JeepParts

My Garage

My Account

Cart

OEM 2000 Jeep Wrangler Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Brake Lines found

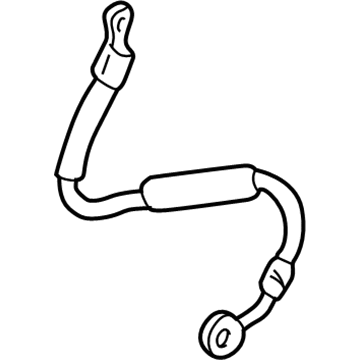

2000 Jeep Wrangler Flex Hose, Front Driver Side Part Number: 52008675AD

$367.19 MSRP: $422.00You Save: $54.81 (13%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Line - Brake; Brake Hydraulic Hose, Front Left; Hydraulic Hose; Brake Hose; Brake Line; Master Cylinder Repair Kit

- Position: Front Driver Side

- Replaces: 52008675AC

- Item Weight: 0.80 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52008675AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Jeep Wrangler Flex Hose, Front Passenger Side Part Number: 52008674AD

$361.60 MSRP: $415.00You Save: $53.40 (13%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Line - Brake; Brake Hydraulic Hose, Front Right; Hydraulic Hose; Brake Hose; Brake Line; Master Cylinder Repair Kit

- Position: Front Passenger Side

- Replaces: 52008674AC

- Item Weight: 0.80 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52008674AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

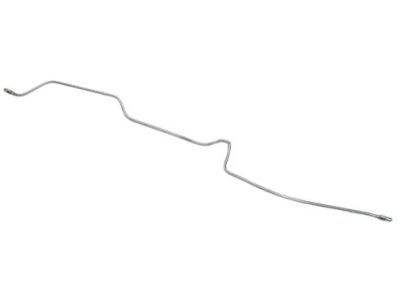

2000 Jeep Wrangler Brake Tube, Rear Passenger Side Part Number: 52008402

$64.73 MSRP: $97.05You Save: $32.32 (34%)Product Specifications- Other Name: Line - Brake; Brake Hydraulic Line, Rear Right; Brake Hose; Brake Line; Tube Brake

- Position: Rear Passenger Side

- Item Weight: 0.80 Pounds

- Item Dimensions: 37.4 x 4.2 x 3.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52008402

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

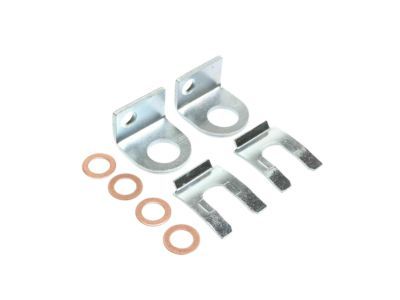

2000 Jeep Wrangler Flex Hose, Rear Center Part Number: 52008391AB

Product Specifications- Other Name: Line - Brake; Brake Hydraulic Hose, Rear Center; Hydraulic Hose; Brake Hose; Brake Line

- Position: Rear Center

- Replaces: 52008391

- Item Weight: 1.20 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52008391AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

Product Specifications

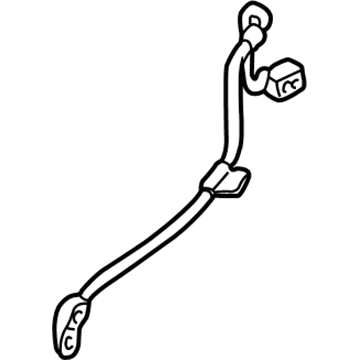

Product Specifications- Other Name: Line - Brake; Brake Hydraulic Line, Rear Left; Brake Hose; Brake Line; Tube Brake

- Position: Rear Driver Side

- Replaces: 52008403AC

- Item Weight: 0.50 Pounds

- Item Dimensions: 20.0 x 3.1 x 2.1 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 52008403AD

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2000 Jeep Wrangler Brake Line Parts and Q&A

- Q: How Should You Service and Repair a Brake Line on 2000 Jeep Wrangler?A: To fix brake line service and repair, brake manufacturers improve steel as standard or double wall steel can be used if your vehicle is out of a part from the manufacturer. Brake tube bending is only possible with the right equipment and flaring the tubes requires specific equipment as well. Double inverted flaring is done by using a Tubing Cutter on the damaged tube and reaming the cut ends to perfect the flare. Fasten the tube nut unto the tube, slip the tube into the flaring tool and position the gauge form on the end of the tube. Pull the tube into the flaring tool mouth all the way to where it fits into the matching recessed section in the gauge, then tighten on the tool bar. Put the thin end of the tube plug into the gauge, flare the compression disc and fit it over the gauge and then place the throttle body screw into the recess of the compression disc. After square-setting the plug gauge on the jaws with the handle in place, remove the plug gauge and finish the inverted flare. An optimum ISO flaring technique is the use of the Snap-On(R) Flaring Tool TFM-428 or something functionally equivalent. Use a Tubing Cutter to remove the damage tube, get rid of any burrs within the tube and set the tube nut onto the tube. In the flaring tool, line up the center of the tube with the top end of the tool bar and tighten the bar down to the tube. Screw the adaptor corresponding to the tool bar into the flaring tool yoke screw, coat the adaptor with a little lubricant, fit the adaptor over the tube and tighten the yoke screw until it is flush on the bar.