JeepParts

My Garage

My Account

Cart

OEM Chrysler PT Cruiser Piston

Engine Pistons- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Pistons found

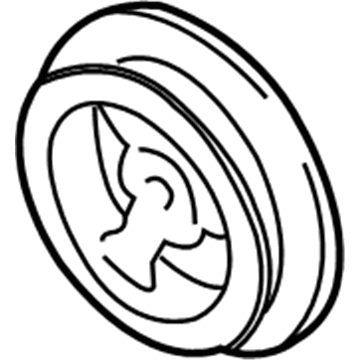

Chrysler PT Cruiser Vibration Damper Part Number: 5142303AB

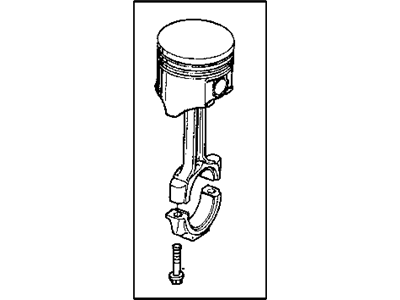

$56.55 MSRP: $81.25You Save: $24.70 (31%)Ships in 1-3 Business DaysChrysler PT Cruiser Piston Part Number: 68086046AB

$105.19 MSRP: $134.00You Save: $28.81 (22%)Ships in 1-2 Business DaysChrysler PT Cruiser Piston Part Number: 4884247AD

Chrysler PT Cruiser Piston

Choose OEM Piston that meet Chrysler factory standards. Chrysler designs and tests every component for precision and durability. Each Piston follows strict manufacturing steps to lock in quality and fit. If your Chrysler PT Cruiser matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine PT Cruiser parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Piston in Chrysler PT Cruiser automobiles has the function of converting power resulting from combustion into the energy required in the motion of vehicles. This component is inherent to internal combustion engine as it translate forces exerted by expanding gasses to the crankshaft. Standard Chrysler PT Cruiser pistons are made out of aluminum alloy in an attempt to provide both strength as well as a low weight, and more focused performance versions of the car may be using forged or billet pistons. With regard to pistons, various types have been used in Chrysler PT Cruiser vehicles, trunk pistons, which absorb side loads and have provided oil rings. The basic design is thus most often kept constant, although there can be variations with regards to the conditions of operation. The manufacturing of Chrysler PT Cruiser piston is highly engineered so as to withstand the higher pressure and high temperature thus helping in increasing efficiency and life of the vehicle.

Chrysler PT Cruiser Piston Parts and Q&A

- Q: How to Remove and Replace a Piston and Connecting Rod on Chrysler PT Cruiser?A:Before replacing the piston and connecting rod, take off the cylinder head, Oil Pan (3) and Balance Shaft Carrier Assembly. Guide a reliable ridge reamer around the cylinder bore, ensuring it doesn't touch or cut off the tops of the pistons. You should notice that the pistons have a stamping that shows the front half facing the engine's front. Take out the pistons and connecting rods on top of the cylinder block after rotating the Crankshaft to make sure each piston is in its correct place in the bore. Write on each connecting rod cap with permanent marker instead of making a number stamp to avoid ruining the surface. Take out the connecting rod bolts and the cap without hurting the fracture rod or cap; leave the bolts where you find them. It's important not to damage the oil jet during removal, especially if your engine is turbocharged. Set Connecting Rod Guides 8189 on the connecting rod and, by hand, push every piston-rod combination out of the cylinder bore so as not to damage the crankshaft. After you've removed the guides, reposition the bearing cap back on the mating rod, because pistons and rods are always handled this way. Do this for every piston and connecting rod and after that, remove the piston rings. For installation, first put the piston rings on the piston, ensuring the gaps between the compression rings are different and the oil ring expanders touch each other. Drop the piston and rings in engine oil, then put the ring compressor in place on the piston to keep the ring spots in the same position. If you are going to install a piston/rod that has been used, put it in the same position it was in before and point 1 (the directional stamp) towards the front of the engine. Adjust the crankshaft so that a connecting rod journal centers within the cylinder bore and grease it with clean oil after adjustment. Secure the top bearing part onto the connecting rod and then slide the Connecting Rod Guides 8189 into the rod as well. Tap the piston with a hammer handle, making sure the connecting rod lines up with the journal as it goes down. Take out the guides carefully and don't try to use the rod bolts again. Apply a bit of clean engine oil to the threads of the bolts, then place the lower bearing part into the connecting rod cap and fasten the cap into place. Finger tighten all bolted pieces, then tighten each bolt to 27 Nm (20 ft. lbs.) in a sequence, followed by turning each more than 1/4 further without torque. Ap-proximate the connecting rod side clearance, install the Balance Shaft Carrier Assembly, refasten the oil pan (3) and also reinstall the cylinder head. Check the engine after that to make sure there are no leaks.

- Q: How to Install Piston and Connecting Rod Assemblies on Chrysler PT Cruiser?A:Before installing the piston and connecting rod, first put the rings onto the piston with the gaps in the compression ring not aligned with the oil ring rail gap. Before using the ring compressor, make sure the oil ring expander ends are aligned and the rail gaps are correct. Place the piston head and rings in clean engine oil, fit the ring compressor over the piston and make sure you don't move the rings out of place. Whenever using a used piston/rod assembly, be sure to position it as it was made, with the stamp on the piston pointing toward the front of the engine. Crank the rotor to bring the connecting rod journal align with the center of the cylinder bore and apply clean engine oil to it. Slide the connecting rod upper bearing half into the connecting rod and then fix Connecting Rod Guides 8189 onto the connecting rod. Use a hammer handle to drive the piston down into the cylinder bore while adjusting the connecting rod on the connecting rod journal, then take out the Connecting Rod Guides 8189. Rather than reusing the connecting rod cap bolts, thread new bolts lightly with clean oil. Fit the lower half of the bearing into the connecting rod end and place the cap on. Tighten all the bolts by hand and then go around torquing them to 27 Nm (20 ft. lbs.) and a 1/4 additional turn without using a torque wrench for the second step. Measuring the connecting rod side clearance with a feeler gauge is necessary. After that, set up the Balance Shaft Carrier Assembly, install the Oil Pan and assemble the cylinder head. After all, begin the engine and look for any leaks.