JeepParts

My Garage

My Account

Cart

OEM Jeep Liberty Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Universal Joints found

Jeep Liberty Universal Joints Part Number: 5015694AB

$81.00 MSRP: $124.00You Save: $43.00 (35%)Ships in 1-2 Business Days

Jeep Liberty Universal Joints Part Number: 5014733AB

$59.52 MSRP: $130.00You Save: $70.48 (55%)Ships in 1-3 Business Days

Jeep Liberty Universal Joint

Choose OEM Universal Joint that meet Jeep factory standards. Jeep designs and tests every component for precision and durability. Each Universal Joint follows strict manufacturing steps to lock in quality and fit. If your Jeep Liberty matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Liberty parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

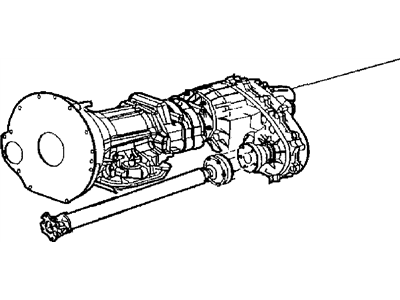

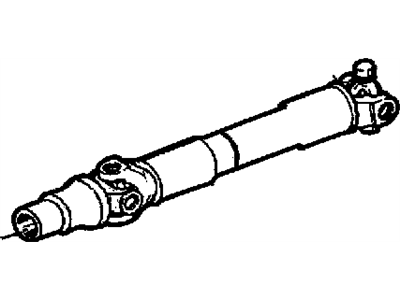

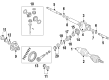

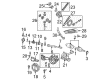

Universal Joint of Jeep Liberty is used to link the driveshaft to the differential to provide required mobility when the suspension of the vehicle interacts with the surface it is operating on. This component also allows the driveshaft to turn and therefore flex to be able to accommodate for changes in angles between the transmission and differential. Originally, the Jeep Liberty Universal Joint comprises of a cross which is fitted with needle bearings enveloped in hardened steel cups that are clamped in place by clips. Jeep Liberty models that have been produced throughout the years have had factory pre-lubricated Universal Joints at some time or another and some parts have grease zerks for replenishment. The first difference concerns the fact that Universal Joints may be greasable meaning that they can be refilled with more grease to increase their durability. It is recommended that the Universal Joint should always be checked often since when the joints wear out, there are signs such as noises and vibrations which may be an indication that it is time for a change of the Universal Joint for better vehicle performance.

Jeep Liberty Universal Joint Parts and Q&A

- Q: How to Maintain Universal Joints for Optimal Performance on Jeep Liberty?A:For this type of universal joint, each piece can't be opened or serviced; if they're damaged or leaking, the entire joint should be replaced at once. Start the job by detaching the propeller shaft. To loosen the snap ring, strike the outside of the bearing cap assembly with a drift, then remove the snap rings that are holding the yoke. Place the bearing cap in a yoke that fits an arbor press or a vise. While placing it, face the grease fitting upward if it is present. Press the upper bearing cap with a socket that is smaller outside than the cap, so that it passes through the yoke and releases the lower bearing cap. Should the bearing cap not pull out by hand after pressing, strike the yoke ear closely above it to remove it. By turning the yoke over and inserting the square bar in the hole, the top of the cross presses on the bearing cap and you can then remove it. Keep the cross or bearing cap aligned during installation to avoid putting scratches on the inside of the yoke bore. Put EP N.L.G.I. Grade 1 or 2 mode grease inside the yoke bore opening for assembly. Set the cross into the yoke so that the top end of the lube fitting, if you have one, is pointing up. Cover the trunnion with its bearing cap, putting it exactly over the yoke bore and keeping the needles pointing up. Tuck the bearing cap into the yoke where it is clear of the snap ring and set in a snap ring afterward. Follow the steps to install the bearing cap on the other side. Strike the yoke gently with a soft hammer when the joint is found to be stiff or binding, in order to set the needle bearings. Put some grease on the lube fitting, if your boat has one and fit the propeller shaft again.

- Q: How to Maintain and Repair a Universal Joint with Snap Rings on Jeep Liberty?A:To work on a universal joint with snap rings, first put some EP N.L.G.I. Grade 1 or 2 grease on the inside of the yoke bores. If you have a lube fitting, connect the yoke to the (1) cross with it pointing up (2). Put the bearing cap (1) over the cross end (2), align it with the yoke bore and push it into the yoke bore until it rises above the snap ring groove. Go through the procedure to handle the second bearing cap as well. If you find the joint feels tight or difficult to move, cure it by tapping the yoke with a soft hammer to ensure the needle bearings are seated. If you have a grease-equipped lube fitting, grease it last.