JeepParts

My Garage

My Account

Cart

OEM Jeep Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

90 Oxygen Sensors found

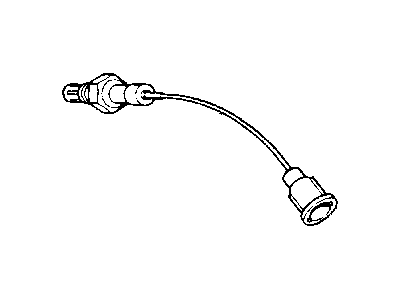

Jeep Oxygen Sensor, Front Driver Side Part Number: 56028997AA

$97.14 MSRP: $148.00You Save: $50.86 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor - Oxygen; Oxygen Sensor, Front Left, Rear, Rear Left; Rear Oxygen Sensor; Front Oxygen Sensor; Sensor Oxygen

- Position: Front Driver Side

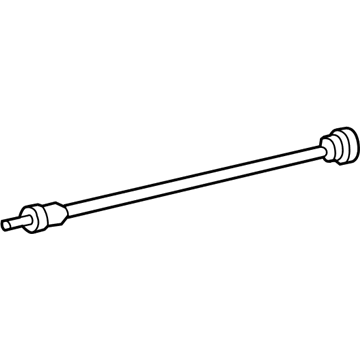

Jeep Front Oxygen Sensor, Passenger Side Part Number: 56044581AA

$69.20 MSRP: $147.00You Save: $77.80 (53%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor - Oxygen; Oxygen Sensor, Front Right; Sensor Oxygen; Oxygen Sensor

- Position: Front Passenger Side

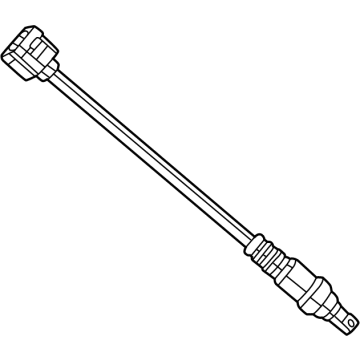

Jeep Oxygen Sensor, Rear Driver Side Part Number: 56041345AE

$209.09 MSRP: $265.05You Save: $55.96 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor - Oxygen; Oxygen Sensor, Rear Left; Rear Oxygen Sensor; Sensor Oxygen

- Position: Rear Driver Side

Jeep Oxygen Sensor, Rear Part Number: 5139021AA

$119.04 MSRP: $179.00You Save: $59.96 (34%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor Packkage - Oxygen; Oxygen Sensor, Rear; Rear Oxygen Sensor; Sensor Package Oxygen

- Position: Rear

- Replaces: 56044598AA

Jeep Oxygen Sensor, Front Part Number: 5149171AB

$129.16 MSRP: $190.00You Save: $60.84 (33%)Product Specifications- Other Name: Sensor - Oxygen; Oxygen Sensor, Front, Front Left, Front Right, Rear, Rear Left, Rear Right; Oxygen Sensors: Front, Rear, Upper, Lower, Passenger/Driver Side, Before/After Catalytic Converter.

- Position: Front

- Replaces: 5149171AA, 68066160AA

Jeep Oxygen Sensor, Front Driver Side Part Number: 56029049AA

$97.32 MSRP: $144.00You Save: $46.68 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor - Oxygen; Oxygen Sensor, Front, Front Left, Front Right, Rear, Rear Left, Rear Right; Rear Oxygen Sensor; Front Oxygen Sensor; Upper Oxygen Sensor; Lower Oxygen Sensor; Sensor Oxygen

- Position: Front Driver Side

Jeep Oxygen Sensor, Front Part Number: 68224424AA

$69.52 MSRP: $104.00You Save: $34.48 (34%)Product Specifications- Other Name: Sensor - Oxygen; Oxygen Sensor, Front, Front Left, Front Right, Rear, Rear Left, Rear Right; Rear Oxygen Sensor; Downstream and upstream sensors for catalytic applications.

- Position: Front

Jeep Oxygen Sensor, Front Part Number: 56029050AA

$77.38 MSRP: $114.00You Save: $36.62 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor - Oxygen; Oxygen Sensor, Front, Front Right, Rear, Rear Left, Rear Right; Rear Oxygen Sensor; Front Oxygen Sensor; Lower Oxygen Sensor; Sensor Oxygen

- Position: Front

Jeep Oxygen Sensor, Rear Passenger Side Part Number: 56041731AA

$173.40 MSRP: $231.00You Save: $57.60 (25%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor - Oxygen; Oxygen Sensor, Rear Right; Rear Oxygen Sensor; Sensor Oxygen

- Position: Rear Passenger Side

Jeep Nitrogen Oxide Sensor Part Number: 68544292AA

$751.40 MSRP: $1150.00You Save: $398.60 (35%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bracket - Downstream Nitrogen Oxide/Pm

- Replaces: 68297516AB, 68297516AC

Jeep Nitrogen Oxide Sensor Part Number: 68544289AA

$348.08 MSRP: $510.00You Save: $161.92 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Sensor - Nitrous Oxide

- Replaces: 68297527AA

Jeep Oxygen Sensor Part Number: 56027902

Product Specifications- Other Name: Sensor - Oxygen-22" Pigtail

Jeep Oxygen Sensor Part Number: 56041219

Product Specifications- Other Name: Sensor - Oxygen; Sensor Oxygen

Jeep Oxygen Sensor Part Number: 56041111

Product Specifications- Other Name: Sensor - Oxygen; Sensor Oxygen

Jeep Oxygen Sensor, Front Passenger Side Part Number: 56041941AA

Product Specifications- Other Name: Sensor - Oxygen; Oxygen Sensor, Front Right; Front Oxygen Sensor; Sensor Oxygen

