JeepParts

My Garage

My Account

Cart

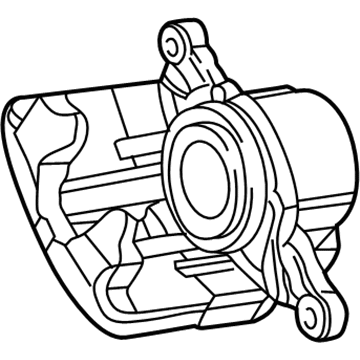

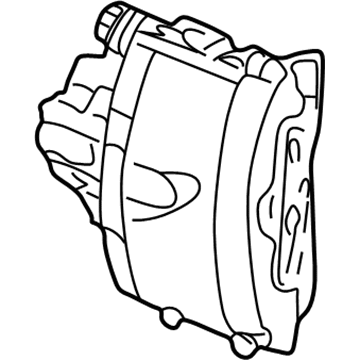

OEM Dodge Stratus Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Brake Calipers found

Dodge Stratus Caliper, Rear Passenger Side Part Number: 5019743AB

$89.99 MSRP: $159.00You Save: $69.01 (44%)Ships in 1-2 Business DaysDodge Stratus Caliper, Front Passenger Side Part Number: MR527671

$49.02 MSRP: $62.15You Save: $13.13 (22%)Ships in 1-2 Business DaysDodge Stratus Caliper, Rear Driver Side Part Number: 5019744AB

Dodge Stratus Caliper Assembly Part Number: 4856923

Dodge Stratus Caliper Assembly Part Number: 4856922

Dodge Stratus Caliper, Front Passenger Side Part Number: MR449856

Dodge Stratus Caliper, Front Driver Side Part Number: MR449855

Dodge Stratus Caliper, Rear Passenger Side Part Number: MR129584

Dodge Stratus Caliper Assembly, Rear Driver Side Part Number: MR129583

Dodge Stratus Caliper, Front Driver Side Part Number: 5072551AA

Dodge Stratus Caliper, Front Passenger Side Part Number: 5018990AA

Dodge Stratus Caliper Assembly Part Number: 5011701AA

Dodge Stratus Caliper Assembly Part Number: 5011700AA

Dodge Stratus Caliper, Front Passenger Side Part Number: 4605A019

Dodge Stratus Caliper, Front Passenger Side Part Number: 4605A018

Dodge Stratus Brake Caliper

Choose OEM Brake Caliper that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Brake Caliper follows strict manufacturing steps to lock in quality and fit. If your Dodge Stratus matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Stratus parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

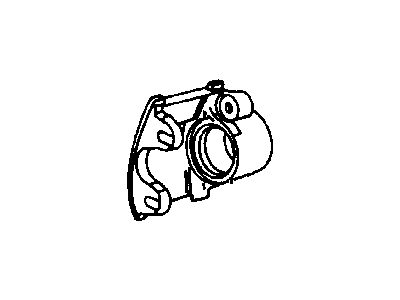

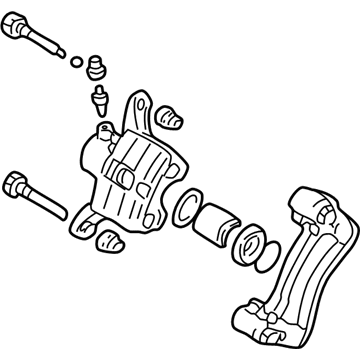

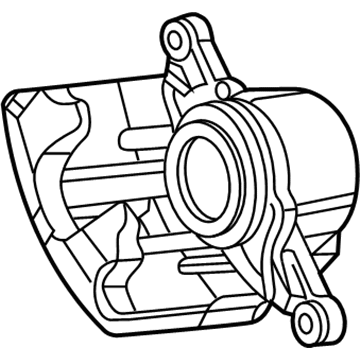

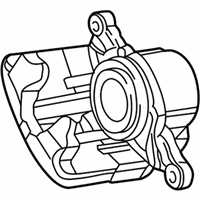

It is an auto part called the Brake Caliper critical for the braking process and famous for effectiveness in most Dodge Stratus sedans/champagne models made between 1995 and 2005. This Brake Caliper equally has a very crucial role of increasing efficiency and safety by accurately clamping the brake pads against the rotors as required to produce the friction necessary to stop the vehicle. Fixed and floating Brake Caliper are fix available, the fixed brake caliper ensure premier clamping force while the floating brake caliper are comparatively more flexible. The Brake Caliper is responsive to various engines like 2.0-Liter Inline-four, and 2.7-Liter Inline-Six therefore regarded highly by drivers who want a car with perfect braking system. For instance, the Brake Caliper was developed with the functionality of preventing or reducing on sticking that could reach out to Pad wear and decline in fuel efficiency. This shows the importance of the Brake Caliper towards the general performance of the car as much details is being paid towards it. Furthermore, the Brake Caliper has some advantages on the car market because of its durability and reliability that shows that owners of the Dodge Stratus car will be safe both for themselves and for others on the roads. The Brake Caliper is still an influential design element of the Stratus model due to its combination of innovation and stability of the brake caliper for vehicles' owners who value quality in their vehicle.

