JeepParts

My Garage

My Account

Cart

OEM 2004 Chrysler Pacifica Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Brake Calipers found

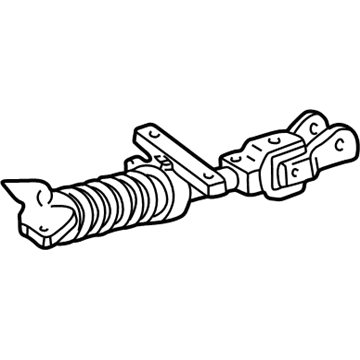

2004 Chrysler Pacifica Steering Column Part Number: 5066106AC

Product Specifications- Other Name: Column - Steering; Column Assembly; Caliper

- Replaces: 5066106AB, 5103440AA

- Item Weight: 14.40 Pounds

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5066106AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

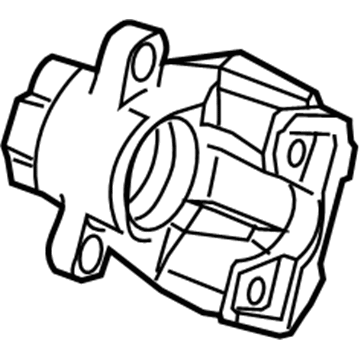

- Product Specifications

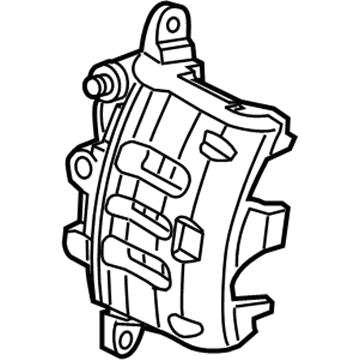

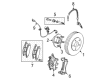

- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Right; Caliper Disc Brake; Brake Caliper

- Position: Rear Passenger Side

- Item Weight: 5.80 Pounds

- Item Dimensions: 5.1 x 5.2 x 7.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5114440AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

- Product Specifications

- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Rear Left; Caliper Disc Brake; Brake Caliper

- Position: Rear Driver Side

- Item Weight: 5.90 Pounds

- Item Dimensions: 7.4 x 5.4 x 3.3 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5114441AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

- Product Specifications

- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Left; Caliper Disc Brake; Brake Caliper

- Position: Front Driver Side

- Item Weight: 12.50 Pounds

- Item Dimensions: 10.3 x 7.5 x 5.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5103119AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

- Product Specifications

- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Right; Caliper Disc Brake; Brake Caliper

- Position: Front Passenger Side

- Item Weight: 11.60 Pounds

- Item Dimensions: 10.2 x 7.7 x 5.2 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5103118AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2004 Chrysler Pacifica Brake Caliper Parts and Q&A

- Q: How to Service and Repair a Rear Disc Brake Caliper on 2004 Chrysler Pacifica?A: Disconnect and set aside the negative battery cable as the very first thing to do when you have to service or repair the rear disc brake caliper. Put the brake pedal holding tool through the brake pedal, depressing it past its first inch, to prevent the master cylinder from being connected to the hydraulic brake system. Prop up the car and disconnect and take out the removed wheel and its tire. Separate the banjo bolt and throw away the two washers, as you are going to install new ones. Then, take out the guide pin bolts from the caliper and swing the bottom of the caliper toward the wheel so that you can lift the caliper off the brake adapter on top. Push the brake shoe so it's separated from the caliper fingers and unlatch the locating pins, after which you can slide it off. Pull the inboard brake shoe back from the caliper to knock out and remove the clip. For disassembly, give the caliper a good clean and check it over, then push the guide pin bushing sleeve towards the back of the caliper and remove it by pulling. Remove the rubber guide pin bushing by first compressing one end and extracting it from the other. For removing the piston, secure the caliper using protective jaws in a vise, put a block in the caliper and gently shoot low pressure compressed air at it to ease the piston out. Get rid of the old piston seal by pulling it out with a soft tool, after you discard the dust boot. Clean the area around the piston and look for any signs of scoring or pitting; for light scratches, use a crocus cloth to smooth them out. To clean, mist the brakes with water, wipe them with a damp cloth and dispose of any asbestos fibers. Check the caliper for signs of fluid leaks, possible damage to the dust boot and inspect the dust boots surrounding the guide pin. If issues appear, disassembly and repacking of the caliper is necessary and seals and dampers should be exchanged when needed. Fold the guide pin bushing in half, then put it in the caliper mounting boss and press it in until it is all the way seated. Coat the inner walls of the bushing and then put in the guide pin sleeve. Add clean brake fluid to the pistons, seals and bores, fit the new piston seal in place next and make sure the boot is seated properly before installing everything. Insert the piston into the caliper bore and use Installer, Special Tool 9089 and Handle, Special Tool C-4171, to place the dust boot. Install both the bleeder screw and caliper on the vehicle, so the piston does not extend and the inboard shoe retainer clip is in place. Put the outboard brake shoe in place and check that the abutment shims are present. Carefully put on the caliper, ensuring its guide pin bolts do not go in at a wrong angle and then tighten them to 23 Nm (200 inch lbs.). Put on new washers, slide them in and then tighten the banjo bolt to 47 Nm (35 ft. lbs.). Attach the tire and wheel assembly, tighten the wheel nuts to 135 Nm (100 ft. lbs.), put the vehicle back on the ground, remove the brake pedal tool, link the negative battery cable and bleed the brake system when needed and take a road drive to test it.