front timing belt cover into place, join the negative Battery Cable and tighten the bolt to 5 Nm (45 in. lbs.) after installation. Fully fill the radiator with fluid, run the engine and monitor the fluid level inside the cooling system throughout. Whenever the Flywheel, valvetrain, camshaft or crankshaft sensors are replaced, the Cam/Crank Variation Relearn method is necessary.