- Position: Front Passenger Side

Jeep Oxygen Sensor, Rear Part Number: 56028235AA

Product Specifications- Other Name: Sensor - Oxygen; Oxygen Sensor, Rear; Rear Oxygen Sensor; Sensor Oxygen

- Position: Rear

Jeep Oxygen Sensor Part Number: 56044215AA

Product Specifications- Other Name: Sensor - Oxygen; Rear Oxygen Sensor; Sensor Oxygen

Jeep Oxygen Sensor, Front Part Number: 56041943AA

$192.61 MSRP: $284.00You Save: $91.39 (33%)Product Specifications- Other Name: Sensor - Oxygen; Oxygen Sensor, Front; Front Oxygen Sensor; Sensor Oxygen

- Position: Front

Jeep Oxygen Sensor, Front Passenger Side Part Number: 68466620AA

$81.18 MSRP: $123.00You Save: $41.82 (34%)Product Specifications- Other Name: Sensor - Oxygen; Oxygen Sensor, Front Right; Front Oxygen Sensor

- Position: Front Passenger Side

Jeep Oxygen Sensor, Rear Part Number: 56041344AD

Product Specifications- Other Name: Sensor - Oxygen; Oxygen Sensor, Rear; Rear Oxygen Sensor; Sensor Oxygen

- Position: Rear

| Page 1 of 5 |Next >

1-20 of 90 Results

Jeep Oxygen Sensor

OEM parts sourced directly from Jeep deliver superior quality, long lasting strength, and a precise fit you can trust. Each item goes through strict quality checks to ensure safety, toughness, and performance that matches your factory equipment. At JeepPartsDeal online shop, you'll get top-quality, budget-friendly OEM Jeep Oxygen Sensor for your vehicle. We focus on giving you a high standard without pushing up the price. Our full selection of genuine factory products comes backed by the original manufacturer's warranty. You'll love our fast delivery, seamless shopping experience, and convenient return policy, saving you all the hassle.

Jeep Oxygen Sensor ensures breathing is correct in the engine, cutting waste gases and saving a mile of fuel. Jeep is successful on both the rugged roads and urban streets. It began way back in 1945 and its origins were to work hard and walk free. Out of that came a cult of the open-air rides, removable doors, and flat fenders that shake off dents. Selec-Terrain dial enables drivers to turn to snow, sand, or mud without slowing down. Current cabins are combined with rugged grab handles and sharp screens, voice control, and rapid over-the-air adjustments. Community is strong, and the owners exchange trail tips and wave over highways like long-lost friends. Jeep loyalty is here to stay since the rigs are providing the actual application rather than showroom vapor. Top off, tires deflated, these machines can climb the rocks and cross streams without a melodramatic appearance. The Oxygen Sensor within the exhaust path compares the exhaust gas to the outside air in real time, transmitting a voltage signal to the control unit and triggering microscopic fuel adjustments that reduce emissions, eliminate power loss, and ensure your wallet is not emptied at the pump. A hot Oxygen Sensor warms up in a few seconds, causing cold starts to remain clean. This benefit is obtained by many Jeep owners without having to touch a wrench. When the Oxygen Sensor becomes old and deteriorates, the mixture is rich, the mileage decreases, and the tailpipe smoke increases. Replacement of a new Oxygen Sensor and Jeep engines immediately recovers the lost clarity of their feedback loop.

Jeep Oxygen Sensor Parts and Q&A

- Q: How to Properly Service an Oxygen Sensor on Jeep Grand Cherokee?A:Ensure the oxygen sensor is serviced with caution, don't apply grease to the electrical connector and don't solder the wires of the oxygen sensor harness because this sensor needs a supply of outside oxygen through its pigtail wiring harness. Before you begin, let the exhaust manifold, exhaust pipes and catalytic converter(s) cool, because they get very hot while the engine runs. Bring the vehicle up, then separate the O2S pigtail harness from the main wiring harness and, if there are, disconnect the sensor wire harness clips mounted on the engine or body, making sure not to hold the wire tightly as you do this. You need a special O2S sensor removal and installation tool to do the job. New oxygen sensors are applied with anti-seize substance straight from the factory, so no more should be put on. After installing the O2S sensor, tighten it to 30 Nm (22 ft. lbs.); then, attach the O2S sensor wire connector to the main wiring harness. Once you have the tool, reattach the sensor wire clips to the engine or body, attach the O2S pigtail harness to its original places so it cannot be damaged and after everything is in place, lower the vehicle.

- Q: How to Maintain the Oxygen Sensor on a 2.4L Engine on Jeep Wrangler?A:Be sure to wait until the engine has cooled before servicing the oxygen sensor, because these parts of the exhaust system become extremely hot while you drive. First, lift and secure the vehicle, then isolate the wire connector from the O2S sensor, always making sure not to tug straight on the cable leading to it. You should use the special tool for removing the sensor to take out the O2S and follow that with cleaning the exhaust threads by using an appropriate sized tap. Remember that the new O2S is factory coated with anti-seize compound, so do not add any further coating. Place the O2S sensor, secure it at 30 N.m (22 ft.lbs.) tightness and reconnect its wire and then drop the vehicle to the ground.