JeepParts

My Garage

My Account

Cart

OEM 2005 Dodge Durango Rod Bearing

Engine Connecting Rod Bearing- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Rod Bearings found

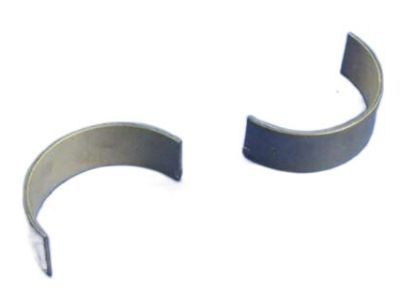

2005 Dodge Durango Connecting Rod Bearing Part Number: 68207790AA

$6.32 MSRP: $7.70You Save: $1.38 (18%)Product Specifications- Other Name: Bearing Package - Connecting Rod; Rod Bearing; Bearing; Bearings; Bearing Kit Connecting Rod Standard

- Replaces: 5086003AB

- Item Weight: 0.50 Pounds

- Item Dimensions: 3.8 x 2.6 x 1.8 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 10

- SKU: 68207790AA

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

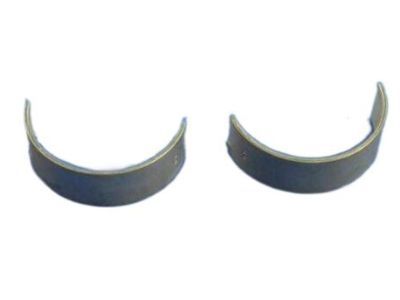

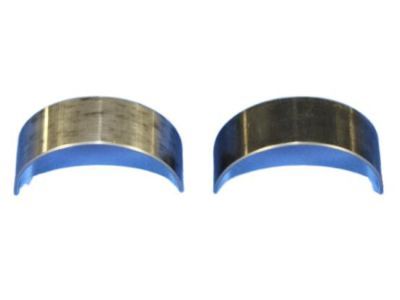

2005 Dodge Durango Bearings Part Number: 68052222AB

$18.13 MSRP: $26.80You Save: $8.67 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing - Connecting Rod; Engine Connecting Rod Bearing Set; Connecting Rod Bearing Set; Rod Bearing; Bearing Kit Connecting Rod Standard See Note

- Replaces: 5019447AA, 68052222AA

- Item Weight: 0.50 Pounds

- Item Dimensions: 3.9 x 2.6 x 2.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 6

- SKU: 68052222AB

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

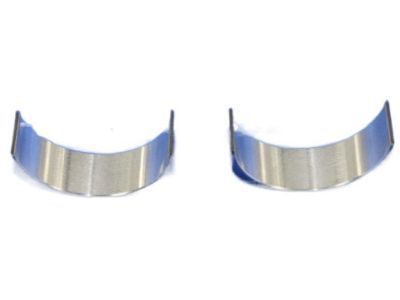

2005 Dodge Durango Bearings Part Number: 5012363AE

$16.87 MSRP: $25.00You Save: $8.13 (33%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Bearing - Connecting Rod; Rod Bearing; Bearing Kit Connecting Rod Standard See Note; Bearing Kit Connecting Rod Standard

- Replaces: 5012363AC, 5012363AD, 5018584AB, 5012363AB

- Item Weight: 0.50 Pounds

- Item Dimensions: 4.0 x 2.7 x 2.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 5012363AE

- Warranty: This genuine part is guaranteed by Mopar's factory warranty.

2005 Dodge Durango Rod Bearing Parts and Q&A

- Q: How to Inspect and Replace Rod Bearings on 2005 Dodge Durango?A: Look at the connecting rod bearings for signs of wear such as scoring, grooves, fatigue and pitting and replace any that seem different from the norm. Observe the surface of the connecting rod journals to check for scarring or burrs, as it is important to notice those since bent rods can lead to uneven wear on pistons, piston rings, cylinder walls, bearing rods and crankshaft connecting rods. Should the wear or areas of damage suggest a misaligned rod, check and replace anything that is not properly aligned. Clean the connecting rod journal from oil, smear the upper bearing insert and place it in the rod, ensuring it is centered. Choose two points to measure, as the distance between them must be 0.50 mm or less. Place a piston ring compressor on the cylinder and use Guide Pins Special Tool 8507 to fit the rod and piston assemblies. Make certain the oil slinger slots are toward the front of the engine and the "F" near the piston pin points the same way. Centering the lower bearing insert, dry it and put it in the bearing cap. Across the middle of the lower insert at the center of the bearing cap, position a strip of Plastigage to make sure it remains whole. Place the bearing cap and connecting rod on the journal, fasten the bolts until you get 27 Nm (20 ft. lbs.) and tighten 90° extra without turning the crankshaft to keep Plastigage from being smeared. Take off the bearing cap, then measure the thickness of the crushed Plastigage to see how much clearance there is between the bearing and journal and compare those measurements to the Engine Specifications. If the amount of clearance is not the same at each end, you might have a tapered journal, a bent connecting rod or debris between the insert and cap or rod. As long as the guidelines are met, you should not replace the needle bearings; indicated by the correct pull-out, remove the Plastigage and continue with the bearing installation. If the clearance between the bearing and the journal is greater than permitted, decide which bearing set to apply and since connecting rod bolts are Torque to Yield Bolts, always change them after loosening or removing them. Check Plastigage again to make sure you've selected the right bearings, then fit and tighten the bolts that hold the bearings to the same torque you used at the start, plus another 90-degree turn. Put a feeler gauge close to the flange area and check the side clearance against the engine's manual. Reinstall the connecting rod if it is out of specification.