JeepParts

My Garage

My Account

Cart

OEM Dodge Grand Caravan Steering Knuckle

Front Steering Knuckle- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Steering Knuckles found

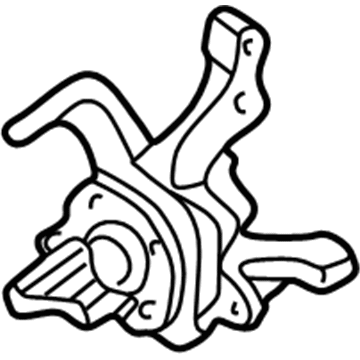

Dodge Grand Caravan Knuckle, Front Driver Side Part Number: 4694953AB

$402.36 MSRP: $614.00You Save: $211.64 (35%)Ships in 1-2 Business Days

Dodge Grand Caravan Knuckle, Front Part Number: 4694822

$360.81 MSRP: $457.39You Save: $96.58 (22%)Ships in 1-2 Business Days

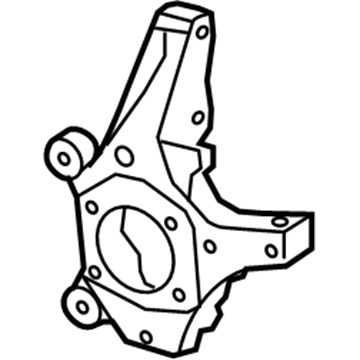

Dodge Grand Caravan Knuckle, Front Passenger Side Part Number: 4743568AE

$433.16 MSRP: $659.00You Save: $225.84 (35%)Ships in 1-2 Business Days

Dodge Grand Caravan Knuckle, Front Driver Side Part Number: 4743569AE

$38.45 MSRP: $55.75You Save: $17.30 (32%)

Dodge Grand Caravan Knuckle, Front Part Number: 5015935AA

Dodge Grand Caravan Knuckle, Front Part Number: 5015934AA

Dodge Grand Caravan Knuckle, Front Part Number: 4694823

Dodge Grand Caravan Knuckle Part Number: 4449458

Dodge Grand Caravan Steering Knuckle

Choose OEM Steering Knuckle that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Steering Knuckle follows strict manufacturing steps to lock in quality and fit. If your Dodge Grand Caravan matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Grand Caravan parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

The Steering Knuckle of the Dodge Grand Caravan plays an important role in the vehicles ways it is suspended and steered uniting the front wheels with the upper and lower control arms or struts. Through this design it is possible to have the vertical motion depending on the road surface together with the horizontal motion depending on the direction where the steering is pulled or pushed as this makes the wheel to rotate as required. Concerning the Steering Knuckles used on Dodge Grand Caravan through the years, these are primarily by the drive types, front-wheel drive (FWD), all-wheel drive (AWD) and four-wheel drive (4WD) types. Both types have different structures, for example, FWD/AWD/4WD has hubs which are bolted to the Steering Knuckle while RWD cars could have an integral spindle that is located in the Steering Knuckle. It is recommendable for the Steering Knuckle to be inspected and tested often, especially when changing the suspension parts, so that the Dodge Grand Caravan can be optimized and safe to use again.

Dodge Grand Caravan Steering Knuckle Parts and Q&A

- Q: How to Remove the Front Steering Knuckle on Dodge Grand Caravan?A:Lift and support your car and then remove the nuts holding the wheel and tire to the suspension before getting out the front steering knuckle. Assisting with the brakes, slowly take away the hub nut attached to the axle halfshaft stub shaft. Firmly press the end of the stub shaft inward on the halfshaft to separate their splines. After accessing the front brake rotor and taking it out, unscrew the brake shield at the knuckle and remove the brake shield. Take out the wheel speed sensor connector from the wiring harness and disconnect the connector from its mounting on the frame rail. Unscrew the screw that attaches the wheel speed sensor routing bracket to the strut mounting flange and then unfasten the second screw of that bracket on the knuckle. First, use the Puller, Special Tool 9360, to remove the outer tie rod stud after you detach the nut that connects the tie rod to the steering knuckle and hold the outer tie rod stud still. When dealing with either the left or right knuckle, make sure the bolt heads do not move, remove the two nuts from the bolts and then pop out the two bolts using a pin punch. Tip the knuckle upwards and use a wire to hang the halfshaft stub shaft straight down from the hub and bearing. The tapered stud must still be held in the knuckle, so secure it using an impact wrench to remove the ball joint nut. Reinstall the nut so it is at the same level as the ball joint stud, to prevent changing the shape of the ball joint when you move on. Fit Press, Special Tool C-4150A, over the stud and nut, then tighten the screw-drive to remove the stud from the steering knuckle. With the tool and nut out of the way, pull the steering knuckle from the car. If you must switch the hub and bearing to another knuckle, remove all four bolts and lift out the hub and bearing.

- Q: How to install a Steering Knuckle on Dodge Grand Caravan?A:If the hub and bearing are going in, mark their position so that the threaded mounting holes in the hub are opposite the holes in the steering knuckle. Place and tighten the four bolts by hand, then add torque to a level of 65 Nm (45 ft. lbs.). Before attaching the knuckle to the stud, wipe the contact area on each with a clean cloth and cleaner to keep both clean and damage-free. Then, push the knuckle on the ball joint stud and put on a NEW steering knuckle to ball joint stud nut, tightening it to a torque of 108 Nm (80 ft. lbs.) as you hold the ball joint stud in place with a hex wrench. Guide the back part of the driveshaft stub axle into the wheel hub until the bearing applies pressure to the front side of the driveshaft stub axle. If the vehicle comes with eccentric bolts, put one of those bolts into the lower (slotted) hole in the clevis bracket of the strut. You should install the bolts between the strut clevis and steering knuckle from the rear to front on the left and from front to rear on the right side. Position the steering knuckle in the clevis bracket of the strut damper, add the clevis-to-steering knuckle bolts and torque them to 81 Nm (60 ft lbs.) after a further 1/4 (90°) turn. After that, put the Tie Rod End inside the steering knuckle and start screwing on the nut until it reaches 75 Nm (55 ft. lbs.) while you hold the stud still. When the vehicle has antilock brakes, join the wheel speed sensor to the steering knuckle and screw in the mounting bolt to 7 Nm (60 in lbs. of torque). Mount the brake rotor to the hub and bearing, then the disc Brake Caliper and assembly to the steering knuckle, using the bolts to tighten the adapter until you have 169 Nm (125 ft. lbs.) of force. Carefully clear away any particle from the outer C/V joint stub axle and afterwards attach the washer and hub nut to the stub axle. As your helper stops the hub from turning with the vehicle's brakes, tighten the hub nut to 244 Nm (180 ft. lbs.). Place the spring wave washer on the stub axle's end, insert the hub nut lock and thread a new cotter pin to wrap tightly around the lock nut. Then, fix the wheel and tire assembly, using a half-handed turn per nut and start repeating the full sequence until you reach the required tightness of 135 Nm (100 ft.lbs.), finish lowering your vehicle and make any necessary front wheel alignment to set the now-installed tires.