Dodge Stratus Brake Caliper Parts and Q&A

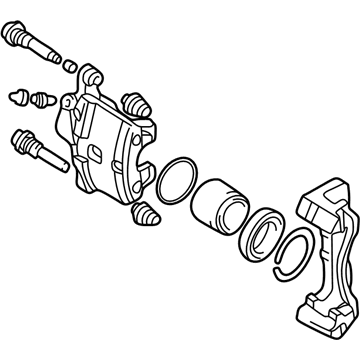

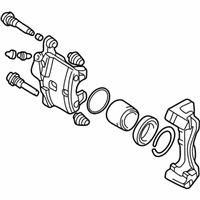

- Q: How to Maintain a Rear Brake Caliper on Dodge Stratus?A:To begin the service process for a rear disc brake caliper, push down on the brake pedal until it feels like you've pressed it 1 inch, then use a brake pedal depressor so no brake fluid leaks from the reservoir. Get the vehicle up on jacks and pull out the rear wheel and tire. Disconnect the hose from the caliper by removing the banjo bolt and discarding the pair of washers that slide off with it. Take out the two guide pin bolts holding the caliper to the adapter, then rotate the caliper and pull it off the lower machined abutment. Cleansing and inspecting the caliper should be the first step before you begin unscrewing it. Twist the bushing on the guide pin toward the back of the case and slip it out with the help of your fingertips and perform this action also on the opposite bushing. Hang the caliper off a wire hook away from the rotor and body, insert a piece of wood between the fingers of the caliper and Piston and gently push the brake pedal to pull the piston out. Hold the brake pedal down so that fluid doesn't drain out. After that, disconnect the brake fluid flex hose. Place the caliper between the jaws of a vise, remove and throw out the piston dust boot and then carefully extract the old piston seal from the cylinder bore with a soft tool. Carefully inspect and clean the piston bore and if you see minor scratches, use crocus cloth on it. When you clean the brake parts, spray them with water using a timely cloth, gather up any waste and store it in a secured container labeled as hazardous. Brush liberal strokes of Mopers Dielectric Grease inside the bushing and slide it into the caliper boss so that its half unfolded. Introduce clean brake fluid into a new piston seal and slide it into place in the groove, then coat a new piston boot with brake fluid and set it over the piston. Subject the piston to even pressure so that it fits in the cylinder bore, then use Tool C-4689 or C-4842 and Handle C-4171 as needed to put on the dust boot in the counterbore. Put the caliper back on the car, with its piston fully retracted, add grease to the adapter holes and if taken out, install the rotor directly onto the hub's center. Lower the brake shoes and caliper on top of the rotor, but don't damage the guide pin bushings or sleeves. Place the caliper guide pin bolts and tighten them to 22 Nm (192 inch lbs.). Afterward, place the brake hose with new washers and fasten them with a tightened banjo bolt which should be tightened to 35 Nm (26 ft.lbs.). After reinstalling the wheel and tire, tighten the stud nuts just halfway, then torque to 135 Nm (100 ft. lbs.) when done. Prop up the vehicle, free the brake pedal depressor, bleed the hydraulic brake line and test the brakes on the road.

- Q: How to Service and Repair a Front Brake Caliper on Dodge Stratus?A:To deal with front disc brake caliper service or repair, push the brake pedal much further than its first inch and clamp it down with a brake pedal depressor to separate the master cylinder from the fluid. Wheel and tire assemblies can only be replaced once you raise the vehicle and remove the front wheel and tire. Disconnect the anti-rattle spring on the outboard side of the caliper and adapter, then cut loose the banjo bolt that ties the brake hose to the caliper, discarding the two washers. Then, take off the caps over the caliper guide pin bolts and then get rid of the bolts. Remove the caliper from the adapter and brake rotor and remember that while the exterior shoe (outboard) stays on the adapter, the interior shoe (inboard) comes off with the caliper. To install, pull the caliper piston all the way into the bore and put Mopers Dielectric Grease or a compatible substance on the caliper adapter abutments. If new brake linings are being placed or are crossing sides, the inboard side of the shoes must be marked L or R for left or right. Insert the brake caliper between the brake rotor, outboard shoe and adapter, then install the guide pin bolts at 35 Nm (26 ft. lbs.), being careful not to twist them. Apply the caps above the guide pin bolts and fix the anti-rattle spring to the caliper on the outside opposite the hub. Before screwing in the brake hose, secure two special washers on each side of the fitting, put the banjo bolt with a patent bolt through and turn it clockwise on the caliper until it has been tightened to 35 Nm (26 ft. lbs.). Reattach the wheel and tire as a group, fastening the stud nuts step by step and to a tightness of half specification, then up to 135 Nm (100 ft. lbs.). Raise the car up, return the brake pedal depressor, fill the braking system and test how the vehicle drives after applying the brakes.