JeepParts

My Garage

My Account

Cart

OEM Chrysler Alignment Bolt

Control Arm Bolt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Alignment Bolts found

Chrysler Strut Rod Mount Bolt, Rear Part Number: 6507107AA

$9.86 MSRP: $14.35You Save: $4.49 (32%)Product Specifications- Other Name: Bolt - Hexagon Head; Suspension Control Arm Bolt, Rear Upper Outer; Strut Rod Bolt; Strut Rod Rear Bolt M12X1.75X75.00; Hexagon Head Toe Link To Knuckle.

- Position: Rear

Chrysler Lower Control Arm Bolt, Front Part Number: 6507575AA

$9.92 MSRP: $14.45You Save: $4.53 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Screw - Hexagon Flange Head; Suspension Control Arm Bolts (Front Lower, Upper, Lower) & Lateral Arm Bolt (Front); Control Arm Bolt; M14X2.00X100.00 Hexagon Flange Head Screw; various control arm bolts.

- Position: Front Lower

- Replaces: 6507812AA, 6503068

Chrysler Lower Control Arm Bolt, Rear Part Number: 6511304AA

$10.61 MSRP: $15.75You Save: $5.14 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bolt & Retainer - Hexagon Head; Rear Camber Adjusting Eccentric Bolt; Control Arm Bolt; Alignment Kit; Lower Control Arm Adjust Bolt; M12X1.50X91.00 & M12X1.50X96.00 Hexagon Head Bolts.

- Position: Rear

- Replaces: 6510789AA

Chrysler Lower Control Arm Bolt, Front Part Number: 6507089AA

$14.79 MSRP: $21.50You Save: $6.71 (32%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Bolt - Hexagon Head; Suspension Control Arm Bolt, Front Lower, Lower, Outer; Camber Bolt Kit; Lower Control Arm Front Bolt; M14X2.00X120.00 bolts and screws for control arm mounting.

- Position: Front Lower

Chrysler Bolt - Hexagon Flange Head Part Number: 6512608AA

$12.77 MSRP: $18.70You Save: $5.93 (32%)Ships in 1-2 Business DaysProduct Specifications- Other Name: BOLT-HEX FLANGE HEAD

Chrysler Lower Control Arm Lower Bolt, Rear Part Number: 5098775AA

$14.40 MSRP: $18.25You Save: $3.85 (22%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bolt - Control Arm Cam; Suspension Control Arm Bolt, Rear Lower; Bolt Control Arm Cam

- Position: Rear Lower

Chrysler Lower Control Arm Bolt, Upper Part Number: 6511255AA

$4.70 MSRP: $6.95You Save: $2.25 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bolt - Hexagon Flange Head; Suspension Control Arm Bolt, Lower, Upper; Upper Control Arm Bolt; M12X1.50X81.50 Hexagon Flange Head Bolt and Washer.

- Position: Upper

Chrysler Lower Control Arm Upper Bolt, Rear Part Number: 5099812AA

Product Specifications- Other Name: Bolt - Control Arm Cam; Suspension Control Arm Bolt, Rear Upper; Bolt Control Arm Cam

- Position: Rear Upper

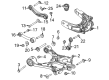

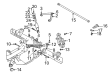

Chrysler Alignment Bolt

OEM parts sourced directly from Chrysler deliver superior quality, long lasting strength, and a precise fit you can trust. Each item goes through strict quality checks to ensure safety, toughness, and performance that matches your factory equipment. At JeepPartsDeal online shop, you'll get top-quality, budget-friendly OEM Chrysler Alignment Bolt for your vehicle. We focus on giving you a high standard without pushing up the price. Our full selection of genuine factory products comes backed by the original manufacturer's warranty. You'll love our fast delivery, seamless shopping experience, and convenient return policy, saving you all the hassle.

The Chrysler Alignment Bolt allows you to adjust the camber and caster of the wheels to make your car move straight, tires wear even, and each drive will remain stable and predictable. Chrysler has earned loyalty by creating strong cars since 1925 that balance on value and clever engineering like Floating Power which helps to eliminate engine vibration, smooth Airflow which flattens the wind, and the first sensible minivan which offers family roomy comfort. Chrysler continues to upgrade the interior space, ride comfort and utility to an everyday use to ensure that both the driver and the passengers do not complain about spending any miles in traffic. These strong points imply that a Chrysler is calm, and the very accuracy of the work of an Alignment Bolt keeps it calm. The special suspension fastener is an Alignment Bolt, which has an off-center cam, and it is a simple part that provides such small yet critical range of adjustment that it re-aligns the suspension angles to factory standards. To mount the Chrysler Alignment Bolt you have to park on a level road, then place the parking brake and lift the part you will work on. Take out the wheel, locate the strut-to-knuckle or control-arm joint, rough out its present location, loosen the factory hardware, and move it out. Insert the new Alignment Bolt, point the cam towards a direction which eliminates the camber and spin the nut with your fingers. Bring it to normal level, rotate the bell head until the reading is correct, and torque to the specification, then carefully reattach the wheel and make a brief test drive to verify that it is straight tracking.