JeepParts

My Garage

My Account

Cart

OEM Dodge Ram 3500 Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

6 Flywheels found

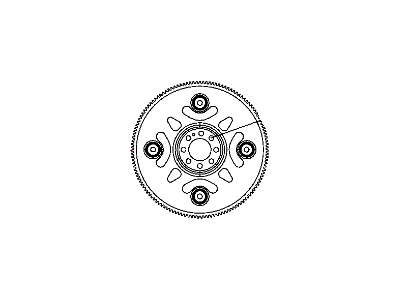

Dodge Ram 3500 Flywheel Part Number: 52104721AG

$945.88 MSRP: $1440.00You Save: $494.12 (35%)

Dodge Ram 3500 Flywheel Part Number: 53022042AA

$198.28 MSRP: $293.00You Save: $94.72 (33%)Ships in 1-2 Business DaysDodge Ram 3500 Flywheel Part Number: 53020585

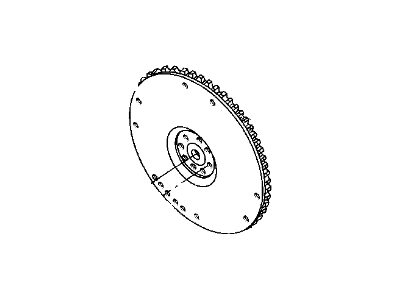

Dodge Ram 3500 Flywheel Part Number: 53006216AC

Dodge Ram 3500 Flywheel Part Number: 5018079AC

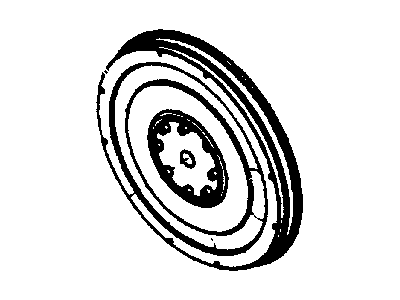

Dodge Ram 3500 Flywheel Part Number: 5015624AA

Dodge Ram 3500 Flywheel

Choose OEM Flywheel that meet Dodge factory standards. Dodge designs and tests every component for precision and durability. Each Flywheel follows strict manufacturing steps to lock in quality and fit. If your Dodge Ram 3500 matters to you, OEM parts make the smart choice. You'll get the exact look, feel, and performance you expect. Shop genuine Ram 3500 parts at the highly competitive prices online. Enjoy a manufacturer's warranty, a hassle-free return policy, and rapid delivery. No more guesswork with off brands. Get genuine parts with exact fit and true factory performance. Shop with confidence today at JeepPartsDeal.com.

Dodge Ram 3500 Flywheel Parts and Q&A

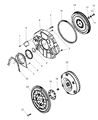

- Q: How to Address Worn or Damaged Flywheel Teeth on Dodge Ram 3500?A:If one or more teeth on the flywheel are missing or broken, the whole flywheel should be replaced. Replacement ring gears may be used in place of a new flywheel for V10 or Diesel Engine models, but you need to follow exact steps to stop damage from occurring. Begin by finding out the position of the old gear on the flywheel by drawing lines with a scriber. With an abrasive cut-off wheel, cut the old gear mostly through at one place and then remove what's left by striking it with a cold chisel or punch. Since the ring gear attaches by shrink fit to the flywheel, it has to be warmed to expand it for the installation process. You should heat the whole gear, using an enclosed oven at about 375°F to make sure the heat is even. Do not heat it with an oxy/acetylene torch, since the heat will not be even and can quicken wear of the gear. When working with a hot ring gear, always use goggles or safety glasses and heat-resistant gloves. Make sure to spread out the heated gear evenly so it doesn't become distorted or crooked by adding it slowly using a shop press and the right press plates. Set the flywheel on a workbench and let it cool while the ring gear inside is still exposed to normal shop air. Water is not allowed for cooling, since fast cooling can damage the new gear.

- Q: How to Install a Flywheel or Flexplate for Automatic Transmissions on Dodge Ram 3500?A:Align the flywheel or flexplate to the Crankshaft and for now screw in the bolts loosely by hand. When using an automatic transmission, fasten the flexplate retaining bolts to 95 Nm (70 ft. lbs.). Following this, put in the transmission.