JeepParts

My Garage

My Account

Cart

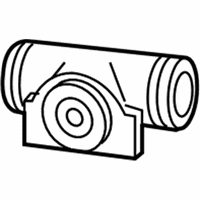

OEM Dodge Stratus Wheel Cylinder

Brake Wheel Cylinder- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Wheel Cylinders found

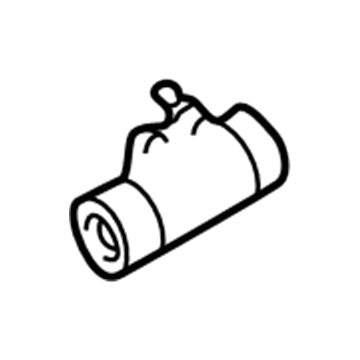

Dodge Stratus Wheel Cylinder, Rear Part Number: 5096244AA

$38.66 MSRP: $49.01You Save: $10.35 (22%)Ships in 1-2 Business DaysDodge Stratus Wheel Cylinder Part Number: 4728859

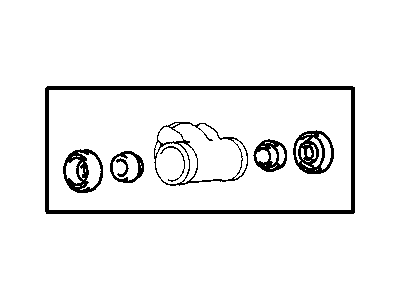

$8.48 MSRP: $10.75You Save: $2.27 (22%)Ships in 1-2 Business DaysDodge Stratus Wheel Cylinder Overhaul Kit Part Number: MB134975

$7.10 MSRP: $11.54You Save: $4.44 (39%)Ships in 1-2 Business DaysDodge Stratus Wheel Cylinder, Rear Part Number: MB193411

Dodge Stratus Wheel Cylinder

Choose OEM Wheel Cylinder that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Wheel Cylinder follows strict manufacturing steps to lock in quality and fit. If your Dodge Stratus matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Stratus parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

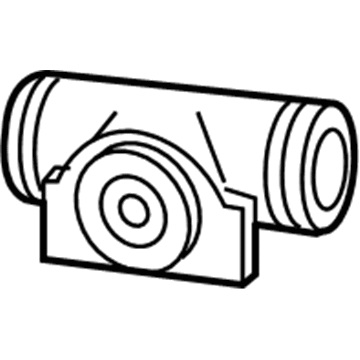

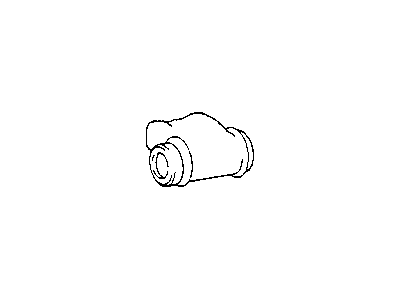

The Dodge Stratus Wheel Cylinder is a very important component that greatly increases the available reliability and performance of the Dodge Stratus line of vehicles manufactured between 1995 and 2005. This hydraulic system is central in ensuring that pressure is applied to the brake shoes to get them in tactile contact with the brake drum so as to safely slow down or Stop the vehicle. Made mainly of aluminum in order not to rust or corrode, the Dodge Stratus Wheel Cylinder comes in sophisticated designs namely, dual single piston type in order to enhance the braking system of the car. The availability of clips for both, the Dodge Stratus sedan and coupe versions shows its versatility and necessity for ensuring the car's safety. Excessive usage of the wheel cylinder results in leakage; nevertheless, due to its simplicity, drivers can easily replace or reestablish their braking mechanism. Dodge Stratus Wheel Cylinder not only improves the braking system but also plays its role in the safety of driving standards hence is a must-have part for every Stratus car user. The Dodge Stratus Wheel Cylinder gains its popularity from the markets due to its endurance and reliability that it gives assurance to people who are cautious concerning their automobiles. From the city driveway to an out of town drive on the highway the Dodge Stratus Wheel Cylinder can not be underestimated while it is still a reliable car for the cost conscious buyer.

Dodge Stratus Wheel Cylinder Parts and Q&A

- Q: How to Disassemble and Reassemble Wheel Cylinders on Dodge Stratus?A:To remove the wheel cylinders, work the boot away from the cylinder and remove it. Press the IN button on one Piston to make the other piston, cup and spring pop back. Use a soft tool such as a dowel rod to plunge out the last bit of cup and piston from the wheel cylinder. Clean the pistons, wheel cylinder and spring with brake fluid or alcohol instead of petroleum, blow dry after a complete clean and test them using the proportion of brake fluid. Look for scratches and small dents in the cylinder and on the piston and avoid using a rag since its lint could attach to the cylinder bore. Wheel cylinder bores and pistons with severe wear need to be replaced, but wheeling lightly scratched or corroded cylinder walls with a crocus cloth works pretty well. Marks from the piston cups on the cylinder surface will not affect cylinder use. Before putting the pistons and new cups in the wheel cylinders, clean them by dipping them in fresh brake fluid. Should the boots be damaged, cracking or too loose around the pistons, replace them with new ones. Rub the inside of the cylinder bore with brake fluid and spray a very thin coat of Mopar Protect-A-Cup Lubricant on the outside and sealing lip of each wheel cylinder cup. Mount the expansion spring along with the cup expanders inside the cylinder and then slide the cups into each end of the cylinder, opening facing opening. Lastly, insert a piston into each end of the cylinder, so their flat faces touch the flat sides of the cups and make sure not to damage the boots either.

- Q: How to Effectively Service and Repair a Wheel Cylinder on Dodge Stratus?A:Before attempting any service or repair on the wheel cylinder, don't forget to release the parking brake. Press the brake pedal off the floor about one inch and then use a brake pedal depressor tool to hold it in this spot, trapping the master cylinder from the brake hydraulic system and keeping the brake fluid from flowing away during disconnection. First, raise the vehicle, then take the tire and wheel off, next remove the flex hose tube nut from the wheel cylinder and take out the hose, making sure to cap it. Then, take out the Brake Drum and the wheel cylinder mounting bolts and ease the cylinder and seal gently from their place between the brakes and the back plate. Install the seal on the wheel cylinder's mounting surface, add the cylinder between the brake shoes on the support plate and tighten the mounting bolts to 13 Nm (115 in. lbs.). Check the brake shoe gauge to fit them to the brake drum diameter and then install the drum onto the axle. Place the flex hose tube nut into the wheel cylinder port and tighten it to 145 in. lbs. (17 Nm) measured with a torque wrench. Place and tighten the wheel and tire assembly in position, with all wheel mounting nuts at 135 Nm (100 ft. lbs.) torque. Spin the wheel by hand after placing the brake shoes on the drum, drop the vehicle and take out the brake pedal depressor rod. Drain the affected wheel cylinder or circuit if necessary. Run a test drive, checking that the car brakes normally in both forwards and reverse gears, while the automatic-adjuster is keeping the brakes properly adjusted throughout the test.