JeepParts

My Garage

My Account

Cart

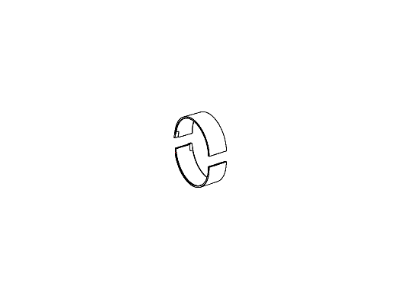

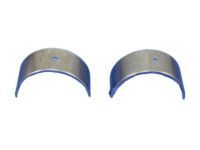

OEM Jeep Wrangler Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Rod Bearings found

Jeep Wrangler Connecting Rod Bearing Part Number: 5184111AF

$3.76 MSRP: $5.65You Save: $1.89 (34%)Ships in 1-2 Business Days

Jeep Wrangler Connecting Rod Bearing Part Number: 5184113AF

$3.83 MSRP: $5.65You Save: $1.82 (33%)Ships in 1-2 Business Days

Jeep Wrangler Bearings Part Number: 5174612AA

$14.57 MSRP: $24.10You Save: $9.53 (40%)

Jeep Wrangler Bearings Part Number: 5161294AA

$18.30 MSRP: $27.05You Save: $8.75 (33%)Ships in 1-2 Business Days

Jeep Wrangler Connecting Rod Bearing Part Number: 68362046AA

$16.59 MSRP: $24.55You Save: $7.96 (33%)Ships in 1-2 Business Days

Jeep Wrangler Connecting Rod Bearing Part Number: 4893952AA

$10.56 MSRP: $15.40You Save: $4.84 (32%)Ships in 1-3 Business DaysJeep Wrangler Rod Bearings Part Number: 83500300AC

$17.36 MSRP: $22.95You Save: $5.59 (25%)Ships in 1-2 Business Days

Jeep Wrangler Connecting Rod Bearing Part Number: 5184112AF

$16.30 MSRP: $23.55You Save: $7.25 (31%)Jeep Wrangler Connecting Rod Bearing, Red Part Number: 4893537AB

$7.89 MSRP: $11.55You Save: $3.66 (32%)

Jeep Wrangler Rod Bearing

Choose OEM Rod Bearing that meet Jeep factory standards. Jeep designs and tests every component for precision and durability. Each Rod Bearing follows strict manufacturing steps to lock in quality and fit. If your Jeep Wrangler matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Wrangler parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

