JeepParts

My Garage

My Account

Cart

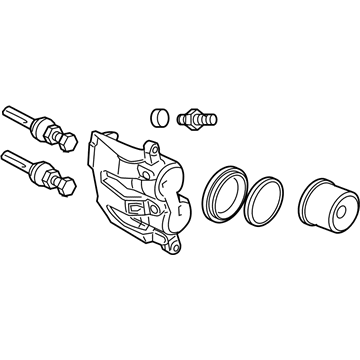

OEM 2005 Dodge Dakota Brake Caliper

Caliper- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Brake Calipers found

2005 Dodge Dakota Caliper, Front Passenger Side Part Number: 5143348AC

$53.43 MSRP: $76.20You Save: $22.77 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Right; Caliper Disc Brake; Brake Caliper

- Position: Front Passenger Side

- Item Weight: 11.50 Pounds

- Item Dimensions: 12.3 x 6.0 x 4.7 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5143348AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Dodge Dakota Caliper, Front Driver Side Part Number: 5143358AC

$42.53 MSRP: $60.50You Save: $17.97 (30%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Caliper - Disc Brake; Disc Brake Caliper, Front Left; Caliper Disc Brake; Brake Caliper

- Position: Front Driver Side

- Item Weight: 11.40 Pounds

- Item Dimensions: 12.3 x 6.1 x 4.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5143358AC

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Dodge Dakota Brake Caliper Parts and Q&A

- Q: How to Effectively Service and Repair Brake Calipers on 2005 Dodge Dakota?A: Service and repairs on the disc brake calipers can be done by doing the following; the first step is to raise and support the vehicle, followed by the removal of the tire and wheel assembly. Squeeze the disc brake caliper and unbolt the banjo bolt and get rid of the copper washers, the caliper slide pin bolts and release the caliper using the caliper slide pin bolts. Take out the caliper slip pins in the adapter. Remove the brake fluid in the caliper, then put a C-clamp with block of wood on one of the pistons and another padded piece of wood in front of the other piston to shield the latter as it is removed. To remove the first piston, apply quick bursts of low pressure air in the caliper brake hose port to push out the piston taking care not to apply more than a momentary burst of pressure lest this causes the piston to crack. Once the first piston has been removed seal the vacant bore with the C-clamp and piece of wood and repeat same procedure on the second piston. The piston dust boots are removed manually without damaging the piston bore and the lip seal removed on the piston followed by the piston seals using a pick tool. Examine the pistons and look out to see whether there is a crack or scoring in the piston and in case there is a replacement that may be required, then replace it with the same kind of piston. On lightly polish the bore with a brake hone in case of minor imperfections but replace the caliper in case of gross corrosion or in the case part of the bore polishes out more than 0.025 mm. To install, make sure that the area you are working is dry and clean, lubricate the caliper pistons, seal of piston and the bores by clean brake fluid, put the new piston seals in the caliper bores. Place the dust boot over the piston keeping the lips inserted in front of the piston before pushing the lips into the groove using a proper tool and insert the piston into the bore until it seat with another special tool C3716-A using C-4171 Handle. Make sure that the bellow of the dust boots does not have air in it. Petroleum-based grease should not be used on rubber parts and only the greater quantity of non-petroleum-based grease should be used, clean the slide-pin holes before installation. Apply new slide pins on all working surfaces and fit the boot on the slide pin and its installation into the adapter by pushing the trapped air out of the boot by pressing on it lightly. Put on a new copper washer on the banjo bolt, put the disc brake caliper on the brake caliper adapter and use new copper washers to secure the banjo bolt and tighten around 28 Nm. Fit the caliper slide pin bolt and tighten to 32 Nm, bleed the base brake, refit the tire and wheel assembly and lower vehicle.