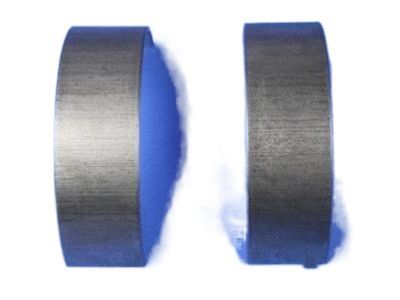

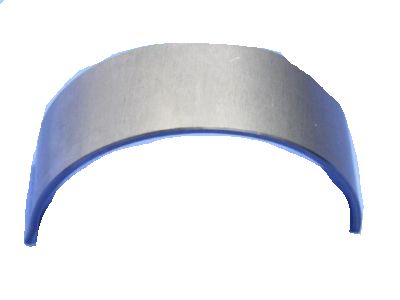

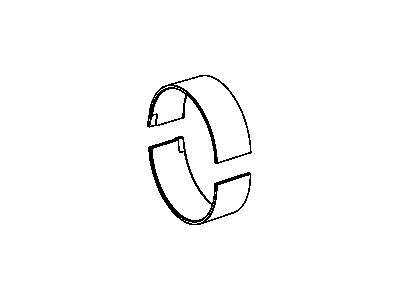

Rod Bearing is one of the critical parts, which play the major role in improving the quality and functionality of Jeep Wrangler automobiles. Located between the crankshaft and connecting rods to hold the latter and facilitate rotation because friction is not desirable in an engine, can be described as a Rod Bearing. Rod Bearings have been used on Jeep Wranglers for as long as there has been the Jeep Wranglers, and tri-metal was considered to be more durable and strong for models that gave more power. Applications of these Rod Bearings are specially designed to endure off-road conditions and thus, well recommended for Jeep users. The fourteen hundred application Rod Bearing is suitable for various models of Jeep Wrangler and can fit both the basic two-door and the four-door Jeep Wrangler Unlimited. It has a significant function in increasing safety because the installation and maintenance of these Rod Bearings are vital to avoid the failure of the engine and to increase the life of the engine. Additional options included in the Rod Bearing include proprietary coatings and contained eccentricity making the automotive product to stand out in the market through facilitating oil clearance and minimizing friction for high resistance engines. Pros of Rod Bearing: Since the Jeep Wrangler is known for being a very dependable and functional car, Rod Bearing is an important feature which adds to the functionality of the Wrangler, making it an important addition for any Jeep Wrangler owner, thus improving the car's performance on the road and off the road alike.

Jeep Wrangler Rod Bearing Parts and Q&A

- Q: What is the Role of Rod Bearing in Measuring Engine Crankshaft Bearing Clearances with Plastigage on Jeep Wrangler?A:The best way to measure engine Crankshaft bearing clearances is to use Plastigage or a similar technique. Start by removing any existing oil coating, because Plastigage will dissolve in oil. After that, put a bit of Plastigage across the entire width of the bearing shell in the cap, centered about 6.35 mm (1/4 inch) from the oil holes and away from any suspected areas; areas outside these can also be checked using Plastigage. Secure the bearing caps to the axle while stating at the width of the flattened Plastigage on the package to find the equivalent band from the metric scale and read the clearance in thousandths of a millimeter. Differences in the readings between the two ends suggest how much the shaft tapers, so remember to write down every measurement. Make sure clearance measurements fit the engine specifications; remember, different Plastigage ranges are available for different situations. After you have cleaned the engine, attach the right crankshaft bearings for the right bearing clearances.

- Q: How to Inspect and Replace Rod Bearings for Optimal Alignment and Clearance on Jeep Wrangler?A:Examine the rod bearings for evidence of scoring, damage in the tabs and any irregular signs of wear, scoring, grooving, fatigue or pitting. Erase any bearing with signs of abnormal wear. Be sure to search the journals of the connecting rods for signs of scoring, nicks and burrs, as bent or misaligned connecting rods may cause extra wear to the Pistons, piston rings, cylinder walls, connecting rod bearings and Crankshaft connecting rod journals. Damage or unusual wear may show a misaligned connecting rod, so check it for alignment and change any misshapen or bent rods. First wipe off any oil from the junior and when assembling the rod, cover the bolt with short pieces of rubber hose. Place some oil on the upper bearing insert, then put it in place within the connecting rod. Lift the Camshaft high enough to fit the rod and piston under the valve, place the assembly above the compressor and then compress it so the oil squirt holes on the rod are facing the camshaft and the arrow on the piston points up front. Set the dry lower bearing insert into the bearing cap and put a piece of Plastigage at the center of the bottom insert on the cap so it doesn't crumble. Put the bearing cap and connecting rod in place and tighten the nuts to 45 Nm (33 ft. lbs.) without turning the crankshaft so you do not smudge the Plastigage. Unscrew the bearing cap and measure the compressed Plastigage to get the bearing to journal clearance; it should be the same clearance along the entire width of the insert. If the clearance is larger than what's needed, put in two 0.0254 mm (0.001 inch) smaller bearing inserts, always installing all odd size inserts on the bottom and recheck the clearance. With 0.001 inch undersize inserts, the initial 0.0762 mm (0.003 inch) clearance is brought to 0.002 inch and with 0.002 inch undersize inserts it decreases to 0.038 mm (0.0015 inch). Once again measure the bearing with Plastigage to be sure before putting together the final assembly. After picking the proper insert, fit it and the cap, adjusting the connecting rod bolts to 45 Nm (33 ft. lbs.) and mushroom a nice fitting feeler gauge between the connecting rod and crankshaft journal flange. If the gaps are not ideal, change the connecting rod.